Home> Company News> Precision in Motion: The Advantages of Self-Aligning Ball Bearings

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In the world of industrial applications, precision in motion is a paramount consideration. The efficiency and reliability of machinery depend significantly on the components that enable precise motion control. One such crucial component that plays a pivotal role in achieving precision is the self-aligning ball bearing. This article explores the advantages and benefits of self-aligning ball bearings, shedding light on their importance in various industries and applications.

Self-aligning ball bearings are precision-engineered components designed to allow for angular misalignment between the shaft and the housing. This unique characteristic sets them apart from traditional ball bearings and opens up a realm of possibilities for achieving precision in motion. In this article, we will delve into the inner workings of self-aligning ball bearings, their advantages over other bearing types, and their diverse applications across industries.

Self-Aligning Ball Bearings: Understanding the Basics

In the realm of precision motion control, self-aligning ball bearings play a pivotal role. To appreciate their advantages fully, it's essential to understand the fundamental principles behind these remarkable components. In this section, we will delve into the basics of self-aligning ball bearings, shedding light on what they are, how they function, and why self-alignment is a crucial attribute in the world of industrial machinery.

What are Self-Aligning Ball Bearings?

Self-aligning ball bearings, often referred to simply as self-aligning bearings, are a specialized type of ball bearing designed to accommodate angular misalignment between the shaft and the housing. Unlike traditional ball bearings, which require precise alignment for optimal performance, self-aligning ball bearings can operate efficiently even when there is a degree of misalignment. This unique feature makes them ideal for applications where shaft deflection, mounting errors, or other alignment challenges may arise.

Key Design Features

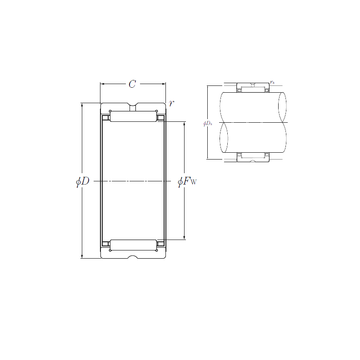

Self-aligning ball bearings incorporate several key design features that enable them to self-adjust to misalignment:

|

Double-Row Design |

Self-aligning ball bearings typically consist of two rows of balls, one inner ring, and one outer ring. This double-row configuration provides increased load-carrying capacity and greater stability. |

|

Spherical Outer Ring Raceway |

The outer ring of a self-aligning ball bearing is designed with a spherical raceway, allowing it to pivot and accommodate angular misalignment. |

|

Cage Design |

A cage or separator between the balls ensures proper ball spacing and alignment, contributing to smooth operation and reduced friction. |

|

Optimized Internal Geometry |

Precision engineering ensures the right balance between radial and axial loads, making self-aligning ball bearings versatile in various applications.

|

How Self-Aligning Ball Bearings Work

The operation of self-aligning ball bearings revolves around their ability to self-adjust to misalignment. When angular misalignment occurs between the shaft and the housing, the spherical raceway of the outer ring allows the bearing to align itself, minimizing stress and friction. This self-aligning capability enhances the bearing's lifespan and performance, making it a reliable choice for demanding industrial applications.

Importance of Self-Alignment in Industrial Machinery

In industrial machinery, precise motion control is essential for efficiency and reliability. However, achieving and maintaining perfect alignment in real-world applications can be challenging. Factors such as shaft deflection, thermal expansion, and mounting errors can introduce misalignment, leading to premature bearing wear and reduced machinery performance.

Self-aligning ball bearings address these challenges by offering a solution that can adapt to misalignment. They provide several advantages, including:

- Reduced Maintenance: Self-aligning ball bearings require less frequent maintenance and adjustment, resulting in reduced downtime.

- Extended Lifespan: The ability to self-align reduces stress on the bearing, leading to a longer operational life.

- Improved Efficiency: By accommodating misalignment, these bearings contribute to smoother operation and improved machinery efficiency.

In summary, self-aligning ball bearings serve as a cornerstone of precision in motion by offering the flexibility to adapt to real-world conditions. Their unique design features and self-aligning capability make them indispensable in various industrial applications, ensuring machinery operates efficiently and reliably, even in challenging environments.

Advantages and Benefits

Self-aligning ball bearings have become a cornerstone in precision motion control and various industrial applications. In this section, we will delve into the significant advantages and benefits of utilizing self-aligning ball bearings, highlighting their invaluable contribution to enhancing machinery performance and reliability. Additionally, we will provide a comparative analysis with other bearing types to underscore the distinct advantages that self-aligning ball bearings offer.

Enhancing Machinery Performance

One of the primary advantages of self-aligning ball bearings is their ability to enhance machinery performance in various ways. Let's explore how they achieve this:

|

Misalignment Compensation |

Self-aligning ball bearings excel in compensating for angular misalignment between the shaft and the housing. Unlike rigid bearings that demand meticulous alignment, self-aligning bearings can accommodate deviations, ensuring smoother operation. This ability significantly reduces wear and tear on both the bearing itself and surrounding components. |

|

Reduced Friction and Heat Generation |

The self-aligning capability of these bearings translates into reduced friction and heat generation during operation. Lower friction levels result in less energy loss and decreased wear on bearing surfaces. As a result, machinery operates more efficiently, which can lead to energy savings and extended component life. |

|

Improved Load Distribution |

Self-aligning ball bearings are designed to distribute both radial and axial loads effectively. Their optimized internal geometry ensures that loads are evenly distributed, reducing stress on individual components. This balanced load distribution results in improved machinery reliability and longevity. |

Contributing to Reliability

Reliability is a critical factor in industrial machinery, and self-aligning ball bearings play a pivotal role in ensuring it. Here's how these bearings contribute to increased reliability:

Extended Service Life

The ability to self-align reduces the risk of premature bearing failure due to misalignment. This feature extends the service life of self-aligning ball bearings, reducing the frequency of replacements and associated downtime.

Lower Maintenance Requirements

Self-aligning ball bearings demand less frequent maintenance compared to rigid bearings. Their self-adjusting nature means that they can continue to operate effectively even when minor misalignments occur. Reduced maintenance requirements translate into cost savings and increased uptime.

Comparative Analysis

To highlight the advantages of self-aligning ball bearings further, let's briefly compare them to other bearing types:

- Rigid Bearings

Unlike rigid bearings, which require precise alignment, self-aligning ball bearings can operate efficiently even with moderate misalignment. This key difference minimizes the need for meticulous setup and ongoing adjustments, making them a more versatile and maintenance-friendly option.

- Spherical Roller Bearings

While spherical roller bearings share some self-aligning characteristics, they are typically bulkier and costlier. Self-aligning ball bearings offer a more compact and cost-effective solution without compromising performance.

In conclusion, self-aligning ball bearings offer a myriad of advantages that contribute to enhanced machinery performance and reliability. Their ability to compensate for misalignment, reduce friction and heat generation, and distribute loads evenly make them a valuable choice in various industrial applications. When compared to other bearing types, self-aligning ball bearings stand out as a versatile, efficient, and cost-effective solution.

Applications Across Industries

Self-aligning ball bearings are versatile components that have found applications across various industries, revolutionizing precision and motion control. In this section, we will explore the wide range of industries where self-aligning ball bearings play a crucial role. We'll delve into specific use cases and examples within automotive, manufacturing, and other sectors, emphasizing how these bearings contribute to enhancing precision and motion control.

Automotive Industry

The automotive industry is one of the primary sectors where self-aligning ball bearings have made significant inroads. Their versatile nature and precision performance make them invaluable in various automotive applications:

Steering Systems

Self-aligning ball bearings are commonly employed in steering systems, where precise control and alignment are essential for vehicle safety. These bearings ensure smooth and reliable steering performance, contributing to overall road safety.

Wheel Hubs

In wheel hub assemblies, self-aligning ball bearings support radial and axial loads, providing the required precision and durability. Their ability to compensate for misalignment due to road conditions ensures a comfortable and safe driving experience.

Transmission Systems

Transmission systems require precise motion control, and self-aligning ball bearings excel in this regard. They enable smooth gear shifting and power transmission, enhancing the efficiency and performance of automotive transmissions.

Manufacturing Sector

The manufacturing sector relies heavily on precision machinery and equipment, making self-aligning ball bearings a natural fit for various applications:

Conveyor Systems

Conveyor systems in manufacturing facilities often employ self-aligning ball bearings to ensure the smooth movement of materials. These bearings accommodate misalignment, reducing the risk of conveyor jams and downtime.

Machine Tools

Machine tools demand high precision and accuracy. Self-aligning ball bearings are commonly used in spindle and rotary tables of machine tools, contributing to the precision and reliability of machining operations.

Other Industries

Apart from automotive and manufacturing, self-aligning ball bearings find applications in several other industries, including:

- Agriculture

In agricultural machinery such as tractors and combines, these bearings help maintain precise alignment in various components, enhancing equipment performance.

- Mining

In mining equipment, where heavy loads and harsh conditions are prevalent, self-aligning ball bearings provide the necessary reliability and durability.

- Aerospace

Self-aligning ball bearings are also used in aerospace applications, contributing to the precision and safety of flight control systems.

In conclusion, self-aligning ball bearings have made significant contributions to enhancing precision and motion control across a wide spectrum of industries. Their ability to accommodate misalignment, reduce friction, and ensure reliable performance has solidified their position as a key component in the pursuit of precision in motion. From automotive steering systems to manufacturing conveyor belts, these bearings play an essential role in ensuring the efficient operation of critical machinery and equipment.

Selecting the Right Bearing

Selecting the right type of bearing is crucial to ensure optimal performance in industrial applications. When it comes to self-aligning ball bearings, several factors need to be considered to make the best choice. In this section, we will discuss the key considerations for selecting self-aligning ball bearings, including load magnitude, speed, lubrication, and environmental conditions. We will also emphasize the importance of consulting experts or manufacturers to make an informed decision.

Load Magnitude

The magnitude of the load that a bearing will be subjected to is a fundamental consideration. Self-aligning ball bearings are known for their ability to accommodate both radial and axial loads. However, the specific load ratings for a particular bearing must be matched to the expected loads in the application. Calculating the load based on factors such as equipment weight, rotational speed, and dynamic forces is essential.

Speed

The rotational speed of the bearing is another critical factor in bearing selection. Self-aligning ball bearings are suitable for moderate to high-speed applications. However, it's essential to determine the required speed rating to avoid issues such as overheating or premature wear. Manufacturers provide speed ratings for their bearings, allowing engineers to make informed choices.

Lubrication

Proper lubrication is vital to the longevity and performance of self-aligning ball bearings. The choice of lubricant and its application method must be carefully considered. Factors such as operating temperature, speed, and load conditions influence the selection of the most suitable lubricant. It's important to follow manufacturer recommendations and maintenance schedules to ensure optimal lubrication.

Environmental Conditions

The operating environment plays a significant role in bearing selection. Factors like temperature extremes, exposure to contaminants, and the presence of moisture can impact bearing performance. Self-aligning ball bearings are designed to be resilient in various environments, but it's crucial to assess the specific conditions of the application and choose bearings with appropriate seals or shields to prevent contamination.

Consulting Experts or Manufacturers

In complex applications or situations where the optimal bearing choice is uncertain, consulting experts or manufacturers is highly advisable. These professionals have extensive knowledge and experience in bearing selection and can provide valuable guidance. They can analyze the application's requirements, perform calculations, and recommend the most suitable self-aligning ball bearings for the job.

In conclusion, selecting the right self-aligning ball bearings is a critical step in ensuring the precision and efficiency of industrial machinery. Factors such as load magnitude, speed, lubrication, and environmental conditions must be carefully evaluated. Consulting experts or manufacturers can provide invaluable assistance in making informed decisions and ultimately optimizing the performance of the machinery.

Future Trends and Innovations

As we delve into the realm of self-aligning ball bearings and their advantages, it's equally important to consider the future trends and innovations in this field. The world of industrial machinery is ever-evolving, and self-aligning ball bearings are no exception. In this section, we will explore the anticipated trends and innovations in self-aligning ball bearings, shedding light on the advancements in materials and manufacturing techniques and how these innovations will shape the landscape of industrial precision and motion control.

Advancements in Materials

One of the significant trends in the development of self-aligning ball bearings is the continual advancement in materials used for their construction. Traditional materials like steel and chrome alloys have been the staples in bearing manufacturing for years. However, researchers and engineers are actively exploring new materials and alloys that offer enhanced performance, durability, and corrosion resistance.

Advanced ceramics, such as silicon nitride and zirconia, are gaining traction in bearing technology due to their exceptional hardness and resistance to wear. These materials are well-suited for applications where high speeds and extreme temperatures are involved. The adoption of innovative materials will lead to bearings that can operate in more demanding environments while maintaining precision.

Manufacturing Techniques

In addition to material advancements, manufacturing techniques for self-aligning ball bearings are also undergoing significant improvements. Precision engineering and computer-controlled machining have allowed for tighter tolerances and higher consistency in bearing production. This results in bearings that are more reliable and capable of delivering superior performance.

Furthermore, advancements in surface treatment technologies, such as plasma coating and ion implantation, are enhancing the durability and wear resistance of bearing components. These treatments extend the lifespan of bearings and reduce maintenance requirements in industrial applications.

Impact on Industrial Precision and Motion Control

The innovations in materials and manufacturing techniques for self-aligning ball bearings will have a profound impact on industrial precision and motion control. Bearings are critical components in machinery, and their performance directly affects the efficiency and accuracy of processes.

With the adoption of advanced materials and manufacturing methods, self-aligning ball bearings will become even more versatile and capable of handling extreme conditions. This will open up new possibilities for industries where precision and reliability are paramount, such as aerospace, robotics, and medical equipment manufacturing.

In conclusion, the future of self-aligning ball bearings holds exciting prospects, with advancements in materials and manufacturing techniques driving innovation. These developments will not only enhance the performance of self-aligning ball bearings but also contribute to the overall precision and motion control in various industrial applications. As industries continue to demand higher efficiency and reliability, self-aligning ball bearings are poised to play a pivotal role in meeting these expectations.

Conclusion

In the realm of industrial machinery and precision in motion, self-aligning ball bearings stand as unsung heroes. Throughout this article, we've delved into the intricacies of these remarkable components, exploring their advantages, benefits, and even glimpsing into future innovations. As we conclude our journey through the world of self-aligning ball bearings, let's recap their significance, emphasize their essential role across various industries, and encourage industries to harness the multitude of benefits these precision components offer.

Significance of Precision in Motion

Precision in motion is the cornerstone of efficient industrial processes. Whether it's the delicate maneuvers of a robotic arm in a manufacturing facility or the flawless operation of a medical device in a hospital, precision ensures that things work seamlessly. Self-aligning ball bearings play a pivotal role in achieving this precision. Their unique design allows them to adapt to misalignments, reducing friction and wear while maintaining the accuracy of rotational motion. This capability translates into smoother, quieter, and more efficient machinery, which, in turn, leads to higher productivity and reduced maintenance costs.

Essential Role Across Industries

Self-aligning ball bearings are not confined to a single industry or application. They are versatile components that find their place in a multitude of fields, from automotive and aerospace to manufacturing and medical devices. In the automotive sector, these bearings facilitate the smooth operation of steering systems, enhancing driver control and safety. In aerospace, they contribute to the flawless function of critical components, ensuring the reliability of aircraft systems. In manufacturing, self-aligning ball bearings enable precision and consistency in machinery, driving quality and productivity. And in medical devices, they guarantee the accuracy of diagnostics and treatments, safeguarding lives.

Leveraging the Benefits

As we bid farewell to this exploration of self-aligning ball bearings, we urge industries to fully grasp the benefits these precision components offer. The advantages, such as reduced friction, lower maintenance costs, and enhanced machinery performance, are not to be underestimated. By incorporating self-aligning ball bearings into their processes, industries can optimize efficiency, improve reliability, and ultimately stay ahead in today's competitive landscape.

In conclusion, precision in motion is the catalyst for success in various industries, and self-aligning ball bearings are the unsung heroes that make it possible. Their significance in achieving efficiency, reliability, and precision cannot be overstated. Industries that embrace these advantages will undoubtedly position themselves for success in an ever-evolving industrial landscape. So, let us not underestimate the power of precision in motion, for it is the driving force behind progress and innovation.

FAQs: Common Questions About Self-Aligning Ball Bearings

What Are Self-Aligning Ball Bearings, and How Do They Work?

Self-aligning ball bearings are a type of rolling element bearing designed to accommodate misalignment between the shaft and the housing. They consist of two rows of balls and a spherical raceway in the outer ring. This unique design allows the bearing to self-align, compensating for shaft deflections and misalignments. The balls transmit the load between the inner and outer rings while minimizing friction, ensuring smooth rotational motion.

Where Are Self-Aligning Ball Bearings Used?

These bearings find applications in a wide range of industries, including automotive, aerospace, manufacturing, and medical devices. In automotive applications, they are used in steering systems and transmission components. In aerospace, they contribute to the reliable operation of various aircraft systems. Manufacturers rely on them for precision machinery, while medical devices benefit from their accuracy.

What Advantages Do Self-Aligning Ball Bearings Offer?

Self-aligning ball bearings offer several advantages. Their ability to self-align reduces friction, leading to smoother operation and reduced wear. This results in lower maintenance costs and extended bearing life. Moreover, they enhance machinery performance by maintaining accuracy despite misalignments, contributing to increased productivity and efficiency.

Are Self-Aligning Ball Bearings Suitable for High-Speed Applications?

Yes, self-aligning ball bearings can be used in high-speed applications. Their design, which minimizes friction and heat generation, makes them suitable for such scenarios. However, the selection of the appropriate bearing size, lubrication, and operational conditions is crucial to ensure optimal performance at high speeds.

How Can I Choose the Right Self-Aligning Ball Bearings for My Application?

Selecting the right self-aligning ball bearings involves considering factors such as load magnitude, speed, lubrication requirements, and environmental conditions. It's advisable to consult with experts or manufacturers who can provide guidance and assist in choosing the most suitable bearing for your specific application.

What Does the Future Hold for Self-Aligning Ball Bearings?

The future of self-aligning ball bearings looks promising, with expected advancements in materials and manufacturing techniques. These innovations are likely to further enhance their precision and performance. Industries should stay abreast of these developments to harness the benefits of these evolving precision components.

In conclusion, self-aligning ball bearings play a vital role in achieving precision in motion within various industries. Their unique design and numerous advantages make them indispensable in enhancing efficiency, reliability, and productivity. If you have any more questions or need further information about self-aligning ball bearings, feel free to reach out to experts or manufacturers in the field. Your journey toward precision in motion awaits.

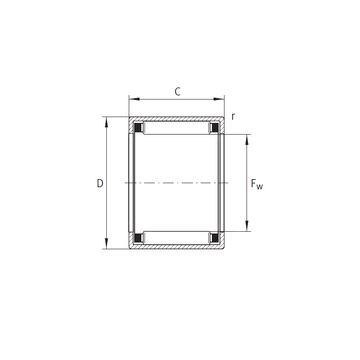

SCE5612 INA Needle Roller Bearings

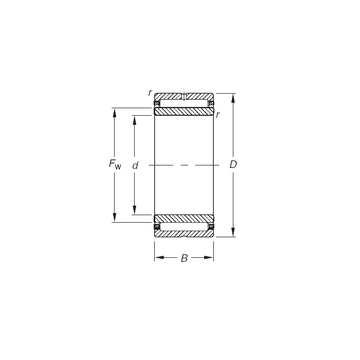

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

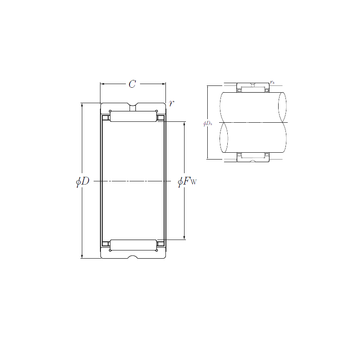

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

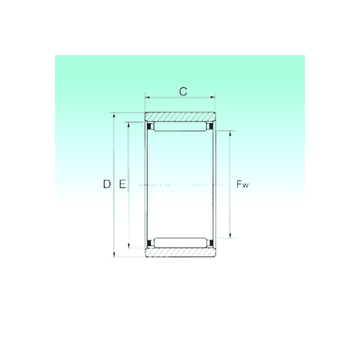

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings