Home> Company News> Efficient Engineering: Harnessing the Power of Combined Needle Roller Bearings

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In the world of engineering, where precision, reliability, and efficiency reign supreme, components like combined needle roller bearings play a pivotal role. These unassuming yet powerful bearings are the unsung heroes behind the seamless operation of various mechanical systems. In this exploration, we delve into the fascinating world of combined needle roller bearings, shedding light on their indispensable role in engineering applications.

The Heart of Engineering Efficiency

Efficiency is the cornerstone of successful engineering, and combined needle roller bearings are at the forefront of achieving this goal. Despite their unassuming appearance, these bearings are engineered to deliver exceptional performance. They form the very foundation upon which a multitude of machinery relies to function optimally.

Our journey will take us through the intricate details of combined needle roller bearings. We will unravel the design principles that make them unique and explore the components that constitute these bearings, including needles, cages, and inner and outer rings. We will delve into their diverse applications across various industries, highlighting their ability to enhance equipment performance and versatility. Moreover, we will discuss the installation and maintenance practices essential for ensuring the longevity and reliability of these bearings.

Design and Construction

In the realm of engineering, where efficiency and precision are paramount, understanding the design and construction of combined needle roller bearings is crucial. These remarkable components serve as the backbone of many mechanical systems, offering a unique combination of load-bearing capabilities and versatility. we will delve into the intricate details of their design and construction, shedding light on what makes them such powerful assets in engineering applications.

The Blueprint of Efficiency

At the heart of every combined needle roller bearing is a meticulously crafted design. To truly harness their power, it's essential to comprehend the principles that govern their construction. These principles are rooted in the pursuit of optimal load distribution, reduced friction, and enhanced durability.

Unveiling the Components

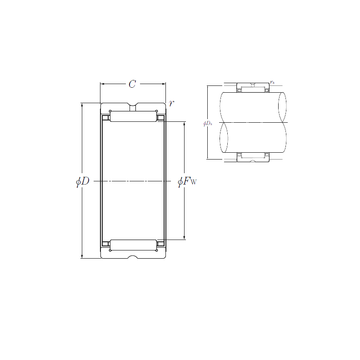

A combined needle roller bearing is more than the sum of its parts, but understanding these parts is key to grasping their inner workings. Within the structure of a combined needle roller bearing, you'll find needles, cages, and inner and outer rings, each with a specific role to play in ensuring the bearing's functionality.

|

Needles |

These are the cylindrical rolling elements that carry and distribute the load. They are designed to minimize friction while providing high load-carrying capacity. Their precise arrangement and geometry are critical to the bearing's performance. |

|

Cages |

Cages, often made of steel or other durable materials, keep the needles evenly spaced and prevent them from coming into direct contact with each other. This minimizes wear and ensures consistent load distribution. |

|

Inner and Outer Rings |

The inner ring is attached to the shaft, while the outer ring is typically housed in the bearing's housing. These rings serve as raceways for the needles and provide the necessary support and guidance for their movement. |

Exploring Variations and Types

The world of combined needle roller bearings is diverse, with a range of variations and types to suit different applications. These variations may include variations in needle design, cage materials, or sealing options. Understanding the available choices is crucial for selecting the right bearing for a specific engineering task.

Applications Across Industries

Combined needle roller bearings, with their remarkable load-carrying capabilities and versatility, find invaluable applications across a wide spectrum of industries. we will explore the diverse range of fields that heavily rely on these engineering marvels to achieve superior performance and efficiency. From automotive transmissions to textile machinery and even medical equipment, the applications of combined needle roller bearings are truly boundless.

Automotive Transmissions: Precision in Motion

The automotive industry demands precision, durability, and efficiency, making it a natural fit for combined needle roller bearings. These bearings play a pivotal role in automotive transmissions, ensuring the smooth transfer of power from the engine to the wheels. By supporting high radial loads and accommodating axial loads, combined needle roller bearings contribute to the overall performance and longevity of a vehicle's drivetrain.

Textile Machinery: Weaving the Fabric of Efficiency

In the textile industry, where the intricacies of fabric production require machinery that operates flawlessly, combined needle roller bearings are instrumental. They are commonly found in the moving parts of textile machines, including spinning frames and looms. Their ability to handle both radial and axial loads with minimal friction ensures the efficient operation of these machines, resulting in consistent and high-quality fabric production.

Medical Equipment: Precision in Healthcare

The healthcare sector relies on precise and reliable equipment to deliver quality patient care. Combined needle roller bearings are utilized in various medical devices, such as X-ray machines, CT scanners, and surgical robots. Their ability to maintain low friction and high load-carrying capacity is essential in these applications, where precision and smooth motion are critical.

Benefits Beyond Boundaries

In each of these industries, the use of combined needle roller bearings offers distinct advantages. Their exceptional load-carrying capacity ensures that machinery can handle heavy workloads without compromising on performance. Additionally, their compact design allows for space-efficient installations, making them suitable for applications with limited space constraints.

Combined needle roller bearings excel in scenarios where precise motion, durability, and versatility are essential. As we continue our exploration, we'll delve into the installation and maintenance of these bearings, providing insights into best practices for ensuring their long-term reliability and efficiency.

Installation and Maintenance

Efficient engineering and the successful harnessing of combined needle roller bearings depend not only on their design and construction but also on their proper installation and ongoing maintenance. In this section, we will provide a comprehensive guide to ensure that these remarkable bearings continue to perform at their peak throughout their service life.

Installation: Precision Matters

Alignment and Tolerance

The first crucial step in installing combined needle roller bearings is ensuring precise alignment. Proper alignment between the shaft and housing minimizes stress and friction, contributing to optimal performance. Engineers should adhere to specified tolerances to prevent misalignment, which can result in premature wear and reduced bearing lifespan.

Torque Specifications

It's essential to follow the manufacturer's torque specifications during installation. Applying the correct torque to fasteners, such as bolts or nuts, ensures that the bearing components are securely held in place. Over-tightening or under-tightening can lead to issues like excessive heat generation, which can compromise bearing functionality.

Maintenance: Extending Longevity

|

Lubrication |

Lubrication plays a vital role in maintaining the efficiency and longevity of combined needle roller bearings. Adequate and appropriate lubrication reduces friction and wear, preventing premature failure. Engineers should consult the manufacturer's recommendations for lubrication intervals and the type of lubricant to use.

|

|

Inspection and Monitoring |

Regular inspections are essential to detect early signs of wear and tear. Visual inspections and condition monitoring can help identify issues such as corrosion, overheating, or abnormal noise. Implementing a proactive maintenance schedule can prevent unexpected breakdowns and production downtime. |

|

Addressing Wear and Tear

|

When wear and tear are identified, addressing them promptly is critical. Replacement of damaged or worn-out components, such as needles or cages, should be carried out following industry best practices. Ignoring these issues can lead to more extensive damage and costly repairs. |

Conclusion

Efficient engineering practices go hand in hand with the proper installation and maintenance of combined needle roller bearings. By ensuring precise alignment during installation, adhering to torque specifications, and implementing regular lubrication and inspections, engineers can extend the longevity of these bearings and maximize their efficiency. In the final section, we will discuss the advantages and limitations of combined needle roller bearings, providing a well-rounded understanding of their role in various engineering applications.

Advantages and Limitations

Combined needle roller bearings offer a unique set of advantages and capabilities that make them a popular choice in various engineering applications. we will explore the strengths and potential limitations of these versatile bearings, shedding light on their role in modern engineering.

Advantages of Combined Needle Roller Bearings

High Load-Carrying Capacity

One of the primary advantages of combined needle roller bearings is their exceptional load-carrying capacity. These bearings can handle both radial and axial loads, making them ideal for applications where forces act in multiple directions simultaneously. This capability ensures that combined needle roller bearings can effectively support heavy loads without compromising performance.

Compact Design

Combined needle roller bearings feature a compact and space-saving design. Their low-profile configuration allows engineers to use them in applications with limited space. This characteristic is particularly beneficial in industries where equipment size and weight are critical factors.

Minimal Friction and Heat Generation

Efficiency is a key concern in engineering, and combined needle roller bearings excel in this regard. Their design minimizes friction, reducing energy losses and heat generation. This not only enhances the efficiency of machinery but also contributes to extended bearing life.

Versatility

Combined needle roller bearings are highly versatile and can be used in a wide range of applications. Whether it's automotive transmissions, textile machinery, or medical equipment, these bearings adapt well to diverse engineering solutions.

Limitations and Considerations

Sensitivity to Misalignment

While combined needle roller bearings offer numerous advantages, they are sensitive to misalignment. Proper alignment during installation is crucial to prevent premature wear and ensure optimal performance. Engineers should pay close attention to alignment tolerances to avoid issues related to misalignment.

Alternative Bearing Solutions

In some engineering applications, alternative bearing solutions may be more suitable. Engineers should carefully evaluate the specific requirements of their projects and consider factors such as load type, speed, and environmental conditions when selecting bearings. It's essential to choose the right bearing for each application to achieve the best results.

Conclusion

Combined needle roller bearings have become an integral part of efficient engineering practices, thanks to their impressive load-carrying capacity, compact design, and minimal friction characteristics. While they offer numerous advantages, it's essential to be mindful of their sensitivity to misalignment and consider alternative bearing solutions when appropriate.

Innovations and Future Trends

In the ever-evolving field of engineering, staying at the forefront of technological advancements is crucial. This section delves into the innovations and future trends in combined needle roller bearings, shedding light on the exciting developments that promise to shape the engineering landscape.

Evolving Trends in Combined Needle Roller Bearings

Advanced Materials

The development of advanced materials is a key trend in combined needle roller bearing technology. Engineers and manufacturers are constantly exploring materials with enhanced durability, increased load-carrying capacity, and superior resistance to wear and corrosion. Innovative materials like ceramics and high-performance polymers are being integrated into bearing design to push the boundaries of performance.

Precision Engineering

As engineering tolerances become increasingly stringent, precision engineering has become a critical trend in bearing design. Combined needle roller bearings are now being manufactured with a focus on achieving exceptionally tight tolerances. This precision not only improves overall performance but also extends the operational lifespan of these bearings.

Lubrication and Sealing

Efficient lubrication and effective sealing mechanisms are areas where significant advancements are being made. Engineers are developing innovative lubrication solutions that reduce friction, minimize heat generation, and enhance overall efficiency. Similarly, improved sealing techniques are crucial in preventing contamination and extending bearing life, especially in challenging environments.

Expected Advancements

Smart Bearings

The integration of smart technology into bearings is an exciting prospect for the future. Smart bearings equipped with sensors and monitoring capabilities can provide real-time data on bearing condition, load, temperature, and more. This data can be invaluable for predictive maintenance, helping engineers identify potential issues before they lead to downtime or failures.

3D Printing and Customization

The advent of 3D printing has opened up new avenues for customization in bearing design. Engineers can now tailor bearings to specific applications, optimizing their performance for unique requirements. This trend is expected to grow, allowing for rapid prototyping and efficient customization of combined needle roller bearings.

Sustainability and Efficiency

In an era of increasing environmental awareness, sustainability and efficiency are at the forefront of engineering trends. Future innovations in combined needle roller bearings will likely focus on reducing energy consumption, minimizing waste, and improving overall environmental impact. Bearings that require less lubrication, generate lower friction, and last longer contribute to a more sustainable engineering ecosystem.

Conclusion

As engineering continues to evolve, combined needle roller bearings remain a vital component in enhancing efficiency and performance. The ongoing trends and future innovations in this field promise to revolutionize engineering practices, enabling more efficient and sustainable solutions across various industries.

Conclusion

In the world of engineering, where precision and efficiency reign supreme, combined needle roller bearings have proven to be indispensable components. Throughout this comprehensive exploration, we've uncovered the significant role that combined needle roller bearings play in enhancing engineering efficiency and performance. As we bring this journey to a close, let's recap the key takeaways and emphasize the importance of harnessing the power of these remarkable bearings.

The Crucial Role of Combined Needle Roller Bearings

Combined needle roller bearings have demonstrated their prowess in handling demanding engineering applications. Their unique design, which combines both needle and thrust bearings, provides engineers with a versatile and reliable solution. These bearings excel in scenarios where high radial and axial loads must be managed simultaneously, making them ideal for a wide range of machinery and equipment.

Unlocking Engineering Efficiency

Efficiency is the heartbeat of successful engineering, and combined needle roller bearings are at its core. Their ability to reduce friction, distribute loads evenly, and operate under challenging conditions contributes significantly to machinery reliability and productivity. By incorporating these bearings into their designs, engineers can optimize performance, minimize downtime, and enhance the overall efficiency of their projects.

Embracing the Future

As we look ahead, the engineering landscape continues to evolve, and combined needle roller bearings are set to evolve with it. Advancements in materials, precision engineering, lubrication, and smart technology are paving the way for even more efficient and sustainable solutions. Engineers of tomorrow will have access to smart bearings that provide real-time data, 3D-printed custom bearings, and eco-friendly designs that reduce environmental impact.

The Call to Action

In conclusion, the role of combined needle roller bearings in efficient engineering cannot be overstated. Their capacity to enhance load-bearing capabilities, reduce friction, and withstand challenging conditions positions them as invaluable assets in various industries. We encourage engineers and industries alike to explore the myriad benefits these components offer and consider their integration into future projects.

Efficient engineering is not merely a goal but a necessity in today's competitive landscape. Combined needle roller bearings stand as a testament to innovation and progress in the field, and their continued use will undoubtedly drive greater success and sustainability across diverse engineering applications.

As we conclude our exploration of combined needle roller bearings, we transition to the frequently asked questions (FAQs) section, where we address common queries and concerns related to these bearings.

FAQs: Common Questions About Combined Needle Roller Bearings

In our exploration of combined needle roller bearings and their pivotal role in engineering, it's essential to address some of the common questions and queries that engineers and professionals often have about these remarkable components. Let's delve into the most frequently asked questions regarding combined needle roller bearings:

What Are Combined Needle Roller Bearings?

- Combined needle roller bearings are specialized bearings designed to handle both radial and axial loads. They consist of needle rollers and a thick outer ring, making them suitable for applications where space is limited.

Where Are Combined Needle Roller Bearings Used?

- These bearings find applications in various industries, including automotive, aerospace, construction, and industrial machinery. They are commonly used in gearboxes, cam followers, and conveyor systems.

What Are the Advantages of Using Combined Needle Roller Bearings?

- Combined needle roller bearings offer high load-carrying capacity, excellent radial stiffness, and the ability to handle both thrust and radial loads. Their compact design makes them ideal for space-constrained applications.

Are There Different Types of Combined Needle Roller Bearings?

- Yes, there are various types, including those with a stud-type or yoke-type design, depending on the application's requirements. Stud-type bearings have a solid stud, while yoke-type bearings have a hole through the center.

5. How Do I Choose the Right Combined Needle Roller Bearing for My Application?

- Selecting the appropriate bearing involves considering factors like load requirements, speed, operating conditions, and available space. Consulting with a bearing expert or manufacturer is often advisable.

What Maintenance is Required for Combined Needle Roller Bearings?

- Proper maintenance includes regular lubrication to reduce friction and prevent premature wear. Additionally, inspecting for any signs of damage or misalignment is essential to ensure longevity.

Can Combined Needle Roller Bearings Handle Misalignment?

- While combined needle roller bearings can tolerate some misalignment, excessive misalignment can lead to premature wear and reduced performance. Proper alignment during installation is crucial.

Are Combined Needle Roller Bearings Cost-Effective?

- Yes, they are cost-effective due to their long service life, high load capacity, and versatility. Their ability to replace multiple components with a single bearing can lead to cost savings.

How Do Innovations Impact Combined Needle Roller Bearings?

- Continuous innovations in materials and manufacturing techniques lead to improved performance, extended service life, and reduced maintenance requirements for combined needle roller bearings.

Where Can I Source High-Quality Combined Needle Roller Bearings?

- Reputable bearing manufacturers and distributors offer a wide range of combined needle roller bearings. Researching and selecting a trusted supplier is essential for obtaining reliable products.

These FAQs provide a fundamental understanding of combined needle roller bearings and their applications in engineering. Whether you're an engineer or a professional in a related field, the versatility and efficiency of combined needle roller bearings make them a valuable component in various machinery and equipment.

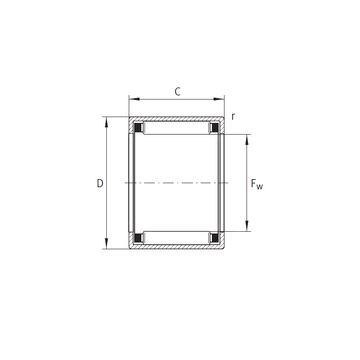

SCE5612 INA Needle Roller Bearings

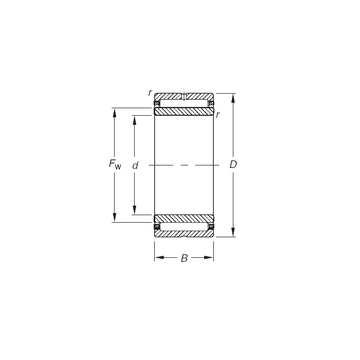

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

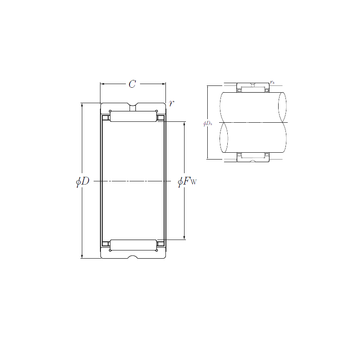

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

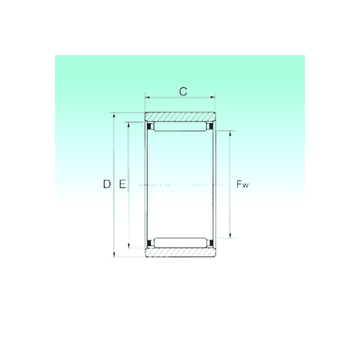

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings