Home> Company News> Navigating Efficiency with Cylindrical Roller Thrust Bearings in Europe

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In the world of machinery and industrial applications, efficiency is a paramount concern. Every component plays a crucial role in achieving optimal performance, and one such component that often goes unnoticed but is vital for efficient operation is the cylindrical roller thrust bearing. In this article, titled "Navigating Efficiency with Cylindrical Roller Thrust Bearings in Europe," we will explore the significance of these bearings in various European industries and understand how they contribute to enhanced efficiency and precision.

Cylindrical roller thrust bearings are an essential part of many industrial machines and systems. They are designed to support axial loads and allow machinery to handle heavy thrust loads efficiently. These bearings are known for their high load-carrying capacity and exceptional durability, making them indispensable in applications where precise control and reliability are required.

As we delve deeper into this article, we will not only gain insights into the fundamental role of cylindrical roller thrust bearings but also discover their different types and configurations. We will explore how these bearings are designed and constructed to withstand axial forces and facilitate smooth operation. Additionally, we will highlight their unique features and advantages, showcasing why they are preferred in various machinery across Europe.

The journey through this article will take us from the basics of cylindrical roller thrust bearings to their intricate applications across a wide range of European industries. We will dive into real-world examples and case studies that demonstrate how these bearings have made a significant difference in achieving efficiency and precision. Their versatility and adaptability to the specific needs of European manufacturers will become evident as we explore their applications in various sectors.

This article will not only provide valuable information about cylindrical roller thrust bearings but also shed light on the latest innovations and technological advancements in this field. We will discuss how these innovations are shaping the industrial landscape in Europe and present case studies that exemplify innovative bearing applications.

Furthermore, we will address the challenges that European industries face when using cylindrical roller thrust bearings and provide practical solutions, best practices, and strategies for overcoming these challenges. Research and development play a crucial role in addressing bearing-related issues, and we will explore the advancements in this domain.

Sustainability and environmental impact are critical concerns in today's world, and our article will also examine how the manufacturing and usage of cylindrical roller thrust bearings affect the environment in Europe. We will highlight sustainable practices and initiatives within the bearing industry and emphasize the importance of eco-friendly bearing solutions.

In conclusion, "Navigating Efficiency with Cylindrical Roller Thrust Bearings in Europe" is a comprehensive exploration of the role of these bearings in achieving efficiency and precision across various European industries. This article will provide valuable insights for professionals, engineers, and manufacturers who rely on these bearings to navigate the complex world of machinery and industrial applications.

Understanding Cylindrical Roller Thrust Bearings

In our quest to navigate efficiency with cylindrical roller thrust bearings in Europe, it's essential to have a solid understanding of these remarkable components. This section will delve into the basics of cylindrical roller thrust bearings, elucidating their design, construction, and fundamental working principles. Additionally, we will explore the various types and configurations of these bearings and highlight their unique features and advantages within European industries.

Design and Construction:

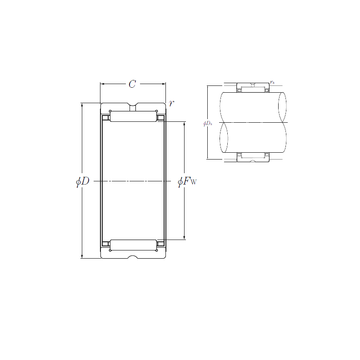

Cylindrical roller thrust bearings are engineered to withstand axial loads, making them invaluable in applications where machinery needs to handle heavy thrust loads efficiently. These bearings consist of two main components: cylindrical rollers and a raceway. The rollers are typically cylindrical in shape, and they are arranged parallel to the bearing axis. The raceway, on the other hand, provides the necessary support and guidance for the rollers.

One of the distinctive features of cylindrical roller thrust bearings is their high load-carrying capacity. They are designed to distribute axial loads evenly across the length of the rollers, allowing for efficient load-bearing without deformation. This design ensures optimal performance and long-lasting durability, even under challenging conditions.

Types and Configurations:

Cylindrical roller thrust bearings come in various types and configurations to cater to different industrial requirements. These types include single-direction bearings, double-direction bearings, and multi-direction bearings. Each type serves a specific purpose, and their selection depends on the application's axial load direction and magnitude.

- Single-direction bearings can accommodate axial loads in one direction and are commonly used in applications where thrust loads occur in a single direction.

- Double-direction bearings are capable of handling axial loads in both directions. They are ideal for applications where thrust forces can occur in either direction.

- Multi-direction bearings are designed to withstand axial loads from multiple directions, providing versatility in demanding industrial settings.

Unique Features and Advantages:

Cylindrical roller thrust bearings offer several unique features and advantages that make them preferred choices in European industries. Their inherent characteristics include:

|

Precision |

These bearings are known for their precision and accuracy in handling axial loads, ensuring minimal friction and efficient operation. |

|

High Load Capacity |

Cylindrical roller thrust bearings can support heavy axial loads, making them suitable for applications requiring robust load-bearing capabilities. |

|

Compact Design |

Their compact design allows for space-saving installations in machinery, making them adaptable to various industrial setups. |

|

Low Friction |

These bearings exhibit low friction properties, reducing energy consumption and enhancing overall efficiency. |

|

Durability |

With their robust construction and high-quality materials, cylindrical roller thrust bearings are designed to withstand challenging working conditions, ensuring a long service life. |

Understanding the design, construction, types, and advantages of cylindrical roller thrust bearings is crucial for appreciating their pivotal role in achieving efficiency and precision across European industries. As we continue our exploration, we will delve deeper into their real-world applications, showcasing how these bearings are making a difference in various industrial settings.

Applications Across European Industries

In our journey to understand the pivotal role of cylindrical roller thrust bearings in navigating efficiency across Europe, it's crucial to explore the vast landscape of industries and machinery where these bearings play an integral part in achieving performance and precision. This section will showcase the diverse range of European industries where cylindrical roller thrust bearings are indispensable, backed by real-world examples and case studies that highlight successful implementations. Additionally, we will emphasize the remarkable versatility of these bearings in meeting the specific needs of European manufacturers.

Automotive Industry:

One of the primary sectors where cylindrical roller thrust bearings find extensive application in Europe is the automotive industry. These precision bearings are utilized in transmissions, gearboxes, and engine components to efficiently handle axial loads and ensure smooth gear shifting and power transmission. Their high load-carrying capacity, precision, and durability make them essential for European automakers in producing reliable and high-performance vehicles.

A leading European automotive manufacturer incorporated cylindrical roller thrust bearings into their transmission systems, resulting in reduced friction, improved fuel efficiency, and enhanced overall vehicle performance.

Aerospace and Defense:

Europe boasts a robust aerospace and defense sector, and within this industry, cylindrical roller thrust bearings are employed in critical applications such as aircraft engines, landing gear systems, and missile guidance systems. These bearings offer the precision required for maintaining the structural integrity and performance of aerospace components under extreme conditions, including high-speed flight and varying loads.

A European defense contractor implemented cylindrical roller thrust bearings in their missile guidance systems, ensuring precise control and trajectory accuracy, thereby enhancing national security.

Renewable Energy:

The renewable energy sector in Europe heavily relies on cylindrical roller thrust bearings for wind turbine generators and solar tracking systems. These bearings assist in controlling the orientation of solar panels and wind turbine blades, optimizing energy capture and conversion. Their ability to handle both radial and axial loads ensures the efficient operation of renewable energy installations across Europe.

A European renewable energy company adopted cylindrical roller thrust bearings in their solar tracking systems, resulting in increased energy output and improved overall system efficiency.

Heavy Machinery and Industrial Equipment:

Across various European industries, including manufacturing, construction, and mining, cylindrical roller thrust bearings are a fundamental component of heavy machinery and industrial equipment. They are used in cranes, excavators, and conveyor systems to support heavy loads, enabling safe and efficient material handling and construction operations.

A European mining company integrated cylindrical roller thrust bearings into their excavators, resulting in enhanced load-bearing capacity, reduced maintenance downtime, and increased productivity.

Rail Transportation:

Europe's extensive rail transportation network relies on the precision and reliability of cylindrical roller thrust bearings. These bearings are vital in railcar couplings, bogies, and wheelsets, ensuring safe and smooth rail travel for passengers and freight. Their ability to handle axial loads in rail applications is paramount to the region's transportation infrastructure.

A European railway operator adopted cylindrical roller thrust bearings in their high-speed train wheelsets, improving stability, reducing friction, and enhancing passenger comfort.

Energy Generation and Transmission:

Cylindrical roller thrust bearings play a crucial role in energy generation and transmission facilities across Europe. They are used in turbine generators, pumps, and high-voltage transformers to handle axial loads and maintain equipment reliability. These bearings contribute to the uninterrupted supply of electricity to homes and industries.

A European power generation company integrated cylindrical roller thrust bearings into their turbine generators, resulting in improved load distribution and increased power output.

The applications of cylindrical roller thrust bearings across European industries are both diverse and indispensable. Their precision engineering, durability, and versatility contribute significantly to the efficiency and performance of machinery and equipment in various sectors. As we continue our exploration, we will delve into the innovations and advancements that are shaping the future of these bearings in Europe.

Innovations and Technological Advancements

As we journey through the world of cylindrical roller thrust bearings and their crucial role in enhancing efficiency across European industries, it's imperative to explore the latest innovations and technological advancements that are reshaping the industrial landscape. This section delves into cutting-edge developments in cylindrical roller thrust bearings, discusses their implications on European industries, and showcases real-world case studies and success stories related to innovative bearing applications.

Advanced Materials and Manufacturing Techniques:

Innovations in materials science and manufacturing techniques have paved the way for the development of cylindrical roller thrust bearings with enhanced properties. These bearings now incorporate advanced materials, such as high-performance polymers and superalloys, to improve load-carrying capacity, wear resistance, and overall durability. Cutting-edge manufacturing processes, including precision machining and 3D printing, have enabled the production of highly customized and intricately designed bearings.

A leading European bearing manufacturer successfully implemented 3D printing technology to produce intricate cylindrical roller thrust bearings for specialized aerospace applications. The result was reduced weight, increased load capacity, and improved fuel efficiency in aircraft.

2. Miniaturization and Microtechnology:

The demand for miniaturized and highly precise cylindrical roller thrust bearings has led to significant advancements in microtechnology. These miniature bearings are now employed in precision instruments, medical devices, and robotics, where space constraints and precision are critical. Microfabrication techniques, such as photolithography and microelectromechanical systems (MEMS), have enabled the production of sub-millimeter-sized bearings with exceptional performance.

A European medical device manufacturer utilized microfabrication techniques to create miniature cylindrical roller thrust bearings for use in surgical robots. These bearings contributed to the precision and stability of the robotic surgical procedures.

IoT and Predictive Maintenance:

The integration of the Internet of Things (IoT) and data analytics has revolutionized maintenance practices for cylindrical roller thrust bearings in Europe. Smart sensors embedded within bearings collect real-time data on operating conditions, load distribution, and wear patterns. This data is transmitted to a central system, enabling predictive maintenance strategies. By predicting bearing failures before they occur, European industries can significantly reduce downtime and maintenance costs.

A European industrial plant implemented IoT-enabled cylindrical roller thrust bearings in their conveyor systems. Predictive maintenance based on sensor data led to a 30% reduction in unplanned downtime and a substantial increase in operational efficiency.

Lubrication and Coating Technologies:

Innovations in lubrication and coating technologies have improved the performance and longevity of cylindrical roller thrust bearings. Advanced lubricants with high temperature resistance and superior anti-wear properties have extended bearing service life in high-heat applications. Furthermore, nano-coatings and surface treatments have reduced friction, minimized wear, and enhanced corrosion resistance.

A European steel manufacturing company adopted specialized lubrication and coating technologies in their industrial furnace's bearings, resulting in extended bearing life and reduced maintenance frequency.

Sustainable Bearings: Environmental Impact Mitigation:

In response to environmental concerns, European bearing manufacturers have been actively engaged in developing sustainable bearing solutions. This includes the use of eco-friendly materials, recyclability, and reduced energy consumption during manufacturing. These innovations not only align with global sustainability goals but also appeal to environmentally conscious industries.

A European wind turbine manufacturer incorporated sustainable cylindrical roller thrust bearings in their turbine gearboxes, reducing the environmental footprint of wind energy production.

The ongoing innovations and technological advancements in cylindrical roller thrust bearings are transforming the European industrial landscape. These developments not only improve bearing performance but also contribute to the overall efficiency, reliability, and sustainability of industries across Europe. As we conclude our exploration, we will reflect on the challenges faced by European manufacturers in harnessing the full potential of these innovative bearings and the solutions to overcome them.

Challenges and Solutions

In our exploration of the remarkable world of cylindrical roller thrust bearings and their integral role in enhancing efficiency across European industries, it's vital to acknowledge the challenges that European manufacturers and industries encounter when employing these precision components.

Load Variability and Shock Loads:

Challenge: European industries often contend with fluctuating loads and occasional shock loads, which can put substantial stress on cylindrical roller thrust bearings. These unpredictable conditions can lead to premature bearing failure and increased maintenance costs.

To mitigate this challenge, European manufacturers employ bearings with robust designs, incorporating advanced materials and heat treatments. Additionally, predictive maintenance practices, such as regular inspections and monitoring, help detect early signs of stress and facilitate timely replacements.

Lubrication and Contamination:

Challenge: Proper lubrication is critical for the optimal performance of cylindrical roller thrust bearings. However, European industries may encounter challenges in maintaining consistent lubrication levels and preventing contamination, which can lead to increased friction and wear.

European manufacturers employ automated lubrication systems that ensure a steady supply of lubricant to bearings. Moreover, protective seals and labyrinth designs are utilized to safeguard against contamination from dust, debris, and moisture, ensuring the longevity of bearings.

Temperature Extremes:

Challenge: European industries often operate in environments with extreme temperature variations. Cylindrical roller thrust bearings must function optimally under both high-temperature and low-temperature conditions.

Bearings with specialized heat-resistant materials and coatings are employed to ensure reliable performance in extreme temperatures. European manufacturers also implement temperature monitoring systems to detect overheating and take preventive measures.

Alignment and Installation Errors:

Challenge: Improper alignment and installation can result in misalignment and excessive axial loads on cylindrical roller thrust bearings, leading to premature wear and failure.

European industries adhere to strict alignment and installation procedures, including precision measurements and alignment tools. Employee training programs are often implemented to ensure proper handling and installation of bearings, reducing the risk of errors.

Research and Development Initiatives:

Challenge: Continuous improvement and innovation are essential in addressing the evolving challenges related to cylindrical roller thrust bearings. European industries require access to cutting-edge R&D initiatives to stay at the forefront of bearing technology.

European manufacturers actively invest in R&D programs and collaborations with academic institutions to advance bearing technology. These initiatives focus on materials science, lubrication techniques, and bearing design to develop solutions that meet the evolving demands of industries.

Industry-Specific Challenges:

Challenge: Different industries within Europe may face unique challenges when utilizing cylindrical roller thrust bearings. These challenges can range from stringent regulatory requirements to specific performance criteria.

European bearing manufacturers tailor solutions to address industry-specific challenges. Collaborations with industry experts and the customization of bearing designs ensure that these precision components meet the exacting standards of various sectors.

In conclusion, while the utilization of cylindrical roller thrust bearings offers substantial benefits in enhancing efficiency and precision across European industries, it is crucial to acknowledge and address the challenges that may arise. Through innovative solutions, best practices, and a commitment to research and development, European manufacturers and industries can navigate these challenges successfully. As we conclude our journey through the world of cylindrical roller thrust bearings in Europe, we will reflect on the profound impact of these bearings on the industrial landscape and their role in driving efficiency and excellence.

Sustainability and Environmental Impact

As we navigate the realm of cylindrical roller thrust bearings and their pivotal role in enhancing efficiency across Europe, it's equally essential to address the environmental impact of these precision components. This section dives into the environmental considerations associated with the manufacturing and usage of cylindrical roller thrust bearings, emphasizes sustainable practices within the bearing industry, and underscores the importance of eco-friendly bearing solutions in our contemporary world.

Environmental Impact of Manufacturing:

Cylindrical roller thrust bearings, like any industrial product, undergo manufacturing processes that can have environmental consequences. However, European bearing manufacturers are actively adopting sustainable practices to mitigate these impacts. Here are key aspects to consider:

- Materials Selection: European manufacturers prioritize the use of environmentally friendly materials, including recyclable and biodegradable options, in bearing production.

- Energy Efficiency: Sustainable manufacturing involves reducing energy consumption during production. Manufacturers are implementing energy-efficient technologies and optimizing processes to minimize their carbon footprint.

- Waste Reduction: Waste minimization is a critical focus. Manufacturers aim to reduce material waste and implement recycling programs for scrap materials generated during production.

Usage and Environmental Responsibility:

Beyond the manufacturing phase, the usage of cylindrical roller thrust bearings also plays a role in environmental impact. European industries are actively working to ensure responsible use:

- Longevity and Durability: Bearings designed for longevity reduce the frequency of replacements, which, in turn, reduces waste and energy consumption associated with manufacturing new bearings.

- Lubrication Efficiency: Proper lubrication reduces friction, which results in energy savings and a longer lifespan for bearings. European industries prioritize efficient lubrication practices.

- Maintenance and Lifecycle Management: European manufacturers and industries employ proactive maintenance strategies to extend bearing lifecycles, reducing the need for premature replacements.

Sustainable Initiatives within the Bearing Industry:

The bearing industry in Europe is taking significant strides toward sustainability. Here are some notable initiatives:

|

Recycling Programs |

Manufacturers are setting up bearing recycling programs to recover and reuse materials from discarded or replaced bearings |

|

Eco-Friendly Lubricants |

The development and use of environmentally friendly lubricants are gaining traction, reducing the environmental impact of bearing maintenance. |

|

Green Certification |

European bearing manufacturers are pursuing green certifications to validate their commitment to sustainability. |

The Significance of Eco-Friendly Bearing Solutions:

In today's environmentally conscious world, the significance of eco-friendly bearing solutions cannot be overstated. These solutions align with the broader goals of sustainability, responsible manufacturing, and reduced environmental impact. Here are the key takeaways:

- Reduced Carbon Footprint: Eco-friendly bearings contribute to a lower carbon footprint by minimizing the environmental impact of manufacturing and usage.

- Cost Savings: Sustainable practices often lead to cost savings in the long run, benefiting both manufacturers and end-users.

- Market Competitiveness: Companies adopting sustainable bearing solutions enhance their competitiveness in the market, meeting the demands of environmentally conscious consumers and regulatory requirements.

In conclusion, sustainability is not just a buzzword in the bearing industry; it's a driving force shaping the future. European manufacturers and industries are embracing eco-friendly practices, reducing their environmental footprint, and paving the way for a more sustainable future. As we wrap up our journey through the world of cylindrical roller thrust bearings in Europe, we reflect on the holistic impact of these bearings, not only on efficiency and performance but also on our planet's well-being.

Conclusion

In conclusion, our exploration into the world of cylindrical roller thrust bearings and their impact on efficiency across European industries has revealed their pivotal role in ensuring precision and performance. This concluding section aims to summarize the key takeaways from our journey, emphasizing the vital role these bearings play and shedding light on the promising future they hold in Europe's industrial landscape.

Enhancing Efficiency:

Cylindrical roller thrust bearings have emerged as unsung heroes in the realm of European industries. Their design, construction, and working principles were dissected in our journey, highlighting their ability to withstand heavy axial loads while maintaining optimal efficiency. This attribute alone has made them indispensable in various machinery and applications across Europe.

Diverse Applications:

Our exploration delved into the wide range of European industries where cylindrical roller thrust bearings find their home. From automotive manufacturing to aerospace engineering, these bearings have left their mark by ensuring machinery operates with precision, contributing to the overall efficiency of the European industrial sector.

Innovations and Sustainability:

We also discussed the latest innovations and technological advancements in the world of cylindrical roller thrust bearings. These innovations are reshaping the industrial landscape in Europe, driving companies to adopt eco-friendly and sustainable practices. As the bearing industry evolves, it continues to align with the broader goals of sustainability and environmental responsibility.

Challenges and Solutions:

Our journey highlighted that with great efficiency comes the need to address challenges. European industries have identified common hurdles associated with cylindrical roller thrust bearings, but they've also provided solutions and best practices to overcome these challenges. Furthermore, research and development play a significant role in continually improving bearing-related solutions.

A Promising Future:

As we conclude, it's clear that cylindrical roller thrust bearings are not merely components; they are enablers of efficiency, precision, and sustainability. Their role in European industries is set to grow as innovation and sustainable practices take center stage. These bearings are poised to continue their journey as integral parts of machinery, supporting European manufacturers in their pursuit of excellence.

In the grand tapestry of Europe's industrial landscape, cylindrical roller thrust bearings are the threads that bind efficiency and performance. With this, we conclude our exploration, knowing that these bearings will remain indispensable in shaping the future of European industries.

FAQs: Common Questions About Cylindrical Roller Thrust Bearings

we will address some common questions regarding cylindrical roller thrust bearings. These frequently asked questions aim to provide a better understanding of these crucial components and their significance in enhancing efficiency across various European industries.

What Are Cylindrical Roller Thrust Bearings?

Cylindrical roller thrust bearings are specialized types of rolling element bearings designed to handle axial loads in a single direction. They play a pivotal role in various industrial applications across Europe, ensuring optimal efficiency and precision.

How Do Cylindrical Roller Thrust Bearings Operate?

Cylindrical roller thrust bearings operate by utilizing cylindrical rollers that transmit axial force along their axis. When subjected to axial loads, these rollers rotate, allowing for controlled motion in the axial direction. This mechanism ensures even distribution of the load, reducing wear and tear.

What Are the Different Types of Cylindrical Roller Thrust Bearings?

Cylindrical roller thrust bearings come in several types and configurations, including single direction and double direction bearings. Single direction bearings handle axial loads in one direction, while double direction bearings can accommodate axial loads in both directions. The choice depends on specific application requirements.

Where Are Cylindrical Roller Thrust Bearings Utilized?

These bearings find application in a wide array of European industries, including automotive manufacturing, aerospace engineering, heavy machinery, and more. They are essential in machinery that demands precision, efficiency, and the capability to withstand axial loads.

What Are the Advantages of Cylindrical Roller Thrust Bearings?

Cylindrical roller thrust bearings offer numerous advantages, such as high load-carrying capacity, precise axial control, and the ability to operate at high speeds. Their design minimizes friction, leading to reduced energy consumption and heat generation.

How Can I Select the Right Cylindrical Roller Thrust Bearing for My Application?

Selecting the appropriate bearing involves considering factors like load capacity, speed, lubrication, and environmental conditions. Consulting experts or referring to bearing manufacturers' guidelines can help make an informed choice.

Are Cylindrical Roller Thrust Bearings Environmentally Friendly?

Cylindrical roller thrust bearings are designed with efficiency in mind, often resulting in lower energy consumption and reduced environmental impact. Furthermore, the bearing industry is continually promoting eco-friendly and sustainable practices.

Can Cylindrical Roller Thrust Bearings Handle Extreme Conditions?

These bearings are known for their robustness, making them suitable for demanding conditions. However, it's crucial to select bearings designed to withstand specific environmental challenges, such as high temperatures or corrosive atmospheres.

What Lies in the Future for Cylindrical Roller Thrust Bearings in Europe?

As Europe continues to prioritize industrial efficiency and sustainability, the future of cylindrical roller thrust bearings appears promising. Ongoing innovations in bearing technology and a growing focus on eco-friendly practices ensure that these bearings will play a pivotal role in Europe's industrial landscape.

Where Can I Source Quality Cylindrical Roller Thrust Bearings in Europe?

Quality cylindrical roller thrust bearings are available through reputable bearing manufacturers and distributors across Europe. It is advisable to collaborate with trusted suppliers who offer a wide range of bearing solutions and provide expert guidance based on your specific needs.

In conclusion, cylindrical roller thrust bearings are indispensable components that drive efficiency and precision across various European industries. These FAQs aim to clarify their functionality, applications, benefits, and future prospects. As we conclude our exploration, we encourage readers to delve further into the world of cylindrical roller thrust bearings and harness their potential for enhancing efficiency in Europe's industrial landscape.

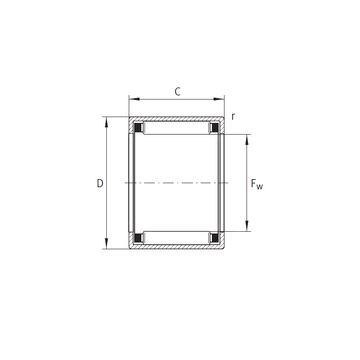

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

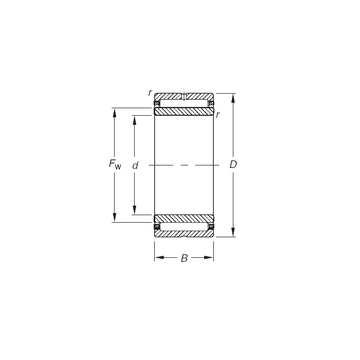

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

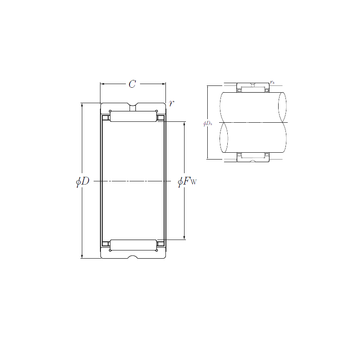

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

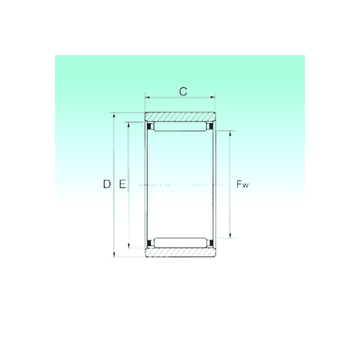

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings