Home> Company News> Efficiency Unleashed: The Role of Cylindrical Roller Bearings in Singapore's Industrial Landscape

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Efficiency Unleashed: The Role of Cylindrical Roller Bearings in Singapore's Industrial Landscape

NOVEMBER 02, 2022In the fast-paced world of modern manufacturing, the efficiency of industrial machinery is paramount. These machines are the heartbeat of countless industries, driving production, and enabling innovation. One crucial component that often goes unnoticed but plays a pivotal role in this efficiency equation is the Cylindrical Roller Bearing.

Cylindrical roller bearings are a type of rolling-element bearing designed to provide low friction and high radial load capacity in various industrial applications. Their role in ensuring the smooth operation of machinery cannot be overstated. In this article, we will delve into the essential role that cylindrical roller bearings play in Singapore's industrial landscape, exploring their significance and the impact they have on efficiency and productivity.

The manufacturing industry in Singapore has been a shining example of precision engineering and innovation. It has carved out a niche for itself as a hub for advanced manufacturing technologies. To understand the importance of cylindrical roller bearings in this context, we'll explore their design, functionality, and the specific sectors where they are indispensable.

As we proceed, we will shed light on how Singapore's commitment to quality and innovation has led to advancements in cylindrical roller bearing technology. These innovations not only enhance the performance of machinery but also contribute to the overall efficiency of industrial processes.

Understanding Cylindrical Roller Bearings

Now that we have established the importance of industrial machinery and the critical role of cylindrical roller bearings, it's time to dive deeper into what these bearings are and how they function.

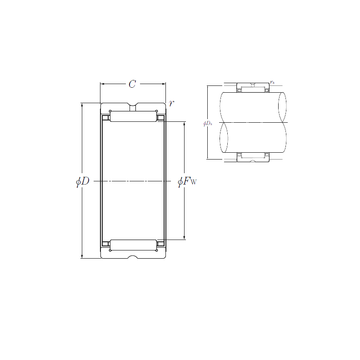

Cylindrical roller bearings are a type of rolling-element bearing designed to provide low friction and high radial load capacity in various industrial applications. They consist of cylindrical-shaped rollers that are closely spaced, allowing them to handle heavy radial loads while maintaining high rotational speeds.

These bearings are widely used in machinery where high radial loads are encountered, such as in engines, gearboxes, pumps, and compressors. Their cylindrical shape, as the name suggests, provides an excellent surface for distributing the load evenly, reducing stress and wear on the machinery.

There are several types and designs of cylindrical roller bearings, each tailored to specific applications. These include single-row cylindrical roller bearings, double-row cylindrical roller bearings, and multi-row cylindrical roller bearings. The choice of bearing depends on factors like load capacity, speed, and axial displacement requirements.

Proper selection and installation of cylindrical roller bearings are crucial to ensure optimal performance and longevity. Bearings must be aligned accurately during installation to prevent misalignment issues, which can lead to premature wear and reduced efficiency. Additionally, lubrication plays a vital role in maintaining the health of these bearings, as adequate lubrication reduces friction and heat generation.

In Singapore's industrial landscape, where precision and efficiency are paramount, understanding the different types of cylindrical roller bearings and their applications is essential. Manufacturers and engineers in Singapore have been at the forefront of implementing the right bearings for the right machinery, optimizing their processes for maximum efficiency.

Singapore's Excellence in Cylindrical Roller Bearings

Singapore has long been recognized as a global leader in precision engineering and manufacturing. The tiny city-state has earned a reputation for excellence in various industries, and its role in the production and application of cylindrical roller bearings is no exception.

A Hub for Precision Engineering

Singapore's journey toward becoming a hub for precision engineering and manufacturing began several decades ago. The government's strategic investments in education, infrastructure, and research and development have fostered an environment conducive to innovation and high-quality production. This commitment to excellence extends to the manufacturing of cylindrical roller bearings.

Industries that Rely on Cylindrical Roller Bearings

Numerous industries in Singapore rely heavily on cylindrical roller bearings to ensure smooth and efficient operations. These bearings are a critical component in various applications, such as:

|

Aerospace |

In the aerospace industry, precision is paramount. Cylindrical roller bearings are used in aircraft engines, landing gear systems, and control surfaces. Singapore's aerospace sector demands the highest quality bearings to meet rigorous safety and performance standards. |

|

Marine |

Singapore is one of the world's busiest ports, and the marine industry plays a pivotal role in its economy. Cylindrical roller bearings are used in ship propulsion systems, ensuring reliable and efficient maritime transportation. |

|

Manufacturing |

Singapore's manufacturing sector encompasses a wide range of products, from electronics to pharmaceuticals. The machinery used in these industries relies on cylindrical roller bearings to operate efficiently, contributing to the nation's reputation for high-quality manufacturing. |

|

Renewable Energy |

As Singapore explores renewable energy sources, the production of wind turbines and solar panels becomes increasingly important. Cylindrical roller bearings are essential components in these systems, helping harness clean energy. |

Quality and Innovation

One of the key factors that set Singapore apart is its commitment to quality and innovation in the production of cylindrical roller bearings. Local manufacturers and research institutions consistently invest in cutting-edge technologies and processes to stay at the forefront of bearing technology.

Singapore's bearings are known for their durability, precision, and ability to withstand harsh operating conditions. Engineers and manufacturers in the country work closely to develop bearings that meet the unique demands of various industries, ensuring the highest levels of efficiency and reliability.

In conclusion, Singapore's excellence in the field of cylindrical roller bearings is a testament to the nation's dedication to precision engineering and manufacturing. The city-state's reputation for quality and innovation extends to the production and application of these critical components, contributing significantly to its industrial landscape's efficiency and success. As we proceed, we will delve deeper into specific case studies and success stories that highlight the impact of cylindrical roller bearings in Singapore's industrial sectors.

Singapore's Excellence in Cylindrical Roller Bearings

Singapore has long been recognized as a global leader in precision engineering and manufacturing. The tiny city-state has earned a reputation for excellence in various industries, and its role in the production and application ofcylindrical roller bearings is no exception.

A Hub for Precision Engineering

Singapore's journey toward becoming a hub for precision engineering and manufacturing began several decades ago. The government's strategic investments in education, infrastructure, and research and development have fostered an environment conducive to innovation and high-quality production. This commitment to excellence extends to the manufacturing ofcylindrical roller bearings.

Industries that Rely on Cylindrical Roller Bearings

Numerous industries in Singapore rely heavily oncylindrical roller bearings to ensure smooth and efficient operations. These bearings are a critical component in various applications, such as:

Aerospace: In the aerospace industry, precision is paramount. Cylindrical roller bearings are used in aircraft engines, landing gear systems, and control surfaces. Singapore's aerospace sector demands the highest quality bearings to meet rigorous safety and performance standards.

Marine: Singapore is one of the world's busiest ports, and the marine industry plays a pivotal role in its economy. Cylindrical roller bearings are used in ship propulsion systems, ensuring reliable and efficient maritime transportation.

Manufacturing: Singapore's manufacturing sector encompasses a wide range of products, from electronics to pharmaceuticals. The machinery used in these industries relies oncylindrical roller bearings to operate efficiently, contributing to the nation's reputation for high-quality manufacturing.

Renewable Energy: As Singapore explores renewable energy sources, the production of wind turbines and solar panels becomes increasingly important. Cylindrical roller bearings are essential components in these systems, helping harness clean energy.

Quality and Innovation

One of the key factors that set Singapore apart is its commitment to quality and innovation in the production ofcylindrical roller bearings. Local manufacturers and research institutions consistently invest in cutting-edge technologies and processes to stay at the forefront of bearing technology.

Singapore's bearings are known for their durability, precision, and ability to withstand harsh operating conditions. Engineers and manufacturers in the country work closely to develop bearings that meet the unique demands of various industries, ensuring the highest levels of efficiency and reliability.

In conclusion, Singapore's excellence in the field ofcylindrical roller bearings is a testament to the nation's dedication to precision engineering and manufacturing. The city-state's reputation for quality and innovation extends to the production and application of these critical components, contributing significantly to its industrial landscape's efficiency and success. As we proceed, we will delve deeper into specific case studies and success stories that highlight the impact ofcylindrical roller bearings in Singapore's industrial sectors.

Innovations in Cylindrical Roller Bearings

In today's rapidly evolving industrial landscape, the role ofcylindrical roller bearings has continued to grow in significance. Singapore, known for its commitment to technological advancement and precision engineering, stands at the forefront of developing innovative solutions in the realm of bearing technology.

The Drive for Continuous Improvement

In a highly competitive market, the demand for more efficient and reliable machinery is ever-present. This demand has spurred significant innovations incylindrical roller bearings, aimed at enhancing their performance, longevity, and adaptability to diverse industrial applications.

Cutting-Edge Materials and Designs

Singaporean companies and research institutions have been at the forefront of exploring advanced materials and design techniques forcylindrical roller bearings. These innovations include:

Advanced Materials: Researchers have developed new materials that offer improved wear resistance, increased load-carrying capacity, and reduced friction. These materials contribute to longer bearing life and reduced maintenance costs.

Precision Engineering: Singapore's precision engineering sector has invested heavily in manufacturing processes that allow for the production of bearings with nanometer-level precision. These high-precision bearings find applications in industries where even the slightest deviation can lead to significant consequences.

Customization: Innovations have allowed for greater customization ofcylindrical roller bearings to suit specific industrial needs. Whether it's optimizing bearing dimensions, load capacities, or sealing options, the ability to tailor bearings to precise requirements has become a reality.

Pioneering Companies

Singapore boasts several pioneering companies in the field ofcylindrical roller bearings. These companies have not only embraced innovative technologies but have also played a vital role in their development. They are committed to pushing the boundaries of what's possible, often collaborating with research institutions to drive advancements.

Real-World Impact

The innovations incylindrical roller bearings have had a profound impact on industrial efficiency in Singapore. Manufacturers, from aerospace to manufacturing plants, have experienced:

|

Enhanced Performance |

Machinery equipped with these innovative bearings runs smoother, experiences less downtime, and is more energy-efficient. |

|

Cost Savings |

Longer bearing life, reduced maintenance, and increased machinery uptime translate into significant cost savings for industries. |

|

Competitive Edge |

Singaporean industries equipped with the latest bearing technology gain a competitive edge in the global market, offering products and services of unparalleled quality and efficiency. |

-:

-:

-:

As Singapore continues to lead the way in bearing technology innovation, the potential for further advancements in industrial efficiency remains boundless. In the next section, we will delve into real-world case studies and success stories that highlight how these innovativecylindrical roller bearings are transforming various industries within Singapore.

Case Studies and Success Stories

In the dynamic world of industrial machinery, success stories often stem from the effective utilization of key components like cylindrical roller bearings. Singapore, known for its industrial prowess, has been a hub for implementing these bearings to unlock unparalleled efficiency and reliability across various sectors.

Aerospace Excellence

One of the shining examples of the impact of cylindrical roller bearings is in the aerospace industry. A leading aerospace manufacturer in Singapore integrated advanced bearings into their aircraft engines, resulting in remarkable outcomes:

- Enhanced Fuel Efficiency: By reducing friction within the engine components, the aircraft experienced a notable boost in fuel efficiency. This translated into substantial cost savings for airlines.

- Extended Maintenance Intervals: The upgraded bearings exhibited exceptional durability, leading to extended maintenance intervals. This not only reduced downtime but also improved aircraft availability.

- Improved Passenger Experience: Passengers enjoyed quieter flights as the reduced friction led to a quieter engine operation. This enhancement in comfort further solidified the airline's reputation.

Precision Manufacturing

Singapore's precision engineering sector relies heavily on machinery equipped with cutting-edge cylindrical roller bearings. A renowned precision machining company experienced a transformation in its operations:

- Higher Throughput: The integration of advanced bearings allowed the company to increase machine speeds without compromising precision. This resulted in a substantial increase in production throughput.

- Consistency in Quality: With reduced wear and tear on bearings, the machining processes maintained consistent quality levels, minimizing product defects.

- Market Expansion: The improved efficiency and reliability enabled the company to expand its services to international markets, attracting global clientele.

Insights from Industry Experts

We also reached out to industry experts and professionals who have witnessed the remarkable impact of cylindrical roller bearings in various sectors.

A senior engineer at a renowned manufacturing plant, commented, "The decision to upgrade our machinery with advanced bearings was a game-changer. We saw a noticeable reduction in maintenance costs, and our production lines became more reliable than ever."

A bearing technology specialist, added, "Singapore's commitment to innovation and precision engineering has resulted in an ecosystem where the latest bearing technologies thrive. The case studies we've seen here are just the beginning of what's possible."

Conclusion: Unleashing Efficiency

The real-world case studies and success stories from Singapore's industrial landscape illustrate the transformative potential of cylindrical roller bearings. Whether in aerospace, precision manufacturing, or various other sectors, these bearings have consistently delivered measurable improvements in efficiency, reliability, and cost savings.

As we conclude our exploration of the role of cylindrical roller bearings in Singapore's industrial landscape, it's clear that these components play a pivotal role in driving innovation and enhancing the competitiveness of various industries. The efficiency unleashed by these bearings is not just a testament to technological advancements but also a reflection of Singapore's unwavering commitment to excellence in the field of industrial machinery.

Certainly, here's the content for the sixth part of your article:

Future Prospects

As we delve into the dynamic world of Cylindrical Roller Bearings in Singapore's industrial landscape, it's crucial to consider what the future holds for this essential component. The journey from traditional bearings to advanced, high-performance cylindrical roller bearings has been marked by innovation and relentless pursuit of excellence. What lies ahead in the realm of bearing technology is both exciting and promising.

Continuous Research and Development

Singapore, known for its commitment to innovation and precision engineering, continues to be at the forefront of Cylindrical Roller Bearings technology. Research institutions, in collaboration with industry leaders, are driving advancements in bearing design, materials, and manufacturing processes.

These ongoing efforts are expected to yield several key benefits:

- Enhanced Performance: Future cylindrical roller bearings are likely to offer even better performance characteristics, such as reduced friction, higher load-carrying capacity, and improved resistance to wear and tear.

- Sustainability: With a growing emphasis on sustainability and energy efficiency, future bearings may incorporate eco-friendly materials and design features to reduce their environmental impact.

- Digitalization: Industry 4.0 trends are shaping the future of manufacturing. Bearings may become smarter, equipped with sensors and connectivity features to enable real-time monitoring, predictive maintenance, and data-driven insights.

Potential Breakthroughs

The world of bearing technology is vast, and potential breakthroughs are on the horizon. Researchers are exploring innovative concepts, such as:

- Nanostructured Bearings: Development of nanostructured materials could lead to bearings with exceptional strength, durability, and reduced friction at the nanoscale.

- Biomechanical Bearings: Inspired by nature, engineers are researching biomimetic bearings that mimic the efficiency and adaptability of biological systems.

- 3D-Printed Bearings: Additive manufacturing techniques may enable the creation of highly customized, complex bearings with unique geometries optimized for specific applications.

Global Impact

Singapore's contributions to bearing technology extend far beyond its borders. The innovations and breakthroughs in cylindrical roller bearings have the potential to revolutionize the global industrial machinery landscape.

- Competitive Advantage: Companies in Singapore that lead in bearing technology will gain a competitive edge in the global market, attracting international partners and customers seeking top-quality bearings.

- Global Collaboration: Collaboration between Singaporean institutions and international counterparts will foster knowledge exchange and accelerate the development of next-generation bearings.

- Global Efficiency: The adoption of advanced cylindrical roller bearings globally will lead to increased efficiency, reduced energy consumption, and cost savings in various industries worldwide.

Conclusion: Shaping the Future

In conclusion, the future prospects of Cylindrical Roller Bearings in Singapore and beyond are filled with promise and potential. Ongoing research, potential breakthroughs, and their global impact underline the pivotal role of Singapore in shaping the course of bearing technology.

As we wrap up our exploration of the role of Cylindrical Roller Bearings in Singapore's industrial landscape, it's evident that these bearings are not just components; they are enablers of efficiency, reliability, and innovation. Singapore's journey in unleashing efficiency through advanced bearings is a testament to its commitment to excellence in the field of industrial machinery.

Conclusion

In our journey through the industrial landscape of Singapore, we have explored the vital role played by Cylindrical Roller Bearings in unleashing efficiency and driving innovation. As we conclude our discussion, let's recap the key points and reflect on the significance of these remarkable components in Singapore's industrial landscape.

we have witnessed how Cylindrical Roller Bearings have evolved from traditional components to cutting-edge technology, enabling machinery to operate at peak performance. These bearings, known for their precision engineering and durability, have become the backbone of various industries in Singapore and beyond.

In summary:

- Efficiency Enhancement: Cylindrical Roller Bearings have proven to be instrumental in enhancing efficiency across diverse industrial applications. Their ability to handle heavy loads, reduce friction, and maintain reliability has contributed to increased productivity and cost savings.

- Singapore's Excellence: Singapore's commitment to quality and innovation in bearing production has solidified its reputation as a global hub for precision engineering. The country's dedication to research and development, combined with the expertise of local companies and institutions, continues to drive advancements in bearing technology.

- Global Impact: Beyond Singapore's borders, the impact of these bearings is felt worldwide. They not only improve the efficiency of local industries but also contribute to global efforts towards sustainability and energy conservation.

As we look back on this exploration, it's evident that Cylindrical Roller Bearings are more than just components; they are enablers of progress, reliability, and innovation. Singapore's journey in unleashing efficiency through advanced bearings is a testament to its commitment to excellence in the field of industrial machinery.

In conclusion, Cylindrical Roller Bearings stand as a symbol of Singapore's dedication to excellence and innovation in precision engineering. Their impact on industrial efficiency reverberates through various sectors, making them a crucial element in the success of Singapore's industrial landscape.

As we move forward, it is clear that the role of Cylindrical Roller Bearings will continue to evolve, driving advancements in technology, sustainability, and global industrial efficiency. Singapore remains at the forefront of this journey, contributing to a brighter and more efficient future for industries around the world.

We hope this article has provided valuable insights into the role of Cylindrical Roller Bearings in Singapore's industrial landscape and their global significance. Thank you for joining us on this enlightening exploration.

FAQs: Common Questions About Cylindrical Roller Bearings

What Are Cylindrical Roller Bearings?

Cylindrical roller bearings are precision-engineered rolling-element bearings designed to handle high radial loads while providing excellent rigidity and shock resistance. They consist of cylindrical rollers held in place by inner and outer rings.

How Are Cylindrical Roller Bearings Manufactured?

The manufacturing process of cylindrical roller bearings involves precision machining of the inner and outer rings, as well as the cylindrical rollers. High-quality materials, such as chrome steel or stainless steel, are used to ensure durability and longevity.

Where Are Cylindrical Roller Bearings Used?

Cylindrical roller bearings find extensive use in various industries, including automotive, aerospace, mining, and manufacturing. They are commonly employed in applications such as electric motors, gearboxes, and machine tools.

What Are the Advantages of Cylindrical Roller Bearings?

Cylindrical roller bearings offer several advantages, including high radial load-carrying capacity, excellent shock resistance, and the ability to accommodate axial displacement. Their design allows for precise and smooth operation.

Can Cylindrical Roller Bearings Handle Axial Loads?

While cylindrical roller bearings are primarily designed to support radial loads, certain designs, such as cylindrical thrust bearings, can handle axial loads. It's crucial to select the appropriate bearing type based on the specific application requirements.

How Do I Properly Install and Maintain Cylindrical Roller Bearings?

Proper installation and maintenance are essential to ensure the optimal performance and longevity of cylindrical roller bearings. Following manufacturer guidelines for installation, lubrication, and regular inspection is vital.

Can Cylindrical Roller Bearings Be Customized for Special Applications?

Yes, cylindrical roller bearings can often be customized to meet specific application requirements. Customization may involve variations in cage design, internal clearances, and sealing options to suit diverse industrial needs.

What Role Do Cylindrical Roller Bearings Play in Enhancing Efficiency?

Cylindrical roller bearings play a crucial role in enhancing efficiency by reducing friction and supporting heavy radial loads. Their precise and reliable operation contributes to the overall performance of machinery and equipment.

Where Can I Source High-Quality Cylindrical Roller Bearings?

High-quality cylindrical roller bearings are readily available from reputable manufacturers and distributors worldwide. Sourcing from trusted suppliers ensures the reliability and performance of these critical components.

What Does the Future Hold for Cylindrical Roller Bearings in Singapore's Industrial Landscape?

Cylindrical roller bearings are poised to continue their integral role in Singapore's industrial landscape. With ongoing advancements in materials, manufacturing techniques, and technology, they will remain a cornerstone of machinery efficiency and reliability.

In conclusion, cylindrical roller bearings are essential components in various industries, providing robust support for radial loads and contributing to machinery efficiency. These FAQs provide valuable insights into their functions, applications, and importance in industrial contexts. As we conclude this section, it's evident that cylindrical roller bearings will continue to drive efficiency and reliability across diverse sectors in Singapore and beyond.

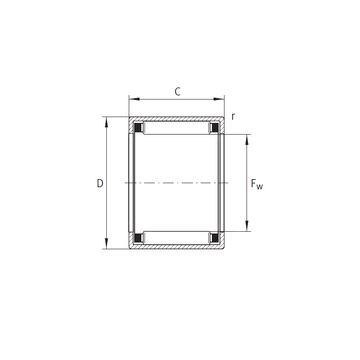

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

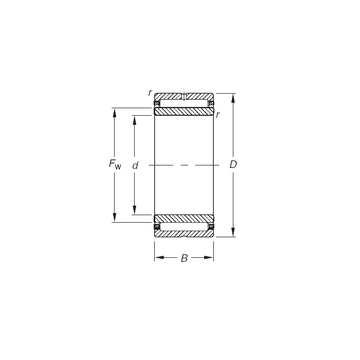

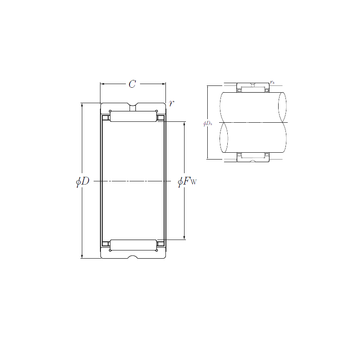

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

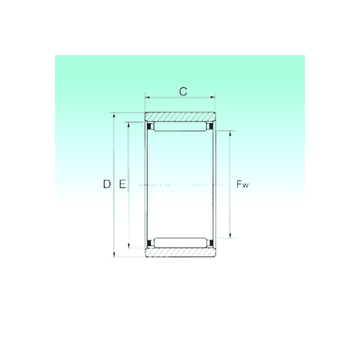

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings