Home> Company News> Unlocking the Potential of Cylindrical Roller Bearings in Europe

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Cylindrical roller bearings are a critical component in numerous industrial applications, and in Europe, their role is more pronounced than ever before. In this article, we will delve into the world of cylindrical roller bearings and explore how they are unlocking vast potential in European industries. From enhancing efficiency to enabling innovation, these bearings are pivotal in shaping the industrial landscape of Europe.

The Role of Cylindrical Roller Bearings

To understand the significance of cylindrical roller bearings, one must first recognize their primary function. These bearings are engineered to facilitate smooth and precise motion in machinery and equipment. They achieve this by reducing friction between moving parts, ensuring that operations run efficiently and with minimal wear.

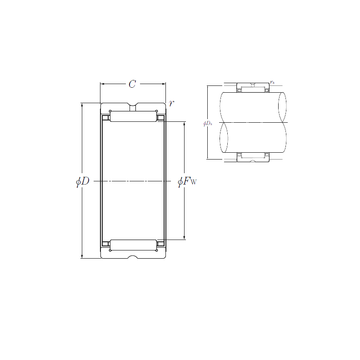

Cylindrical roller bearings, as the name suggests, consist of cylindrical rollers that serve as rolling elements. These rollers are guided by inner and outer rings, and their unique design allows them to handle both radial and axial loads. This versatility makes cylindrical roller bearings invaluable across a wide range of applications.

Diverse Applications

Cylindrical roller bearings find applications in various European industries, spanning from automotive to aerospace, manufacturing to energy. Their ability to handle heavy radial loads makes them ideal for the automotive sector, where vehicles rely on precise and efficient wheel rotation. In the aerospace industry, these bearings play a crucial role in ensuring the smooth functioning of critical components. In manufacturing, they are used in conveyor systems and machining equipment.

we will explore the advantages of cylindrical roller bearings, their specific applications in Europe, recent innovations in bearing technology, adherence to quality standards, and future prospects in the European industrial landscape.

Advantages of Cylindrical Roller Bearings

Cylindrical roller bearings, often referred to as cylindrical bearings, are renowned for their exceptional qualities and unique design. In this section, we will delve into the advantages and characteristics that set cylindrical roller bearings apart, emphasizing their pivotal role in diverse European industries.

|

Handling Heavy Radial Loads |

One of the primary advantages of cylindrical roller bearings is their remarkable capability to handle heavy radial loads. This feature makes them indispensable in applications where machines and equipment need to support substantial weight while maintaining precise motion. In the European automotive industry, for example, where vehicles operate under varying conditions and loads, cylindrical roller bearings ensure the smooth rotation of wheels and transmission components, contributing to vehicle performance and safety. |

|

High-Speed Applications |

Cylindrical roller bearings are also well-suited for high-speed applications. Their unique design allows for efficient lubrication and reduced friction, making them ideal for machinery that operates at elevated speeds. In Europe's manufacturing sector, where conveyor systems and machining equipment demand reliable and efficient performance, cylindrical roller bearings play a crucial role in ensuring uninterrupted production processes. |

|

Handling Misalignment |

Another advantage of cylindrical roller bearings is their ability to accommodate misalignment. This flexibility is essential in applications where components may not align perfectly due to variations in manufacturing or external forces. In such cases, cylindrical roller bearings ensure that machinery can continue to operate smoothly, reducing the risk of damage and downtime. This characteristic is particularly valuable in the aerospace industry, where precision and reliability are paramount.

|

|

Suitability for European Industries |

The versatility of cylindrical roller bearings extends to various European industries. Their ability to handle heavy loads, high speeds, and misalignment makes them a preferred choice across sectors such as automotive, manufacturing, aerospace, and energy. Whether it's in the automotive assembly lines of Germany, the aerospace manufacturing facilities of France, or the energy production plants in Scandinavia, cylindrical roller bearings contribute to the efficiency and reliability of critical processes. |

In the subsequent sections of this article, we will delve deeper into the specific applications of cylindrical roller bearings in Europe, recent innovations in bearing technology, the importance of adhering to quality standards, and the future prospects of these bearings in the European industrial landscape. As we continue our exploration, you will gain a comprehensive understanding of how cylindrical roller bearings are unlocking their potential and driving excellence across European industries.

Applications of Cylindrical Roller Bearings in Europe

Cylindrical roller bearings have proven to be indispensable components in various industries across Europe. In this section, we will explore the wide array of applications where cylindrical roller bearings excel, underscoring their significance in bolstering industrial operations and innovation throughout the continent.

Automotive Industry

One of the prominent sectors where cylindrical roller bearings find extensive use in Europe is the automotive industry. These bearings play a pivotal role in supporting the wheels, transmissions, and engines of vehicles, ensuring optimal performance and safety. Whether it's in the assembly of German luxury cars or the production of efficient compact cars in Italy, cylindrical roller bearings contribute to the seamless motion and reliability of automobiles.

Manufacturing and Machinery

In Europe's manufacturing landscape, where precision and efficiency are paramount, cylindrical roller bearings are a common sight. These bearings are integral to various types of machinery, including conveyor systems, industrial robots, and machining equipment. Their ability to handle heavy loads and high speeds ensures the smooth operation of manufacturing processes, driving productivity and product quality.

Aerospace and Defense

The aerospace and defense industry in Europe demands uncompromised precision and reliability, making cylindrical roller bearings a natural choice. These bearings are utilized in aircraft engines, missile systems, and navigation equipment, where their ability to handle high-speed rotation and misalignment is critical. European aerospace manufacturers rely on cylindrical roller bearings to ensure the safety and performance of their advanced aircraft and defense systems.

Energy and Power Generation

Cylindrical roller bearings also have a significant role to play in Europe's energy and power generation sector. From wind turbines in the windy plains of Denmark to hydroelectric generators in the Alpine regions, these bearings are essential in harnessing energy efficiently. They withstand the challenging conditions of power generation, contributing to sustainable energy production across the continent.

Railway and Transportation

Europe's extensive railway network relies on cylindrical roller bearings for the smooth and reliable operation of trains. These bearings support various components, including axles and wheelsets, ensuring passenger and cargo trains can traverse the continent efficiently. The dependability of cylindrical roller bearings is essential for maintaining the integrity of Europe's rail infrastructure.

Marine and Shipping

In maritime applications, cylindrical roller bearings find their place in ship propulsion systems and cargo handling equipment. European ports and shipping companies depend on these bearings to facilitate the movement of goods and people, contributing to the region's trade and logistics.

Real-World Examples

To illustrate the real-world impact of cylindrical roller bearings in Europe, consider the case of a high-speed train manufacturer in France. The precise and robust nature of these bearings allows the train's wheels to rotate smoothly at high speeds, offering passengers a comfortable and efficient travel experience. In the renewable energy sector, cylindrical roller bearings in offshore wind turbines off the coast of the United Kingdom enable the generation of clean energy, powering homes and industries.

As we continue to explore the potential and versatility of cylindrical roller bearings in Europe, we will delve into recent innovations in bearing technology, the importance of adhering to quality standards, and the outlook for these bearings in the ever-evolving industrial landscape of the continent. With a solid understanding of their applications, you will gain a comprehensive appreciation for how cylindrical roller bearings unlock possibilities and contribute to Europe's industrial growth.

Innovations and Advancements in Cylindrical Roller Bearings

we will delve into the remarkable innovations and advancements that have propelled cylindrical roller bearings to the forefront of modern engineering solutions in Europe. These innovations have not only expanded the applications of these bearings but have also significantly improved their performance and reliability.

Materials and Manufacturing Techniques

Recent innovations in materials science have led to the development of advanced materials for cylindrical roller bearings. These materials exhibit exceptional strength, durability, and resistance to wear and corrosion. For instance, the use of high-grade stainless steels and specialized alloys has enhanced the bearing's ability to withstand harsh operating conditions, making them suitable for applications in marine, aerospace, and heavy industries.

Manufacturing techniques have also evolved to achieve greater precision in the production of cylindrical roller bearings. Computer Numerical Control (CNC) machining and advanced grinding processes ensure that the components of these bearings are manufactured to exacting tolerances. This level of precision contributes to improved performance and extends the bearing's operational life.

Lubrication and Sealing

Efficient lubrication is crucial to the smooth operation and longevity of cylindrical roller bearings. Recent advancements in lubrication technology have led to the development of specialized lubricants tailored to the unique requirements of these bearings. These lubricants offer enhanced load-carrying capabilities, reduced friction, and improved wear resistance.

Additionally, sealing technologies have advanced to provide superior protection against contaminants and moisture. Advanced seals prevent the ingress of foreign particles and ensure that the lubricant remains in optimal condition. This is particularly beneficial in applications where cleanliness and reliability are paramount, such as the food and pharmaceutical industries.

Design and Performance

Innovations in bearing design have optimized the geometry of cylindrical roller bearings for specific applications. Engineers can now choose from a variety of designs, including single-row, double-row, and multi-row configurations, each tailored to meet the unique demands of the intended use. These design innovations ensure that the bearings provide maximum load-carrying capacity while minimizing friction and heat generation.

Moreover, advancements in computer-aided design (CAD) and simulation tools enable engineers to model and analyze the behavior of cylindrical roller bearings under various operating conditions. This enables them to fine-tune the bearing's design for optimal performance, reliability, and efficiency.

Environmental Considerations

In response to growing environmental concerns, innovations in cylindrical roller bearing technology have also focused on sustainability. Manufacturers are increasingly adopting eco-friendly practices, including the use of environmentally friendly lubricants and materials. These efforts align with Europe's commitment to sustainability and contribute to reducing the environmental footprint of industrial processes that rely on cylindrical roller bearings.

These innovations collectively drive the adoption of cylindrical roller bearings across Europe. From automotive and manufacturing to aerospace and renewable energy, these bearings have become integral to a wide range of applications, offering unparalleled performance, reliability, and efficiency. As we conclude our exploration of the innovations in cylindrical roller bearings, we will summarize the key takeaways and highlight the transformative impact of these advancements on European industries.

Quality Standards and Manufacturing of Cylindrical Roller Bearings

we will delve deeper into the critical aspects of quality standards and the intricate manufacturing processes associated with cylindrical roller bearings. The emphasis on maintaining high-quality standards in production is paramount to unleash the full potential of these essential components within the European industrial landscape.

Emphasizing Quality Standards

The foundation of the cylindrical roller bearing industry is built upon stringent quality standards. Ensuring compliance with these standards is not just a best practice; it's a necessity to guarantee the integrity and functionality of cylindrical roller bearings, especially in applications where precision and reliability are non-negotiable.

One of the most widely recognized quality standards in the world is the ISO 9001 certification. Manufacturers who achieve ISO 9001 certification demonstrate their unwavering commitment to consistently meet customer and regulatory requirements. It encompasses various quality management principles, including a strong customer focus, involvement of top management, a process approach, and continuous improvement.

Manufacturing Processes for Precision and Reliability

The manufacturing of cylindrical roller bearings involves a series of intricate processes, each meticulously designed to ensure precision and reliability. These processes are critical in creating bearings capable of withstanding heavy loads, high-speed applications, and demanding operating conditions often encountered in European industries.

|

Raw Material Selection |

The journey towards exceptional cylindrical roller bearings begins with the selection of high-quality materials. Specialized steel alloys are chosen based on their mechanical properties, ensuring the raw materials possess the necessary characteristics for exceptional bearing performance. The quality of these raw materials has a direct impact on the longevity and performance of the bearings. |

|

Turning and Machining |

Precision machining is a fundamental step in creating the various components of cylindrical roller bearings. Inner and outer races, rollers, and cages are expertly crafted using state-of-the-art Computer Numerical Control (CNC) machining and grinding processes. These processes are vital for achieving the tight tolerances and optimal surface finishes required for high-performance bearings. |

|

Heat Treatment |

Heat treatment is employed to enhance the hardness and toughness of bearing components. This critical step ensures that the bearings can endure heavy loads and resist wear and tear over time, a crucial aspect of reliability in European industries. |

|

Assembly |

The assembly process involves fitting the various components together, including the rollers and cages within the races. Proper assembly techniques are imperative to maintaining the desired clearances and tolerances, ultimately ensuring the bearing functions optimally. |

|

Quality Control |

Throughout the manufacturing process, rigorous quality control measures are implemented. Dimensional checks, material analysis, and various testing methods are employed to identify any deviations from the required specifications. This relentless pursuit of quality assurance guarantees the integrity of each bearing produced. |

The Role of Reputable Manufacturers

Reputable manufacturers play a pivotal role in meeting the stringent demands of European industries for high-quality cylindrical roller bearings. They invest significantly in state-of-the-art facilities, employ highly skilled engineers and technicians, and continually innovate to enhance bearing performance.

Collaboration with trusted manufacturers ensures a consistent supply of cylindrical roller bearings that meet the strictest quality standards. This partnership enhances the overall efficiency and competitiveness of various sectors, including the automotive, aerospace, manufacturing, and more, contributing significantly to the growth of European industries.

In conclusion, unwavering adherence to rigorous quality standards and the employment of advanced manufacturing processes are imperative for unlocking the potential of cylindrical roller bearings in Europe. These bearings are the cornerstone of countless industrial applications, and their precision and reliability are indispensable to the success of European industries. As we conclude our exploration of quality standards and manufacturing processes, we will summarize the key takeaways and underscore their significance in the European industrial landscape.

FAQs: Common Questions About Cylindrical Roller Bearings

we will explore some of the most frequently asked questions about cylindrical roller bearings. These versatile and essential components play a vital role in various industries across Europe, and understanding their features and applications is crucial for those seeking efficient and reliable bearing solutions.

What Are Cylindrical Roller Bearings?

Cylindrical roller bearings are a type of rolling element bearing characterized by cylindrical-shaped rollers. These bearings provide high radial load capacity and moderate axial load capacity, making them suitable for a wide range of applications.

Where Are Cylindrical Roller Bearings Commonly Used?

Cylindrical roller bearings are widely used in industries such as automotive, aerospace, manufacturing, and construction. They are commonly found in applications such as electric motors, gearboxes, and machine tools.

What Sets Cylindrical Roller Bearings Apart from Other Bearing Types?

Cylindrical roller bearings are distinguished by their cylindrical rollers, which provide excellent radial load-carrying capacity. Their design allows them to handle both radial and axial loads, making them versatile for various applications.

What Are the Advantages of Using Cylindrical Roller Bearings?

Some key advantages of cylindrical roller bearings include their high load-carrying capacity, ability to handle both radial and axial loads, and suitability for high-speed applications. They are also known for their durability and long service life.

Are There Different Types of Cylindrical Roller Bearings?

Yes, there are several variations of cylindrical roller bearings, including single row, double row, and full complement designs. Each type has unique features and is suitable for specific load and speed requirements.

How Do Cylindrical Roller Bearings Enhance Industrial Efficiency?

Cylindrical roller bearings play a crucial role in enhancing industrial efficiency by providing reliable and low-friction motion control. They help reduce energy consumption and maintenance costs while improving the overall performance of machinery.

Can Cylindrical Roller Bearings Handle High Temperatures and Harsh Environments?

Cylindrical roller bearings are available in various materials and designs to suit different operating conditions. Some variations are designed to withstand high temperatures and harsh environments, making them suitable for demanding applications.

Where Can I Find Quality Cylindrical Roller Bearings in Europe?

High-quality cylindrical roller bearings are available from reputable bearing manufacturers and distributors across Europe. It is essential to source bearings from trusted suppliers to ensure their performance and reliability.

What Maintenance Practices Are Recommended for Cylindrical Roller Bearings?

Regular maintenance is essential to extend the lifespan of cylindrical roller bearings. This includes proper lubrication, monitoring of operating conditions, and periodic inspections for signs of wear or damage. Manufacturers often provide guidelines for maintenance specific to their bearings.

Are Cylindrical Roller Bearings Suitable for Precision Applications?

Cylindrical roller bearings are suitable for precision applications, particularly when high radial or axial precision is required. Their ability to handle both types of loads with minimal play makes them valuable in precision machinery and equipment.

In conclusion, cylindrical roller bearings are integral components in various industrial applications across Europe. These FAQs aim to provide valuable insights into their features, benefits, and common applications. As we conclude this section, we encourage readers to explore the potential of cylindrical roller bearings in optimizing industrial processes and achieving greater efficiency.

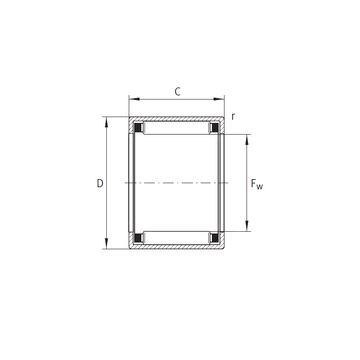

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

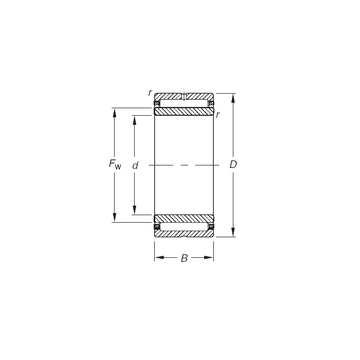

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

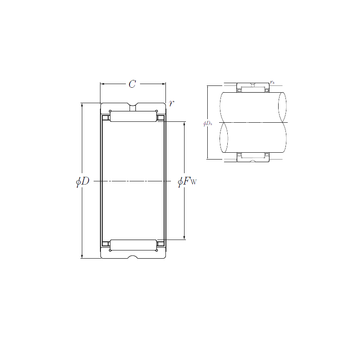

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

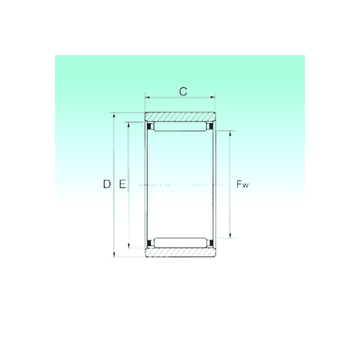

NK42/20R NTN Needle Roller Bearings