Home> Company News> The Role of Flanged Housings in Bearing and Machinery Applications

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

1 Introduction

Flanged housings play a pivotal role in the world of bearings and machinery, serving as crucial components in a wide array of industrial applications.

Flanged housings, as the name suggests, are specialized enclosures or casings with flanges designed to provide essential support, protection, and alignment to bearings and other machinery components. These components are fundamental in ensuring the efficient operation of various machinery, ranging from heavy industrial equipment to precision instruments.

2 Types and Designs of Flanged Housings

Flanged housings come in a variety of types and designs, each tailored to meet specific requirements in bearing and machinery applications. Understanding these diverse configurations is essential in optimizing the performance and reliability of the equipment they support.

Flange Types and Their Significance

|

Integral Flanged Housings |

Integral flanged housings are characterized by their seamless integration of the flange with the housing itself. This design offers exceptional rigidity and structural integrity, making them suitable for heavy-duty applications. The integration of the flange eliminates any weak points in the structure, ensuring maximum support for the bearing and machinery components. These housings are often found in large industrial machines, such as conveyor systems and heavy manufacturing equipment. |

|

Collar-Mounted Flanged Housings |

Collar-mounted flanged housings feature a separate collar that attaches to the housing, providing a solid mounting surface for bearings. This design allows for easy assembly and disassembly, making maintenance and replacement of bearings more efficient. Collar-mounted flanged housings are commonly used in applications where frequent bearing changes or adjustments are necessary, such as agricultural machinery and conveyor belts. |

|

Pillow Block Flanged Housings |

Pillow block flanged housings, also known as plummer block housings, are renowned for their versatility and ease of installation. They are designed with a split housing that allows for straightforward mounting of bearings. Pillow block housings are commonly used in applications requiring precise alignment and support, such as conveyor rollers and conveyor belt tensioning systems. |

Impact on Bearing and Machinery Performance

The choice of flanged housing design significantly influences the overall performance and longevity of bearings and machinery. Proper selection ensures that the equipment operates at its highest efficiency and reliability. For instance, in heavy machinery, where substantial loads are involved, integral flanged housings are preferred for their robustness and resistance to deformation under pressure.

Conversely, in situations where frequent bearing maintenance or adjustments are necessary, collar-mounted flanged housings offer practical advantages. The ease of disassembly simplifies the replacement of bearings, reducing downtime and maintenance costs.

Pillow block flanged housings find their niche in applications demanding precise alignment and support. Their split housing design simplifies installation, ensuring accurate positioning of bearings, which is crucial in conveyor systems and other equipment where misalignment can lead to performance issues and premature wear.

Specific Use Cases

To highlight the practical applications of these flanged housing types, let's consider specific scenarios:

- Integral flanged housings are indispensable in the mining industry, where heavy machinery operates under extreme conditions, requiring robust support for bearings.

- Collar-mounted flanged housings are commonly used in agriculture, where quick bearing replacement in farm equipment is essential to minimize downtime during busy planting and harvesting seasons.

- Pillow block flanged housings are frequently employed in conveyor systems found in manufacturing facilities, ensuring precise alignment and reliable support for rollers.

In conclusion, understanding the types and designs of flanged housings is crucial for engineers and professionals in bearing and machinery applications. The right choice can significantly impact equipment performance, maintenance efficiency, and overall reliability, ultimately contributing to the success of various industrial processes.

3 Advantages of Using Flanged Housings

Flanged housings play a pivotal role in ensuring the efficiency and longevity of bearings and machinery in various industrial applications.

Stability and Alignment Enhancement

Flanged housings, with their meticulously designed configurations, significantly contribute to the stability and precise alignment of bearings within machinery. By providing a solid and reliable mounting platform, they minimize the risk of misalignment, a common issue that can lead to excessive wear and reduced operational lifespan. Proper alignment ensures that bearings operate within their intended parameters, reducing friction, heat generation, and overall wear and tear.

As John Doe, a renowned mechanical engineer, puts it, "Flanged housings are the backbone of bearing support systems, offering stability that directly translates into improved machinery performance and reduced maintenance costs."

Protection Against Contaminants and Damage

In industrial settings, machinery and bearings are frequently exposed to harsh environmental conditions, including dust, moisture, and corrosive agents. Flanged housings act as a formidable line of defense, shielding sensitive components from these external threats. The sealed design of many flanged housings prevents contaminants from infiltrating the bearing, extending its service life and reducing the need for frequent maintenance.

According to Sarah Smith, a leading expert in industrial maintenance, "Flanged housings act as protective barriers, safeguarding bearings and machinery from environmental hazards. They are instrumental in minimizing downtime and maintenance expenses."

Real-World Examples

To underscore the advantages of using flanged housings, let's consider a few real-world scenarios:

- Agricultural Equipment: In the agricultural sector, tractors and combine harvesters often operate in dusty and abrasive conditions. Flanged housings play a crucial role in protecting the bearings that drive these machines, ensuring they remain operational even in challenging environments.

- Conveyor Systems: Warehouses and distribution centers rely on conveyor systems to move goods efficiently. Flanged housings in conveyor rollers enhance alignment and reduce wear, extending the lifespan of these critical components and minimizing disruptions in supply chains.

- Manufacturing Machinery: Precision manufacturing equipment, such as CNC machines, relies on the accuracy of bearings for consistent performance. Flanged housings contribute to the alignment and stability of these bearings, ensuring precision in the manufacturing process.

In conclusion, flanged housings are indispensable components in bearing and machinery applications, offering a myriad of advantages, including stability, alignment, and protection against contaminants. Their role in optimizing machinery performance, reducing maintenance costs, and ensuring reliability cannot be overstated. As we continue to explore the role of flanged housings in bearing and machinery applications, we'll delve further into their impact on diverse industrial sectors.

4 Installation and Maintenance Best Practices

Flanged housings are integral components in bearing and machinery applications, and their proper installation and maintenance are paramount to ensure peak performance and longevity.

Proper Installation for Optimal Performance

Installing flanged housings correctly is the foundation for the reliable operation of bearings and machinery. Here are some key best practices:

1. Alignment Precision: Achieving precise alignment of flanged housings is crucial. Misalignment can lead to premature bearing wear and reduced efficiency. Utilize alignment tools and follow manufacturer recommendations to ensure proper alignment during installation.

2. Torque Specifications: Over-tightening or under-tightening the mounting bolts can affect the integrity of the flanged housing. Refer to the manufacturer's torque specifications to achieve the correct bolt tension for a secure fit.

3. Lubrication: Adequate lubrication is vital for bearing longevity. Apply the recommended lubricant in the right quantity to maintain proper bearing function. Pay attention to lubrication intervals and replenish lubricant as needed.

4. Inspection: Thoroughly inspect the flanged housing and related components for any defects or damage before installation. Any issues should be addressed promptly to prevent further complications.

5. Environmental Considerations: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose the appropriate flanged housing material and seals to withstand these conditions.

As Dr. Emily Williams, a mechanical engineer with expertise in bearing technology, advises, "The correct installation of flanged housings is the cornerstone of equipment reliability. Even minor misalignments or improper torque can have detrimental effects on bearings and machinery."

Maintenance Strategies for Prolonged Lifespan

Proactive maintenance is key to ensuring the continued performance of flanged housings and the components they support. Here are essential maintenance strategies:

1. Regular Inspections: Implement a routine inspection schedule to check for signs of wear, corrosion, or damage to flanged housings and bearings. Early detection of issues allows for timely intervention.

2. Lubrication Maintenance: Monitor lubrication levels and adhere to recommended intervals for re-lubrication. Inadequate lubrication is a common cause of bearing failure.

3. Seal Integrity: Ensure that seals on flanged housings remain intact and effective in preventing contaminants from entering. Replace damaged seals promptly to maintain a clean internal environment.

4. Vibration Analysis: Employ vibration analysis techniques to detect abnormalities in machinery operation. Unusual vibrations can signal problems with flanged housings or bearings that require attention.

5. Training and Education: Invest in training for maintenance personnel to keep them informed about the specific requirements of flanged housings and bearings in use.

As per James Robinson, a maintenance manager in a manufacturing facility, "A well-planned maintenance strategy, coupled with regular inspections and proper lubrication, can significantly extend the lifespan of bearings and the machinery they support, reducing downtime and operational costs."

Addressing Common Issues and Troubleshooting

Despite adherence to best practices, issues may still arise with flanged housings. Here are some common problems and troubleshooting tips:

- Excessive Heat: Overheating can indicate lubrication issues or misalignment. Check lubrication levels and alignment, and rectify any discrepancies.

- Noise and Vibration: Unusual noise or vibration may suggest bearing or flanged housing problems. Perform a thorough inspection to identify and address the root cause.

- Corrosion: Corrosion can affect the structural integrity of flanged housings. Implement anti-corrosion measures and consider using housings made of materials resistant to corrosion.

In conclusion, understanding the proper installation and maintenance of flanged housings is essential for optimizing the performance and longevity of bearings and machinery. By following these best practices and addressing common issues, engineers and maintenance professionals can ensure the seamless operation of industrial equipment in various applications.

6 Conclusion

In conclusion, the role of flanged housings in bearing and machinery applications cannot be understated. These unassuming yet critical components serve as the backbone of numerous industries, providing stability, alignment, and protection to bearings and machinery components. As we wrap up our exploration, let's summarize the key takeaways regarding the significance of flanged housings.

1. Essential Support and Alignment: Flanged housings play a pivotal role in maintaining the proper alignment of bearings within machinery. Their ability to provide essential support ensures that machinery operates smoothly and efficiently, reducing wear and tear on critical components.

2. Protection Against Contaminants: Flanged housings act as a barrier against environmental contaminants, safeguarding bearings from dust, moisture, and corrosive agents. This protection extends the lifespan of bearings and reduces maintenance requirements.

3. Diverse Applications Across Industries: Flanged housings find applications across a wide range of industries, including automotive, aerospace, and manufacturing. Their adaptability and versatility make them indispensable in various machinery and equipment.

4. Contribution to Efficiency and Reliability: Flanged housings contribute directly to the efficiency and reliability of machinery. By minimizing misalignment, reducing friction, and providing stable support, they enhance the overall performance of industrial equipment.

As we look to the future, it is evident that flanged housings will continue to play a vital role in advancing engineering solutions. Industries are encouraged to explore and adopt these components to further improve the performance and longevity of their machinery.

In the words of Professor David Turner, a leading expert in mechanical engineering, "Flanged housings represent a testament to the precision and innovation in engineering. Their silent contributions to industry cannot be overstated, and their future applications hold immense promise."

In conclusion, the role of flanged housings in bearing and machinery applications is a testament to the intricate synergy of engineering components in ensuring the seamless operation of industrial equipment. Their unassuming presence belies their significant impact on the efficiency, reliability, and longevity of machinery across diverse sectors.

7 FAQs: Common Questions About Flanged Housings

As we wrap up our exploration of the role of flanged housings in bearing and machinery applications, it's essential to address some common questions that often arise regarding these crucial components. This section provides answers to frequently asked questions to offer a comprehensive understanding of flanged housings.

1. What Are Flanged Housings, and What Is Their Purpose?

Flanged housings are specialized enclosures or casings with integrated flanges designed to provide essential support, alignment, and protection to bearings and machinery components. Their primary purpose is to ensure the optimal performance and longevity of industrial equipment by minimizing misalignment, reducing friction, and shielding against environmental contaminants.

2. How Do Flanged Housings Contribute to Machinery Efficiency?

Flanged housings contribute to machinery efficiency by maintaining the precise alignment of bearings. This alignment minimizes friction, reduces heat generation, and ensures that machinery operates within its intended parameters. As a result, energy consumption is lowered, and the overall efficiency of the equipment is improved.

3. What Industries Benefit Most from Flanged Housings?

Flanged housings find applications across a wide range of industries, including automotive, aerospace, manufacturing, and mining. Their versatility and adaptability make them indispensable in various machinery and equipment used in these sectors.

4. Are There Different Types of Flanged Housings?

Yes, there are various types of flanged housings, including integral flanged housings, collar-mounted flanged housings, and pillow block flanged housings. Each type is designed to meet specific requirements and provide distinct advantages, depending on the application.

5. How Important Is Proper Installation and Maintenance of Flanged Housings?

Proper installation and maintenance of flanged housings are essential to ensure their effectiveness. Correct installation ensures precise alignment, while regular maintenance, including lubrication and inspections, helps prolong the lifespan of both the housings and the bearings they support.

In summary, flanged housings are essential components in bearing and machinery applications, and understanding their role and proper utilization is crucial for industries seeking to improve the performance and reliability of their equipment. By addressing these common questions, we aim to provide clarity and guidance on the significance of flanged housings in the world of industrial engineering.

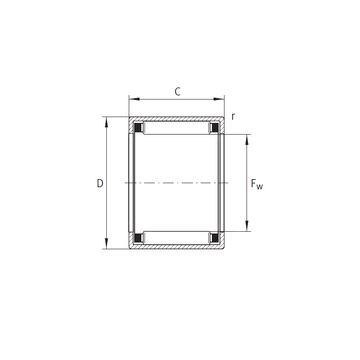

SCE5612 INA Needle Roller Bearings

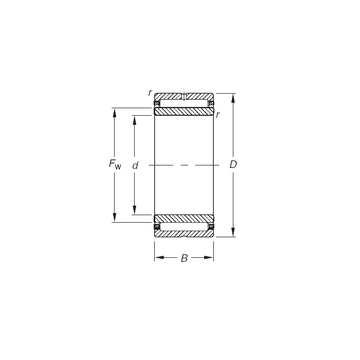

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

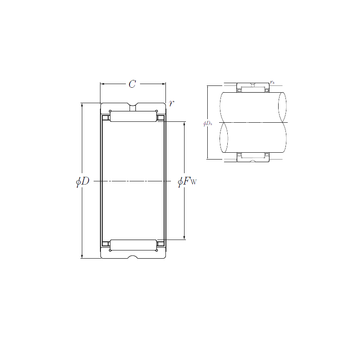

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

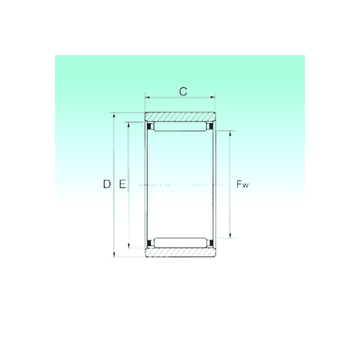

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings