Home> Company News> Unveiling the Power of Thrust Needle Roller Bearings in Europe

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In this comprehensive exploration, we delve into the world of thrust needle roller bearings, focusing on their pivotal role in empowering industries across Europe. This article aims to shed light on the remarkable significance of thrust needle roller bearings in various sectors of European manufacturing. As we embark on this journey, we will uncover the hidden potential and versatility of these precision components, which serve as the unsung heroes behind the efficient machinery that drives European industries.

Thrust needle roller bearings have long been the unsung heroes of machinery, quietly powering countless applications across diverse sectors. From automotive to aerospace, manufacturing to robotics, these unassuming components play a crucial role in ensuring smooth and efficient mechanical operations. As we explore the power of thrust needle roller bearings in Europe, we will delve into their evolution, the commitment to quality and innovation, sustainability practices, and the future trends that will shape the industry.

Evolution of Thrust Needle Roller Bearings

As we journey into the realm of thrust needle roller bearings, it's essential to first understand their evolution and how they have become indispensable to various European industries. This section will delve into the historical development of these precision components and their profound impact on the manufacturing landscape.

Tracing the Historical Development

The history of thrust needle roller bearings can be traced back to the early 20th century when the need for precision bearings became increasingly apparent. The basic concept of needle rollers supporting axial loads was born out of the necessity for robust and efficient mechanical systems. Over the years, engineers and inventors in Europe have made significant contributions to the development of these bearings.

Key Milestones and Innovations

Throughout their evolution, thrust needle roller bearings have witnessed several key milestones and innovations. These advancements have not only enhanced their performance but also expanded their applications across industries. From improved materials to innovative cage designs and lubrication techniques, each milestone has contributed to their effectiveness.

One of the most significant innovations was the introduction of the caged needle roller thrust bearing, which allowed for higher speeds and greater load-carrying capacity. European manufacturers played a pivotal role in perfecting this design, making it a standard in various industries.

European Manufacturers on the Global Stage

European manufacturers of thrust needle roller bearings have carved a unique niche in the global market. Their commitment to quality, precision, and continuous innovation has set them apart. European-made bearings are renowned for their reliability and durability, making them the preferred choice for many industries worldwide.

Furthermore, European manufacturers have established robust supply chains and distribution networks, ensuring a steady supply of these essential components to industries across the globe. Their reputation for excellence has solidified Europe's position as a leader in the production of thrust needle roller bearings.

Quality Standards and Innovation in European Thrust Needle Roller Bearings Production

In the world of manufacturing, especially when it comes to precision components like thrust needle roller bearings, maintaining the highest quality standards and fostering innovation are of paramount importance. In this section, we will explore how European manufacturers have set exemplary benchmarks in these aspects, ensuring their dominance in the global thrust needle roller bearings market.

Commitment to Quality Standards

Quality is the cornerstone of European thrust needle roller bearings production. Manufacturers across the continent adhere to stringent quality standards to deliver bearings that meet or exceed customer expectations. These standards encompass various aspects of production, including materials selection, manufacturing processes, and product testing.

One of the key quality standards that European manufacturers adhere to is ISO 9001 certification. This certification signifies a commitment to quality management systems, ensuring consistency and reliability in every bearing produced. European-made thrust needle roller bearings are known for their precision, reliability, and durability, making them the preferred choice across industries.

Continuous Innovation and Research

European manufacturers understand that innovation is the lifeblood of any industry. They continuously invest in research and development to push the boundaries of what thrust needle roller bearings can achieve. This commitment to innovation extends to materials, design, and technology.

In the realm of materials, European manufacturers are constantly exploring new alloys and composites that enhance bearing performance. These materials offer improved wear resistance, higher load-carrying capacity, and increased durability, all of which are crucial for various industrial applications.

In terms of design, European engineers are at the forefront of developing cutting-edge bearing configurations. These innovative designs optimize load distribution, reduce friction, and enhance overall efficiency. From miniature bearings for delicate instruments to large thrust bearings for heavy machinery, European manufacturers tailor their designs to suit diverse needs.

Europe's Competitiveness in the Global Market

Adherence to quality standards and a commitment to innovation have positioned Europe as a competitive force in the global thrust needle roller bearings market. European-made bearings are trusted worldwide for their precision, reliability, and performance. They play a pivotal role in powering industries not only within Europe but also across the globe.

Moreover, European manufacturers have established efficient supply chains and distribution networks, ensuring that their products reach customers promptly and reliably. This reliability further solidifies Europe's reputation as a leader in thrust needle roller bearings production.

As we proceed, we will uncover more about how these precision components are contributing to the industrial landscape of Europe, powering various sectors and facilitating technological advancements.

Sustainability and Environmental Considerations in European Thrust Needle Roller Bearings Production

In the modern industrial landscape, sustainability and environmental responsibility have become integral aspects of manufacturing. European manufacturers of thrust needle roller bearings have recognized the importance of aligning their production processes with eco-friendly practices. In this section, we will delve into the sustainability initiatives undertaken by European manufacturers and how these practices are contributing to a greener future while maintaining the highest quality standards.

Sustainability Practices in Thrust Needle Roller Bearings Production

European manufacturers have made substantial strides in adopting sustainable practices throughout the lifecycle of thrust needle roller bearings. This begins with the selection of materials, where an emphasis is placed on utilizing recyclable and sustainable resources. Raw materials are sourced responsibly, and the production processes aim for minimal waste generation.

One notable practice is the implementation of closed-loop manufacturing systems. These systems optimize resource utilization by recycling materials within the production cycle, reducing waste, and minimizing environmental impact. European manufacturers actively seek ways to reduce energy consumption and carbon emissions during production, showcasing their commitment to a sustainable future.

Environmental Considerations in Material Selection

The choice of materials in thrust needle roller bearings production significantly influences their environmental footprint. European manufacturers prioritize materials that are not only durable and high-performing but also environmentally friendly. These materials are selected based on their ability to withstand heavy loads, reduce friction, and ensure longevity while minimizing adverse environmental effects.

Many European manufacturers have transitioned to using bio-based lubricants in their bearings. These lubricants are biodegradable and reduce the environmental impact associated with conventional lubricants. This transition aligns with a broader goal of minimizing the ecological footprint of thrust needle roller bearings.

Promoting Sustainability in Machinery and Equipment

Thrust needle roller bearings play a crucial role in various industries, from automotive and aerospace to renewable energy and manufacturing. Their reliability and efficiency directly impact the performance of machinery and equipment. European-made bearings are engineered to operate with minimal friction, resulting in energy savings and reduced wear and tear on machinery.

By contributing to enhanced machinery efficiency, thrust needle roller bearings indirectly promote sustainability across industries. Reduced energy consumption and extended equipment lifespan translate into fewer resources consumed and less waste generated over time.

As we explore further, we will uncover how these sustainable practices not only benefit the environment but also elevate the reputation of European manufacturers as leaders in producing thrust needle roller bearings that meet the highest quality and ecological standards.

The Future of Thrust Needle Roller Bearings Manufacturing: Trends and Outlook

European manufacturers have long been at the forefront of innovation, and they continue to pave the way for the global market. In this section, we will explore the future of thrust needle roller bearings manufacturing, focusing on emerging trends, challenges, and Europe's vision for leadership in the industry.

Anticipating Future Trends

|

Digitalization |

The digitalization of manufacturing processes is a trend that's transforming industries worldwide, and thrust needle roller bearings are no exception. European manufacturers are increasingly integrating digital technologies into their production lines. This includes using advanced sensors and data analytics to monitor bearing performance, predict maintenance needs, and optimize operational efficiency. |

|

Smart Bearings |

Smart bearings are an exciting development on the horizon. These bearings are equipped with sensors and embedded intelligence, enabling real-time monitoring of factors like temperature, load, and lubrication conditions. European manufacturers are investing in research and development to create smart thrust needle roller bearings that can communicate their status to machinery control systems, ensuring proactive maintenance and preventing costly downtime. |

|

Automation |

Automation is a driving force in modern manufacturing. European manufacturers are adopting automated production processes to enhance precision and consistency in thrust needle roller bearings production. Robotics and automated quality control systems are becoming standard in European manufacturing facilities, contributing to higher production volumes and quality standards.

|

Challenges and Opportunities

With innovation comes challenges and opportunities:

Skilled Workforce

Maintaining a skilled workforce is crucial for adopting advanced technologies. European manufacturers are investing in training programs to equip their employees with the necessary skills for digitalization and automation.

Global Competition

European manufacturers face global competition, particularly from Asian markets. However, Europe's commitment to quality, sustainability, and innovation continues to set it apart on the global stage.

Environmental Responsibility

Sustainability remains a top priority. European manufacturers are exploring eco-friendly materials, energy-efficient processes, and waste reduction strategies to align with environmental standards.

Europe's Vision for Leadership

Europe aims to lead the thrust needle roller bearings manufacturing industry on a global scale. European manufacturers are committed to producing bearings that not only meet the highest quality standards but also incorporate cutting-edge technologies for improved performance and reliability.

Through collaboration, research, and innovation, Europe seeks to remain a frontrunner in the field, setting trends and driving the industry's evolution. As we conclude our exploration of the future of thrust needle roller bearings manufacturing, it's evident that Europe's vision for leadership is firmly grounded in technological advancement, sustainability, and a dedication to excellence.

Conclusion

In conclusion, we have embarked on a journey to unveil the power of thrust needle roller bearings in Europe, and the insights gained are truly remarkable. Europe's expertise in thrust needle roller bearings production stands as a testament to its commitment to quality, innovation, and sustainability.

Throughout this exploration, we have learned that thrust needle roller bearings play a pivotal role across various industries in Europe. These precision-engineered components are the silent heroes that enable machinery to function with unmatched efficiency and reliability. From automotive applications to heavy machinery and aerospace, their significance cannot be overstated.

Europe's manufacturers have continually pushed the boundaries of technology and materials to create thrust needle roller bearings that meet the most stringent quality standards. Their dedication to innovation has resulted in bearings that are not only durable but also capable of enhancing the performance of the machinery they serve.

As we reflect on Europe's role in the global landscape of thrust needle roller bearings manufacturing, it becomes evident that the continent is poised to shape the future of this industry. With a focus on digitalization, smart bearings, and automation, European manufacturers are on the cutting edge of technological advancement.

In conclusion, Europe's leadership in thrust needle roller bearings production is anchored in a rich history of innovation, a commitment to quality, and a vision for the future. As we move forward, it is clear that Europe will continue to be a driving force in this vital sector, contributing to the advancement of machinery and industries worldwide. The power of thrust needle roller bearings in Europe is truly unveiled, and the future holds even greater promise.

FAQs: Common Questions About Thrust Needle Roller Bearings

What Are Thrust Needle Roller Bearings?

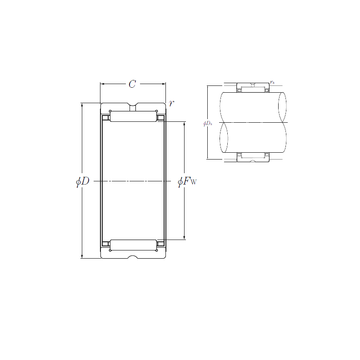

Thrust needle roller bearings are a type of needle roller bearing specially designed to handle axial loads. They consist of needle rollers, held in place by a cage, providing a compact and high-load-bearing solution for axial thrust.

Where Are Thrust Needle Roller Bearings Used in European Industries?

These bearings find extensive applications in European industries, particularly in precision engineering, automotive manufacturing, and aerospace. They are commonly used in transmissions, gearboxes, and aircraft control systems to manage axial loads efficiently.

How Do Thrust Needle Roller Bearings Work?

Thrust needle roller bearings operate on the principle of using needle-like rollers to transmit axial thrust. These rollers are arranged in a cage, ensuring proper alignment and load distribution. This design allows them to handle high axial loads with minimal friction.

What Sets Thrust Needle Roller Bearings Apart From Other Bearings?

Thrust needle roller bearings excel at managing axial loads, making them highly suitable for applications where space is limited, and precise axial movement is crucial. Their compact design and efficiency distinguish them from other bearing types.

What Are the Advantages of Using Thrust Needle Roller Bearings?

These bearings offer several advantages, including high load-carrying capacity, minimal space requirements, and low friction. Their ability to handle both radial and axial loads makes them versatile components in precision machinery.

Can Thrust Needle Roller Bearings Accommodate Radial Loads as Well?

While thrust needle roller bearings are primarily designed for axial loads, they can handle limited radial loads. However, their primary function is to efficiently manage axial thrust while maintaining precision and durability.

How Should I Install and Maintain Thrust Needle Roller Bearings?

Proper installation and maintenance are essential to ensure the optimal performance and longevity of thrust needle roller bearings. Following manufacturer guidelines for mounting, lubrication, and routine inspections is critical.

Are There Different Types of Thrust Needle Roller Bearings?

Yes, there are various types of thrust needle roller bearings, including single-direction and double-direction designs. Some variations feature special cages and coatings to meet specific application requirements.

What Is the Future Outlook for Thrust Needle Roller Bearings in European Industries?

Thrust needle roller bearings are expected to continue playing a pivotal role in European industries. As technology advances and demands for precision engineering solutions grow, these bearings will remain essential in various applications.

Where Can I Source High-Quality Thrust Needle Roller Bearings in Europe?

High-quality thrust needle roller bearings are readily available from reputable manufacturers and distributors across Europe. Sourcing from trusted suppliers ensures reliability and performance in demanding precision engineering applications.

In conclusion, thrust needle roller bearings are indispensable components that power European industries by efficiently handling axial loads and providing precision in various applications. As we wrap up this section, it's evident that these bearings are essential for achieving precision, reliability, and efficiency in European engineering and manufacturing processes.

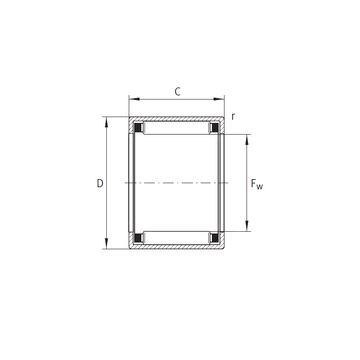

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

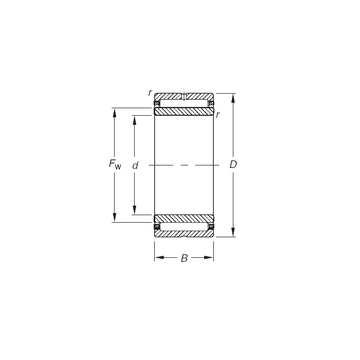

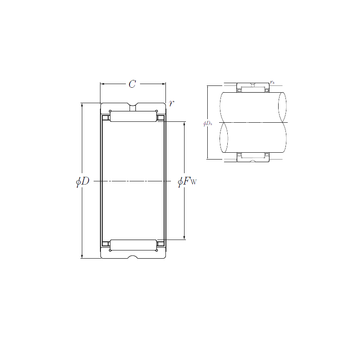

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

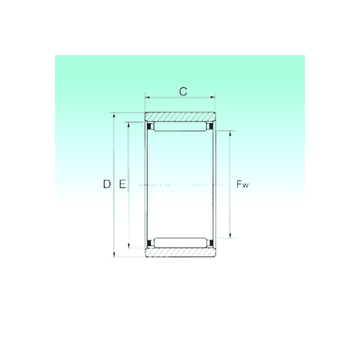

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings