Home> Company News> Exploring Maximum Capacity Ball Bearings: Precision Meets Power

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Maximum capacity ball bearings have revolutionized the field of engineering by offering a unique combination of precision and power. In this article, we will delve into the concept and significance of maximum capacity ball bearings, exploring how these remarkable components strike a delicate balance between precision and power.

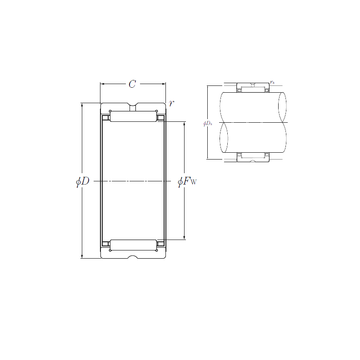

Maximum capacity ball bearings are a critical part of many mechanical systems, providing the ability to handle heavy loads while maintaining high levels of precision. These bearings are designed with a larger number of balls and a deeper groove in the inner and outer rings compared to standard ball bearings. This distinctive design allows them to carry heavier radial and thrust loads, making them ideal for applications where both precision and power are essential.

Design and Structure

In our quest to understand the fascinating world of maximum capacity ball bearings, let's dive into the unique design features and structural elements that set these bearings apart. It is in these intricacies that we discover how maximum capacity ball bearings manage to combine precision with power in a way that benefits a wide range of engineering applications.

At the heart of their design, maximum capacity ball bearings feature a larger number of balls than traditional ball bearings. These additional balls distribute the load more evenly, allowing for higher load-carrying capabilities. Additionally, the inner and outer rings of these bearings have a deeper groove, providing increased capacity for both radial and thrust loads.

The ball diameter in maximum capacity ball bearings is also larger, contributing to their impressive load-handling abilities. This design choice results in a greater contact area between the balls and the raceways, reducing stress and wear on the bearing components.

Furthermore, the cages used in these bearings play a crucial role in their overall design. Cages are typically made of various materials, such as steel or brass, and their primary function is to keep the balls evenly spaced and separated, ensuring smooth operation and reducing friction.

By exploring these unique design features and structural elements, we gain insight into how maximum capacity ball bearings achieve their remarkable balance of precision and power.

Applications Across Industries

In the world of engineering and machinery, precision and power often converge, and it's in this delicate balance that we find the extraordinary role of maximum capacity ball bearings. These remarkable bearings are utilized across a diverse spectrum of industries, each benefiting from their unique capabilities that seamlessly blend precision with power. Let's explore some of the key industries and applications where maximum capacity ball bearings shine.

|

Aerospace Industry |

In the aerospace sector, where reliability and precision are of utmost importance, maximum capacity ball bearings find extensive use. These bearings support various components of aircraft, from landing gear to engine systems, ensuring smooth and reliable operation under extreme conditions. |

|

Manufacturing and Automation |

Manufacturing facilities and automated production lines heavily rely on maximum capacity ball bearings for conveyor systems, robotics, and heavy machinery. These bearings help maintain the efficiency and precision required for high-speed manufacturing processes. |

|

Renewable Energy |

Wind turbines, solar tracking systems, and hydropower plants require bearings that can handle substantial loads while maintaining high precision. Maximum capacity ball bearings play a vital role in these renewable energy systems, contributing to their efficiency and reliability. |

|

Construction Equipment |

Heavy construction machinery, such as excavators, cranes, and bulldozers, benefit from the load-carrying capacity of these bearings. They ensure the robustness and longevity of these machines in demanding construction environments. |

|

Transportation |

Trains, trucks, and other forms of transportation rely on maximum capacity ball bearings for various components, including wheels, axles, and gearboxes. These bearings provide the durability needed for reliable transportation services. |

|

Medical Devices |

Precision and reliability are non-negotiable in the medical industry. Maximum capacity ball bearings are used in medical devices such as MRI machines and surgical equipment, where they contribute to the accuracy of diagnostic procedures and medical treatments. |

|

Oil and Gas |

In the oil and gas sector, where equipment operates in harsh and remote environments, these bearings are essential for critical components like pumps, compressors, and drilling equipment. They ensure the smooth operation of these machines in challenging conditions. |

|

Mining |

Mining operations involve heavy machinery and extreme loads. Maximum capacity ball bearings are used in crushers, conveyors, and ore processing equipment, where they withstand the punishing demands of the mining industry. |

|

Food and Beverage |

Conveyor systems in food processing plants rely on these bearings to handle heavy loads while maintaining hygiene standards. Their precision and load capacity make them ideal for this industry. |

|

Machine Tools |

Precision machine tools, such as milling machines and lathes, require maximum capacity ball bearings to achieve the accuracy and smoothness needed for intricate machining processes.

|

These are just a few examples of the myriad industries and applications where maximum capacity ball bearings play a pivotal role. Their ability to combine precision with power ensures the seamless operation of critical machinery and systems, ultimately driving progress and innovation across various sectors.

Selection and Installation

Maximum capacity ball bearings are engineering marvels that offer a unique blend of precision and power. To harness their full potential, it's crucial to understand how to select the right bearings for a particular application and ensure their proper installation. we will guide engineers and professionals on the selection and installation of maximum capacity ball bearings, emphasizing the factors to consider and best practices.

Bearing Selection:

When it comes to selecting maximum capacity ball bearings, one size does not fit all. Different applications demand specific bearing characteristics. Here are the key factors to consider:

- Load Capacity: Determine the maximum load the bearing will need to support. Maximum capacity ball bearings are designed to handle heavy radial and axial loads, making them suitable for applications with high-load requirements.

- Speed: Consider the rotational speed at which the bearing will operate. Maximum capacity ball bearings can accommodate moderate to high-speed applications, but it's essential to choose the right bearing type and lubrication to match the speed requirements.

- Precision: Precision is paramount in many applications. Assess the required level of precision, and choose bearings with appropriate tolerance classes to meet those demands.

- Temperature and Environment: Evaluate the operating environment for factors like temperature, humidity, and exposure to contaminants. Select bearings with the appropriate seals or shields to protect against environmental conditions.

- Lubrication: Proper lubrication is essential for bearing longevity and performance. Determine the lubrication method (grease or oil) and frequency of maintenance based on the application's demands.

Bearing Installation:

The correct installation of maximum capacity ball bearings is as crucial as selecting the right bearings. Here's a step-by-step guide:

- Cleanliness: Ensure the work area and components are clean and free of contaminants. Any dirt or debris can compromise the bearing's performance and lifespan.

- Fitting: Use the appropriate tools and techniques to mount the bearing onto the shaft and into the housing. Ensure the fit is neither too tight nor too loose, as it can lead to premature bearing failure.

- Alignment: Proper alignment of shafts and housings is critical. Misalignment can cause uneven loads on the bearing and result in excessive wear and noise.

- Preloading: Some applications may require preloading to eliminate play or axial clearance. Follow the manufacturer's recommendations for preload values.

- Sealing: If your application involves exposure to contaminants, use seals or shields to protect the bearing from foreign particles.

- Lubrication: Apply the appropriate lubricant according to the manufacturer's specifications. Ensure that the lubrication method and frequency are consistent with the application's requirements.

- Testing: After installation, conduct thorough testing to verify that the bearing is functioning correctly and within specified parameters.

By following these guidelines for bearing selection and installation, engineers and professionals can maximize the performance and longevity of maximum capacity ball bearings in their machinery and applications. Precision indeed meets power when these remarkable bearings are chosen and installed correctly. In the subsequent sections, we will delve into maintenance practices and future trends, providing a comprehensive understanding of their role in the world of engineering.

Maintenance and Longevity

As we delve deeper into the world of maximum capacity ball bearings, it's crucial to understand that their precision and power can only be fully realized when they are properly maintained. we will discuss maintenance practices that ensure the extended lifespan and optimal performance of maximum capacity ball bearings. Additionally, we will highlight common issues that may arise during their operation and provide valuable troubleshooting tips.

Maintenance Practices:

Regular Inspection: Routine inspection of maximum capacity ball bearings is essential. Engineers and maintenance professionals should check for signs of wear, damage, or misalignment. This inspection should encompass the entire bearing assembly, including seals, cages, and lubrication.

Lubrication: Proper lubrication is paramount for the smooth operation of bearings. Depending on the application, bearings may require either grease or oil lubrication. Engineers should adhere to the manufacturer's recommendations regarding the type of lubricant, its quantity, and the lubrication intervals.

Temperature Monitoring: Bearings can overheat due to excessive friction or inadequate lubrication. Employ temperature monitoring devices to ensure that the bearing operates within a safe temperature range. Any significant deviations from the norm should be investigated promptly.

Alignment: Misalignment is a common issue that can lead to premature bearing failure. Regularly check and adjust the alignment of shafts and housings to ensure that loads are distributed evenly across the bearing.

Sealing: Ensure that seals or shields are intact and effectively prevent the ingress of contaminants. Damaged seals can lead to contamination, which can accelerate wear and reduce bearing life.

Common Issues and Troubleshooting:

Excessive Noise: Unusual noise during bearing operation is often an indication of problems. It can result from misalignment, insufficient lubrication, or contamination. Identify the source of the noise and address it promptly.

Vibration: Excessive vibration can lead to bearing damage and reduced precision. Conduct vibration analysis to pinpoint the cause, which could be misalignment, imbalance, or resonance.

Overheating: Overheating can cause lubricant breakdown and bearing failure. If a bearing runs too hot, investigate the root cause, which may include overloading, inadequate lubrication, or misalignment.

Fretting Corrosion: This form of corrosion occurs due to micro-movements at the contact points between bearing components. It can be mitigated through proper lubrication and the use of anti-fretting agents.

In conclusion, the longevity and precision of maximum capacity ball bearings can be maintained through diligent maintenance practices and prompt troubleshooting. Regular inspection, proper lubrication, temperature monitoring, and alignment checks are vital components of an effective maintenance regimen. By addressing common issues promptly and applying troubleshooting techniques, engineers can ensure that these bearings continue to meet the demands of precision and power in their applications.

Future Innovations and Trends

As we conclude our exploration of maximum capacity ball bearings, we turn our attention to the exciting realm of future innovations and trends in this field. The world of engineering and machinery is constantly evolving, and maximum capacity ball bearings are no exception. In this section, we will delve into the latest advancements and innovations in maximum capacity ball bearing technology and discuss how emerging trends are shaping the future of these remarkable components.

|

Advanced Materials |

One of the key areas of innovation in maximum capacity ball bearing technology is the development of advanced materials. Engineers and researchers are continually exploring new materials that can enhance the performance and longevity of these bearings. For instance, the incorporation of advanced ceramics can offer superior wear resistance and reduced friction, leading to enhanced precision and power. |

|

Miniaturization |

In an era where miniaturization is a prevailing trend, maximum capacity ball bearings are not left behind. Innovations in miniaturization techniques have enabled the creation of smaller, yet equally powerful bearings. These miniature bearings find applications in industries such as robotics, aerospace, and medical devices, where space constraints are significant. |

|

Smart Bearings |

The advent of the Internet of Things (IoT) has opened up new possibilities for maximum capacity ball bearings. Smart bearings equipped with sensors and monitoring capabilities can provide real-time data on their condition and performance. This data can be invaluable for predictive maintenance, allowing engineers to address issues before they lead to costly failures. |

|

Sustainable Lubrication |

With a growing focus on sustainability and environmental responsibility, innovations in lubrication techniques are emerging. Bio-based and environmentally friendly lubricants are being developed to reduce the ecological footprint of machinery that relies on maximum capacity ball bearings. |

|

Customization and 3D Printing |

The ability to customize maximum capacity ball bearings for specific applications is becoming more accessible with 3D printing technology. Engineers can design bearings tailored to unique requirements, optimizing precision and power delivery. |

|

Industry 0 Integration |

Industry 0 principles, including automation and data exchange, are increasingly being integrated into the manufacturing and operation of machinery. Maximum capacity ball bearings play a vital role in this evolution, providing the necessary precision and power for automated systems. |

|

Cross-Industry Applications |

The versatility of maximum capacity ball bearings allows them to transcend traditional industries. We are witnessing their adoption in diverse sectors, including renewable energy, automotive, aerospace, and even consumer electronics. Their ability to deliver precision while handling high loads makes them invaluable in a wide range of applications. |

In conclusion, maximum capacity ball bearings are poised for an exciting future filled with innovation and technological advancements. As engineers and researchers continue to push the boundaries of what these bearings can achieve, the implications for various industries are substantial. Whether it's through the use of advanced materials, smart technologies, or sustainable practices, maximum capacity ball bearings are set to continue playing a pivotal role in precision and power across the engineering landscape.

With this glimpse into the future of maximum capacity ball bearings, we wrap up our journey through the world of precision meeting power. We hope this exploration has provided you with valuable insights into these remarkable components and their significance in modern machinery.

Conclusion

In conclusion, our exploration of maximum capacity ball bearings has shed light on their pivotal role in the world of engineering, where precision meets power. These remarkable components have demonstrated their ability to handle high loads while maintaining exceptional precision, making them indispensable in a wide range of industries and applications.

As we've delved into their design, structure, applications across industries, selection, installation, maintenance, and future innovations, several key takeaways emerge:

Precision and Power: Maximum capacity ball bearings offer a unique balance between precision and power. Their design allows them to handle heavy loads without sacrificing accuracy, making them ideal for critical applications.

Wide Application Spectrum: These bearings find applications across a diverse spectrum of industries, from manufacturing and robotics to aerospace and renewable energy. Their versatility is a testament to their adaptability and performance.

Proper Selection and Maintenance: Engineers and professionals must pay careful attention to the selection and maintenance of maximum capacity ball bearings to ensure optimal performance and longevity. Proper lubrication, alignment, and monitoring are crucial factors in achieving this goal.

Future Possibilities: The future of maximum capacity ball bearings is bright, with ongoing innovations in materials, miniaturization, smart technologies, and customization. These advancements are set to enhance their performance and applicability even further.

In light of these takeaways, we encourage engineers, researchers, and professionals to continue exploring the possibilities of maximum capacity ball bearings in their respective fields. These bearings have proven time and again that they are a valuable asset when precision and power are paramount.

As we wrap up our journey through the world of maximum capacity ball bearings, we invite you to consider how these components can contribute to the success of your mechanical systems. Their potential to optimize performance, improve reliability, and reduce maintenance costs makes them a worthy investment.

Precision indeed meets power in the realm of maximum capacity ball bearings, and their impact on the world of engineering is undeniable. Embrace the opportunities they offer, and let these bearings drive your machinery to new levels of excellence.

FAQs: Common Questions About Maximum Capacity Ball Bearings

As we conclude our exploration of maximum capacity ball bearings and their vital role in precision and power, it's natural to address some common questions that may arise. These FAQs aim to provide clarity and insights into these remarkable engineering components.

What Are Maximum Capacity Ball Bearings?

Maximum capacity ball bearings are specialized bearings designed to handle higher radial loads than standard deep groove ball bearings. They achieve this by having more ball bearings within the bearing assembly and optimizing the internal design to accommodate larger loads while maintaining precision.

What Sets Maximum Capacity Ball Bearings Apart From Standard Bearings?

The key differentiator is their ability to handle significantly higher loads without sacrificing precision. Standard ball bearings may deform or fail under heavy loads, but maximum capacity ball bearings are engineered to excel in such conditions.

Where Are Maximum Capacity Ball Bearings Commonly Used?

These bearings find applications in various industries, including heavy machinery, conveyor systems, automotive transmissions, industrial gearboxes, and mining equipment. Any application that requires both high load-bearing capacity and precision benefits from these bearings.

How Can I Select the Right Maximum Capacity Ball Bearings?

Selecting the right bearings involves considering factors like load requirements, operating conditions, speed, and alignment. Consulting with bearing manufacturers or experts is advisable to ensure the best choice for your specific application.

What Maintenance Practices Are Essential for Maximum Capacity Ball Bearings?

Maintenance is crucial to maximize the lifespan and performance of these bearings. Regular lubrication, proper alignment, and monitoring for signs of wear or damage are essential practices. Follow the manufacturer's guidelines for maintenance intervals and procedures.

Are Maximum Capacity Ball Bearings Suitable for High-Speed Applications?

While these bearings are primarily designed for high-load applications, they can also operate at moderate speeds. However, for extremely high-speed applications, specialized bearings may be more appropriate, and consultation with experts is recommended.

What Does the Future Hold for Maximum Capacity Ball Bearings?

The future of these bearings is promising, with ongoing research and development focused on improving materials, reducing friction, enhancing sealing technologies, and incorporating smart features. These innovations will expand their capabilities and make them even more versatile.

In conclusion, maximum capacity ball bearings are a remarkable engineering solution that bridges the gap between precision and power. They have found their place in a wide range of industries and continue to evolve with advancements in technology. If you have further questions or require specific guidance on these bearings, don't hesitate to reach out to experts or manufacturers who can provide tailored solutions for your needs.

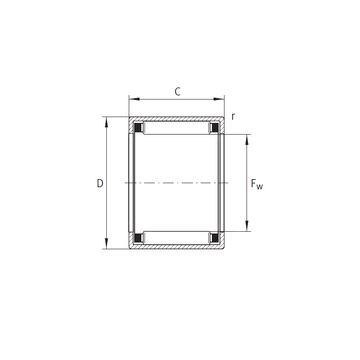

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

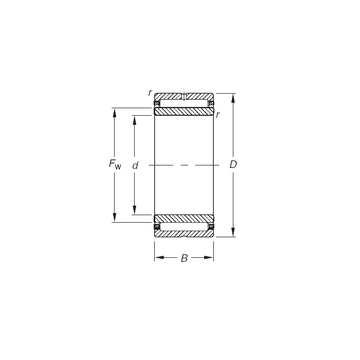

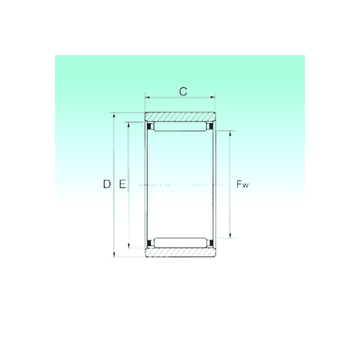

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

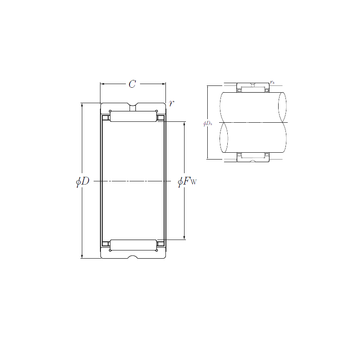

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings