Home> Company News> Mastering Precision: Super Precision Angular Contact Ball Bearings

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In the world of precision engineering, the quest for perfection and accuracy is an ongoing endeavor. Manufacturers and engineers are constantly seeking ways to enhance machinery performance and achieve the highest levels of precision. It is within this pursuit that super precision angular contact ball bearings emerge as vital components. we will delve into the world of these remarkable bearings, exploring their fundamental principles, applications in various industries, and the significant advantages they offer in the realm of precision engineering.

Super Precision Angular Contact Ball Bearings: The Pinnacle of Precision

At the heart of many precision mechanical systems lie super precision angular contact ball bearings. These specialized bearings play a crucial role in ensuring the highest levels of accuracy, reliability, and performance. But what exactly are super precision angular contact ball bearings, and why are they considered the pinnacle of precision in the engineering world?

Defining Super Precision Angular Contact Ball Bearings

Super precision angular contact ball bearings are a subset of the broader category of ball bearings, designed with an emphasis on precision and accuracy. They are engineered to provide optimal control over axial and radial loads, making them ideal for applications where precise motion control is essential. These bearings are meticulously manufactured to exacting standards, ensuring minimal friction and superior durability.

The Role of Super Precision Bearings

These bearings are not just another cog in the machinery; they are the linchpin of precision engineering. Super precision angular contact ball bearings are designed to accommodate both radial and axial loads in a specific way, allowing for precise control of the rotation angle, making them particularly valuable in applications where accuracy is paramount.

Overview of the Article

In this comprehensive article, we will explore every facet of super precision angular contact ball bearings. We will begin by delving into the working principles that make these bearings stand out in the world of precision engineering. From there, we will journey into the diverse applications and industries that rely on these bearings, highlighting their versatility and adaptability. As we move forward, we will enumerate the numerous benefits of incorporating super precision bearings into machinery, emphasizing how they elevate performance, reliability, and maintenance. We will also discuss the critical factors to consider when selecting and installing these bearings, ensuring that they function optimally. Moreover, we will delve into maintenance and calibration guidelines to extend the lifespan of these precision components and troubleshoot common issues effectively. Lastly, we will cast our gaze toward the future, exploring the latest trends and innovations in super precision angular contact ball bearings, showcasing how emerging technologies are shaping the landscape of precision engineering.

Working Principles of Super Precision Angular Contact Ball Bearings

To truly master precision in the realm of machinery and engineering, it's essential to understand the fundamental principles behind super precision angular contact ball bearings. These remarkable bearings play a pivotal role in achieving the highest levels of accuracy, reliability, and performance in various applications. we will delve into the working principles that set super precision bearings apart from the rest, differentiating them from radial contact ball bearings and shedding light on the design features that contribute to their precision.

Explaining the Fundamental Principles

Super precision angular contact ball bearings are a specialized type of ball bearing meticulously engineered to provide optimal control over both axial and radial loads. This unique design allows them to excel in applications where precise motion control is crucial. At the core of their operation lies the concept of contact angles.

These bearings feature an angular contact design, meaning the inner and outer raceways are designed to meet at an angle. This configuration enables them to carry both axial (thrust) and radial (perpendicular) loads simultaneously. It's this precise arrangement that allows super precision bearings to excel in situations where traditional radial contact bearings may fall short.

Differentiating Angular Contact from Radial Contact Ball Bearings

One of the key distinctions between super precision angular contact ball bearings and their radial contact counterparts is the orientation of the bearing races. In radial contact bearings, the inner and outer races are aligned parallel to each other, resulting in primarily radial load-carrying capacity. This design is suitable for applications where primarily vertical or radial forces are encountered.

On the other hand, super precision angular contact ball bearings are designed with the races at an angle to each other. This angular configuration enables them to handle a combination of axial and radial loads. The contact angle between the races determines the bearing's ability to handle axial loads. Greater contact angles equate to higher axial load-carrying capacity, making them ideal for situations where both thrust and radial forces must be managed with precision.

Highlighting Design Features for Precision

Achieving super precision requires meticulous design and manufacturing. These bearings are crafted to exacting standards to minimize friction, reduce wear, and ensure exceptional durability. They often incorporate precision-made ball bearings, cages, and raceways, all designed with the utmost precision.

Furthermore, the materials used in super precision angular contact ball bearings are of the highest quality, often featuring specialized alloys and heat treatments. This attention to detail in material selection and manufacturing processes contributes to their outstanding precision.

In conclusion, mastering precision with super precision angular contact ball bearings hinges on understanding their unique working principles. The angular contact design, differentiation from radial contact bearings, and meticulous attention to design features all play a crucial role in achieving the pinnacle of precision engineering. These principles form the foundation upon which super precision bearings enhance machinery performance and accuracy.

Applications and Industries

Super precision angular contact ball bearings, with their unparalleled precision and performance, find extensive applications across a diverse range of industries. These remarkable bearings play a pivotal role in elevating precision, control, and reliability in various mechanical systems. we will explore the wide array of industries and applications that heavily rely on super precision angular contact ball bearings, highlighting real-world examples of their impact and the significant advantages they offer to different sectors.

Diverse Range of Industries

|

Aerospace Industry |

In the aerospace sector, where precision is non-negotiable, super precision angular contact ball bearings are employed in critical components such as jet engines, landing gear systems, and guidance systems. Their ability to withstand high-speed rotation, extreme temperatures, and heavy loads is indispensable for the safety and efficiency of air travel. |

|

Medical Equipment |

Precision in medical equipment is paramount. These bearings are used in advanced medical devices like CT scanners, MRI machines, and surgical robots. Their smooth operation ensures accurate diagnosis and minimally invasive procedures. |

|

Machine Tool Manufacturing |

Precision machining demands super precision bearings. Industries that manufacture machine tools for cutting, shaping, and milling rely on these bearings to ensure the utmost accuracy and surface finish in the final product. |

|

Automotive Sector |

Modern vehicles are equipped with various sensors and control systems that require precise motion control. Super precision angular contact ball bearings find applications in steering systems, transmissions, and electric power steering units, contributing to enhanced vehicle control and safety. |

|

Robotics and Automation |

Robots and automated systems require high levels of accuracy and repeatability. Super precision bearings are integral to robotic arms, joints, and end-effectors, allowing for precise and controlled movements. |

Real-World Examples

Let's delve into real-world examples to illustrate the impact of super precision angular contact ball bearings:

- Aerospace: Consider a commercial airliner's jet engine. Super precision bearings in the engine's rotating components ensure efficient power generation, reduced fuel consumption, and reliable performance, all while withstanding extreme temperature variations and mechanical stress.

- Medical Equipment: In a cutting-edge MRI machine, super precision bearings facilitate the smooth rotation of the imaging gantry. This precision is crucial for producing high-resolution medical images, aiding in accurate diagnoses.

- Machine Tool Manufacturing: Precision machining relies on super precision angular contact ball bearings in spindle units. These bearings enable the machine to precisely cut and shape materials, resulting in high-quality finished products.

- Automotive Sector: In an electric power steering system, super precision bearings allow for precise and responsive steering control. This not only enhances driving comfort but also contributes to safety by assisting with stability and control.

- Robotics and Automation: In an industrial robot's articulated arm, super precision bearings ensure precise movement and positioning. This accuracy is essential for tasks such as welding, assembly, and pick-and-place operations.

Advantages in Different Sectors

The advantages of using super precision angular contact ball bearings in various sectors are evident. They provide:

- Enhanced Precision: These bearings offer exceptional accuracy, enabling machinery and systems to perform tasks with the utmost precision.

- Improved Reliability: Their robust design and materials contribute to reliability and longevity, reducing maintenance and downtime.

- Efficient Performance: Super precision bearings minimize friction and energy loss, optimizing the overall efficiency of mechanical systems.

- Controlled Motion: Industries and applications that require controlled and predictable motion benefit from the precision of these bearings.

In conclusion, super precision angular contact ball bearings are at the heart of mastering precision in numerous industries and applications. Their diverse range of applications, real-world examples, and the advantages they bring to different sectors underscore their indispensable role in achieving unparalleled levels of precision, control, and reliability.

Benefits of Super Precision Angular Contact Ball Bearings

Super precision angular contact ball bearings are an engineering marvel that brings a plethora of benefits to various industries and applications. we will delve into the advantages of incorporating these remarkable bearings, highlighting how they significantly improve machinery performance, enhance reliability, and streamline maintenance processes. Additionally, we'll explore the cost-saving implications of proactive maintenance and precision engineering when utilizing super precision angular contact ball bearings.

Advantages of Super Precision Bearings

Exceptional Precision: As the name suggests, super precision angular contact ball bearings are designed to provide unparalleled levels of precision. They enable machinery to perform tasks with utmost accuracy, crucial in applications where even the slightest deviation can lead to inefficiency or errors.

Enhanced Reliability: The robust design and high-quality materials used in super precision bearings contribute to their exceptional reliability. They are engineered to withstand demanding conditions and offer extended operational lifespans, reducing the need for frequent replacements or repairs.

Optimized Performance: These bearings minimize friction and energy loss within mechanical systems. As a result, machinery operates more efficiently, consuming less power and reducing operating costs. Moreover, the reduction in friction leads to less heat generation, further extending the lifespan of critical components.

Reduced Downtime: Super precision bearings, with their durability and low maintenance requirements, contribute to reduced downtime in industrial settings. This translates to higher productivity and cost savings, especially in industries where continuous operation is paramount.

Precise Control: Industries and applications that demand controlled and predictable motion benefit significantly from the precision of these bearings. Whether in robotics, machine tools, or automated systems, super precision bearings ensure precise and reliable movements.

Cost Savings through Proactive Maintenance: Regular maintenance is essential to maximize the benefits of super precision bearings. However, the proactive approach to maintenance, which includes timely inspections, lubrication, and component replacements, leads to significant cost savings in the long run. Preventing breakdowns and unexpected failures not only reduces repair expenses but also minimizes production losses.

Precision Engineering: Super precision bearings are often integrated into precision engineering systems. They play a critical role in achieving the desired levels of accuracy and repeatability in manufacturing processes. This precision engineering results in higher-quality products and lower production costs.

Conclusion

In conclusion, super precision angular contact ball bearings are a cornerstone of mastering precision in machinery and engineering. Their exceptional precision, enhanced reliability, optimized performance, and ability to reduce downtime make them indispensable in various industries. Furthermore, proactive maintenance practices and precision engineering ensure that these bearings deliver long-term cost savings and uphold the highest standards of precision and control. Incorporating super precision bearings into your machinery can lead to improved productivity, reduced operational costs, and superior performance, ultimately propelling your precision engineering to new heights.

Selection and Installation of Super Precision Angular Contact Ball Bearings

Selecting and installing super precision angular contact ball bearings is a crucial process in precision engineering. These bearings play a pivotal role in achieving superior accuracy and control in machinery. we will explore the key factors to consider when choosing the right bearings for your specific machinery and delve into the best practices for their proper installation. Additionally, we'll emphasize the importance of compatibility and calibration in precision engineering applications.

Factors to Consider in Selection

Load Capacity: The first and foremost consideration when selecting super precision angular contact ball bearings is their load-carrying capacity. Determine the maximum load that the bearing will be subjected to during operation, and choose bearings with a capacity well above this requirement to ensure safety and longevity.

Speed Ratings: Different applications require varying levels of rotational speed. Be sure to select bearings with speed ratings that exceed the operational speed of your machinery. This will prevent overheating and premature wear due to excessive RPM.

Accuracy Requirements: Precision engineering demands high levels of accuracy. Assess the precision requirements of your application and choose bearings that offer the necessary level of precision. Super precision bearings are available in different accuracy classes, such as P4, P2, or even higher.

Lubrication: Proper lubrication is essential for bearing longevity and performance. Consider the lubrication method (grease or oil) and the lubrication interval needed for your machinery. Some super precision bearings come pre-lubricated, while others require initial lubrication during installation.

Sealing and Shielding: Depending on the operating environment, you may need to choose bearings with appropriate sealing or shielding options. Seals help prevent contamination and retain lubrication, while shields offer protection against light debris and particles.

Installation Best Practices

Cleanliness: Maintaining a clean working environment during installation is crucial. Contaminants such as dirt and dust can compromise bearing performance. Clean all components thoroughly before assembly.

Proper Handling: Handle super precision angular contact ball bearings with care. Avoid dropping or mishandling them, as this can lead to damage or premature wear. Always use clean gloves to prevent skin oils from contaminating the bearings.

Mounting: Ensure that the bearings are mounted accurately and securely. Use appropriate tools and follow manufacturer guidelines for fit tolerances. Over-tightening or improper fitting can lead to damage.

Alignment: Proper alignment of bearings is vital for precision engineering applications. Misalignment can cause excessive load, friction, and premature wear. Use precision alignment tools to achieve the desired alignment.

Compatibility and Calibration

Super precision angular contact ball bearings should be compatible with the overall machinery design. Ensure that the bearings align with the intended performance and accuracy goals of your machinery. Additionally, calibration of bearings and related components, such as shafts and housings, is essential to achieve optimal precision and control.

In conclusion, the selection and installation of super precision angular contact ball bearings are critical steps in mastering precision in machinery. By considering factors like load capacity, speed ratings, accuracy requirements, lubrication, and proper handling, you can ensure that the chosen bearings will meet the demands of your precision engineering applications. Proper installation practices, including cleanliness, mounting, and alignment, further contribute to the longevity and performance of these bearings. Lastly, compatibility and calibration play pivotal roles in achieving the desired precision and control in machinery, making super precision bearings an invaluable component in precision engineering.

Maintenance and Calibration of Super Precision Angular Contact Ball Bearings

Maintaining and calibrating super precision angular contact ball bearings is essential to ensure their longevity and sustained precision in machinery. we will delve into the guidelines for effectively maintaining and calibrating these high-precision bearings. We will also highlight the critical role that regular maintenance plays in prolonging the lifespan of super precision bearings and provide insights into troubleshooting common issues to maintain precision in machinery.

Maintenance Guidelines

Regular Inspection: Implement a routine inspection schedule to check for any signs of wear, damage, or contamination. Regular visual inspections can help detect issues early on.

Lubrication: Lubrication is crucial for reducing friction and maintaining precision. Follow the manufacturer's recommendations for lubrication intervals and use the appropriate lubricants. Ensure that the lubrication method is consistent with the bearing's design.

Cleaning: Keep the bearings and surrounding components clean. Any contaminants, such as dust or debris, can compromise precision. Use clean tools and ensure a dust-free environment during maintenance.

Temperature Control: Maintain stable operating temperatures. Excessive heat can cause thermal expansion, affecting bearing clearance and accuracy. Adequate cooling or temperature control measures should be in place.

Alignment Checks: Periodically check and adjust the alignment of the bearings to ensure they remain in the desired position. Misalignment can lead to premature wear and reduced precision.

Calibration Procedures

|

Calibration Equipment |

Invest in precision calibration equipment suitable for super precision angular contact ball bearings. This includes tools for measuring radial clearance, axial preload, and runout. |

|

Radial Clearance Calibration |

Precise radial clearance is critical for super precision bearings. Use gauges and instruments to measure and adjust radial clearance as needed. |

|

Axial Preload Calibration |

Proper axial preload ensures optimal contact between bearing elements. Calibration tools help set the correct axial preload according to manufacturer specifications. |

|

Runout Measurement |

Measuring runout is essential for assessing bearing accuracy. Calibrate the bearings to minimize runout and achieve the desired precision. |

Role of Regular Maintenance

Regular maintenance is more than just a preventative measure; it is a fundamental aspect of maximizing the lifespan and performance of super precision angular contact ball bearings. Proper maintenance:

- Prolongs Lifespan: Timely inspections and lubrication help prevent premature wear, extending the lifespan of the bearings.

- Sustains Precision: Well-maintained bearings continue to perform with the high degree of precision they were designed for.

- Minimizes Downtime: Scheduled maintenance reduces the risk of unexpected breakdowns, minimizing machinery downtime.

Troubleshooting Common Issues

Excessive Heat: If the bearings are running hot, it may indicate improper lubrication or misalignment. Address the root cause to prevent bearing damage.

Unusual Noise: Unusual noises during operation can signal issues with the bearings. Investigate and resolve any abnormal sounds promptly.

Vibration: Excessive vibration is often related to misalignment, improper preload, or wear. Check and adjust as necessary.

In conclusion, maintaining and calibrating super precision angular contact ball bearings are essential practices for achieving and sustaining precision in machinery. By following maintenance guidelines, investing in calibration equipment, and addressing common issues proactively, you can ensure that these high-precision bearings continue to meet the demands of precision engineering applications. Regular maintenance not only prolongs the lifespan of the bearings but also contributes to the overall efficiency and reliability of machinery.

Future Trends and Innovations in Super Precision Angular Contact Ball Bearings

The field of super precision angular contact ball bearings is continually evolving, driven by advancements in technology and the ever-increasing demand for higher precision and performance in various industries. we will delve into the future trends and innovations that are shaping the landscape of super precision bearings, exploring the latest developments and their potential implications for precision engineering applications.

Exploring the Latest Developments

Advanced Materials: Future trends in super precision bearings are expected to focus on the development and integration of advanced materials. Innovations in ceramic materials, for instance, are enabling bearings to withstand higher speeds and temperatures while maintaining their precision.

Miniaturization: As industries demand smaller, more compact machinery, super precision bearings are likely to undergo further miniaturization. This trend will cater to applications where space constraints are paramount.

Integrated Sensing: The integration of sensors within super precision angular contact ball bearings is an emerging trend. These sensors can monitor bearing health, temperature, and performance in real-time, allowing for predictive maintenance and improved reliability.

Smart Lubrication: Future bearings may incorporate smart lubrication systems that adjust lubrication levels based on real-time conditions. This can extend bearing life and optimize performance.

Emerging Technologies Shaping the Future

Industry 4.0 and IoT Integration: The integration of super precision bearings with Industry 4.0 and the Internet of Things (IoT) is set to revolutionize manufacturing processes. These smart bearings can communicate data to centralized systems, facilitating predictive maintenance and production optimization.

Nanotechnology: Nanotechnology is expected to play a significant role in the future of super precision bearings. Nanoscale engineering can enhance bearing surfaces, reduce friction, and improve overall performance.

3D Printing: Additive manufacturing, or 3D printing, is enabling the rapid prototyping and customization of super precision bearings. This technology can lead to cost-effective solutions tailored to specific applications.

Potential Advancements and Industry Implications

Higher Precision Levels: Future super precision bearings may achieve even higher levels of precision, making them suitable for applications that demand extreme accuracy, such as medical devices and aerospace equipment.

Energy Efficiency: The development of energy-efficient bearings will have a significant impact on industries striving to reduce energy consumption. Bearings that minimize friction and optimize performance contribute to greener manufacturing processes.

Diverse Industry Applications: As super precision bearings evolve, their applications will diversify across industries, including robotics, semiconductor manufacturing, healthcare, and renewable energy. This broader scope will lead to more versatile and adaptable bearings.

In conclusion, the future of super precision angular contact ball bearings holds exciting possibilities. Advanced materials, miniaturization, integrated sensing, and smart lubrication are just a few of the trends shaping the industry. Emerging technologies like IoT integration, nanotechnology, and 3D printing promise to take precision engineering to new heights. With higher precision levels, energy efficiency, and diverse applications on the horizon, super precision bearings are set to master precision in a wide range of industries, revolutionizing the way machinery operates and advancing the field of precision engineering.

Conclusion: Mastering Precision with Super Precision Angular Contact Ball Bearings

In conclusion, our journey through the world of super precision angular contact ball bearings has shed light on the critical role these precision-engineered components play in enhancing machinery performance and accuracy. As we summarize the key takeaways from our exploration, it becomes evident that mastering precision is not only possible but also essential in various industries that rely on precision engineering.

Enhancing Machinery Performance and Accuracy

Throughout this article, we've highlighted the fundamental principles, applications, and benefits of super precision angular contact ball bearings. These bearings, designed with precision engineering in mind, offer a level of accuracy and performance that is unparalleled in the world of mechanical systems. Their ability to handle high speeds, heavy loads, and complex movements while maintaining precision is a testament to their engineering excellence.

Super precision bearings find applications in industries where precision is not just a preference but a necessity. Whether it's the aerospace sector, medical equipment manufacturing, semiconductor fabrication, or any other field that demands extreme accuracy, these bearings have proven their worth. By minimizing friction, reducing heat generation, and optimizing machinery dynamics, they contribute significantly to overall machinery efficiency.

Continued Exploration and Adoption

As technology continues to advance and industries evolve, the importance of super precision angular contact ball bearings will only grow. Their integration with emerging technologies such as IoT, nanotechnology, and 3D printing is reshaping the landscape of precision engineering. The potential for higher precision levels, energy efficiency, and diverse applications is vast, promising innovation and growth in the field.

In conclusion, super precision bearings are the linchpin of precision engineering, enabling machinery to achieve levels of accuracy and performance that were once thought unattainable. They are the unsung heroes behind the scenes, ensuring that our modern world operates with the utmost precision and efficiency. As we move forward, it is imperative that industries continue to explore and adopt these remarkable components to master precision in their mechanical systems.

With this, we wrap up our exploration of super precision angular contact ball bearings, hoping to inspire further research, innovation, and adoption of these incredible components. Mastering precision is not just a goal; it's a journey, and super precision bearings are our trusted companions on this path to engineering excellence.

FAQs: Common Questions About Super Precision Angular Contact Ball Bearings

we'll address some of the frequently asked questions (FAQs) about super precision angular contact ball bearings. These precision-engineered components play a crucial role in various industries, and understanding their characteristics and applications is essential. Let's delve into some common queries related to super precision bearings:

What Are Super Precision Angular Contact Ball Bearings?

Super precision angular contact ball bearings are specialized bearings designed to provide extremely high accuracy and precision in machinery. They are engineered to handle both radial and axial loads while maintaining precise contact angles, making them ideal for applications requiring precision and tight tolerances.

How Do Super Precision Bearings Differ from Standard Bearings?

The primary difference lies in precision. Super precision bearings are manufactured to much tighter tolerances, ensuring minimal deviation from ideal geometry. This results in reduced internal clearances, better load distribution, and improved rotational accuracy compared to standard bearings.

What Industries Benefit from Super Precision Bearings?

A wide range of industries benefits from super precision angular contact ball bearings, including aerospace, medical devices, semiconductor manufacturing, robotics, and machine tools. Any application demanding high-speed rotation, precise positioning, and minimal vibration can benefit from these bearings.

How Do Super Precision Bearings Enhance Accuracy?

These bearings excel in maintaining precise contact angles between the inner and outer races. This controlled contact minimizes deflection and reduces axial play, resulting in superior machinery accuracy, especially in high-precision tasks such as CNC machining and optical equipment.

Can Super Precision Bearings Handle High-Speed Applications?

Absolutely. Super precision bearings are designed for high-speed applications, and their inherent precision and reduced friction help in minimizing heat generation, thereby extending bearing life and ensuring consistent performance at elevated speeds.

Are Super Precision Bearings Suitable for Heavy Loads?

Yes, they are. Despite their precision, super precision angular contact ball bearings can handle both high-speed rotation and heavy loads. Their superior load-carrying capacity is a result of advanced engineering and material selection.

What Maintenance Practices Are Recommended for Super Precision Bearings?

Regular maintenance is crucial to ensure the longevity and performance of super precision bearings. This includes proper lubrication, monitoring for wear, and ensuring that the bearings are kept clean and free from contaminants. It's also advisable to follow manufacturer guidelines for maintenance intervals.

How Do I Select the Right Super Precision Bearing for My Application?

Selecting the appropriate super precision bearing involves considering factors such as load type, speed, precision requirements, and environmental conditions. Consulting with a bearing specialist or referring to manufacturer guidelines is often recommended to make an informed choice.

What Innovations Are Shaping the Future of Super Precision Bearings?

The future of super precision bearings is exciting, with innovations such as ceramic materials, smart bearings with integrated sensors, and nanotechnology contributing to enhanced performance and precision. These advancements are expected to further broaden the applications and capabilities of super precision angular contact ball bearings.

Where Can I Source High-Quality Super Precision Bearings?

High-quality super precision angular contact ball bearings are available from reputable bearing manufacturers and distributors. It's essential to choose a trusted supplier known for producing precision-engineered bearings and providing excellent customer support.

By addressing these frequently asked questions, we hope to provide you with a comprehensive understanding of super precision angular contact ball bearings and their significance in precision engineering applications. These bearings are at the forefront of achieving and mastering precision in various industries, ensuring the highest levels of accuracy and performance in mechanical systems.

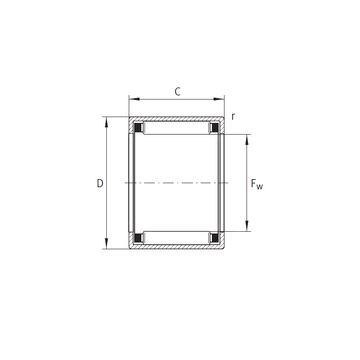

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

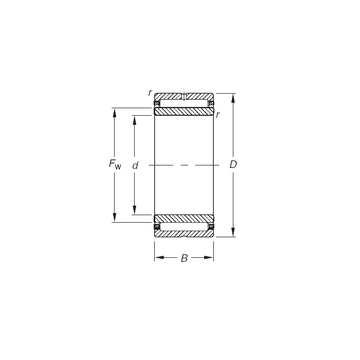

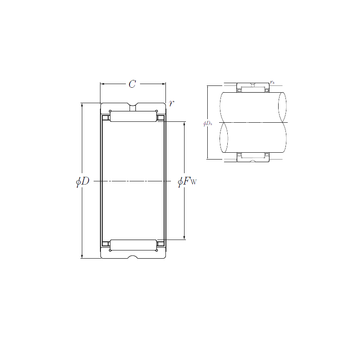

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

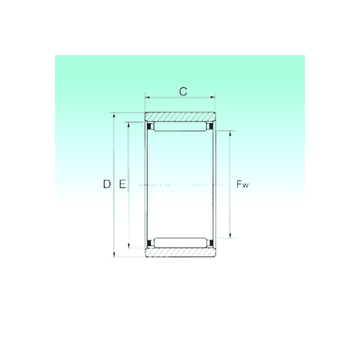

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings