Home> Company News> Rexroth is a leading manufacturer of hydraulic systems.

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Hydraulic systems are an essential component in many industrial applications, providing power and control for various machines and equipment. One of the leading manufacturers of hydraulic systems is Rexroth, a company with a long history and reputation for producing high-quality products. In this article, we will explore the history and overview of Rexroth hydraulic systems, the advantages of using them, their key components, applications, and maintenance and troubleshooting tips. Whether you're in the aerospace, agricultural, construction, marine, mining, or renewable energy industry, understanding the benefits of Rexroth hydraulic systems can help you make an informed decision about your hydraulic system needs.

History and Overview of Rexroth Hydraulic Systems

Rexroth is a leading manufacturer of hydraulic systems, serving various industries such as aerospace, construction, mining, and renewable energy. The company was founded in 1795 in Germany and has since expanded its operations globally. Today, it is a subsidiary of the Bosch Group and operates as Bosch Rexroth, a major supplier of drive and control technologies.

Rexroth's product line includes hydraulic pumps, motors, cylinders, valves, filters, and electronic controls. Their products are designed to meet the demands of various applications, ranging from simple to complex systems. One of the unique features of Rexroth hydraulic systems is their ability to integrate with different technologies, providing solutions for advanced automation and control.

The company's hydraulic products are designed to provide high performance, energy efficiency, and reliability. Rexroth's hydraulic pumps, for instance, are known for their precise control and low noise emissions. Their valves are designed to maintain consistent pressure and flow rates, making them ideal for industrial applications that require precise control.

In addition to their standard product line, Rexroth also offers customized solutions tailored to meet specific customer needs. Their team of engineers and technicians work closely with customers to understand their requirements and design hydraulic systems that meet their unique needs. With their experience and expertise, Rexroth has become a trusted partner for many industries and applications that require hydraulic solutions.

Advantages of Rexroth Hydraulic Systems

Rexroth is a leading manufacturer of hydraulic systems with a rich history dating back to the early 1900s. The company has established itself as a leader in the field of hydraulic systems due to its focus on innovation and advanced technology. Hydraulic systems are essential in many industrial applications, and Rexroth is at the forefront of producing high-quality systems that meet the needs of its clients.

Rexroth has its roots in Germany, where it was founded in 1904 by Gottlieb Daimler and Wilhelm Maybach. The company started as a manufacturer of engines and quickly expanded its operations to include hydraulic systems. Today, Rexroth is a global company with operations in over 80 countries, providing cutting-edge hydraulic systems to clients across the world.

Rexroth hydraulic systems are designed to provide superior performance, reliability, and durability. The company's products range from pumps, valves, and cylinders to electronic controllers and filters. These components work together seamlessly to ensure maximum efficiency and energy savings while reducing maintenance and downtime.

One of the unique features of Rexroth hydraulic systems is their focus on sustainability and environmental friendliness. The company's products are designed to reduce energy consumption and carbon footprint while providing optimal performance.

Overall, Rexroth hydraulic systems offer several advantages over other hydraulic systems. Their high efficiency and energy savings result in reduced operating costs, while their durability and reliability ensure a long service life with minimal maintenance. Rexroth hydraulic systems are also compatible with various applications, making them ideal for use in industries such as aerospace, agriculture, construction, marine and offshore, mining, and renewable energy.

In the next section, we will discuss in detail the advantages of using Rexroth hydraulic systems.

Key Components of Rexroth Hydraulic Systems

Rexroth hydraulic systems are comprised of several key components that work together to deliver high-performance and reliable operation. These components include:

-

Pumps: Rexroth offers a range of hydraulic pumps, including axial piston pumps, radial piston pumps, and vane pumps. These pumps are designed to deliver high efficiency and reliability, while also offering low noise levels and reduced emissions.

-

Valves: Rexroth hydraulic valves are designed to control the flow of hydraulic fluid, allowing for precise operation and control. They offer a wide range of valves, including directional control valves, pressure control valves, and flow control valves.

-

Cylinders: Rexroth hydraulic cylinders are used to provide linear motion in hydraulic systems. They offer a range of cylinders, including tie-rod cylinders, welded cylinders, and mill-type cylinders.

-

Filters: Rexroth hydraulic filters are used to remove contaminants from hydraulic fluid, ensuring reliable operation and reduced maintenance. They offer a range of filters, including suction filters, pressure filters, and return line filters.

-

Electronic controllers: Rexroth offers advanced electronic controllers that allow for precise control and operation of hydraulic systems. These controllers are designed to optimize performance, reduce energy consumption, and improve system reliability.

Rexroth's commitment to research and development has led to the creation of these advanced components, which are designed to meet the needs of various industrial applications.

Applications of Rexroth Hydraulic Systems

Rexroth hydraulic systems are used in a wide range of industrial applications, including:

-

Aerospace industry: Rexroth hydraulic systems are used in the aerospace industry for various applications, including landing gear systems, flight control systems, and engine controls.

-

Agricultural equipment: Rexroth hydraulic systems are used in agricultural equipment, including tractors, harvesters, and irrigation systems.

-

Construction machinery: Rexroth hydraulic systems are used in construction machinery, including excavators, bulldozers, and cranes.

-

Marine and offshore applications: Rexroth hydraulic systems are used in marine and offshore applications, including ship steering systems, winches, and cranes.

-

Mining industry: Rexroth hydraulic systems are used in the mining industry for various applications, including mining equipment, conveyor systems, and hydraulic shovels.

-

Renewable energy: Rexroth hydraulic systems are used in renewable energy applications, including wind turbines and hydroelectric power plants.

Rexroth hydraulic systems are versatile and can be customized to meet the needs of various industrial applications. The company's commitment to innovation and research ensures that their products are at the forefront of hydraulic technology, delivering high efficiency, reliability, and performance.

Maintenance and Troubleshooting of Rexroth Hydraulic Systems

Proper maintenance and inspection are essential to keep hydraulic systems running smoothly and prevent breakdowns. Rexroth hydraulic systems are known for their durability and reliability, but regular maintenance is still necessary to ensure optimal performance. Here are some best practices for maintaining and troubleshooting Rexroth hydraulic systems:

Regular Maintenance

-

Follow the manufacturer's recommended maintenance schedule: Rexroth provides specific guidelines on when to perform routine maintenance tasks, such as oil changes, filter replacements, and inspections. Following these recommendations will help extend the life of the system and prevent unexpected downtime.

-

Keep the system clean: Dirt and debris can cause damage to hydraulic components, so it's important to keep the system clean. Regularly inspect and clean the reservoir, filters, and other components to ensure they are free of contaminants.

-

Check fluid levels and quality: Hydraulic fluid levels should be checked regularly and topped off as needed. It's also important to monitor the quality of the fluid and replace it when necessary to prevent damage to the system.

-

Inspect hoses and connections: Hoses and connections should be checked for signs of wear or damage, such as cracks, leaks, or corrosion. Replace any damaged parts to prevent leaks or failure.

-

Perform system testing: Regularly testing the system can help identify potential issues before they become major problems. Test the system for leaks, pressure drops, and other performance issues.

Troubleshooting Common Issues

-

Low fluid levels: If the hydraulic system is low on fluid, it can cause a range of issues, such as slow operation or component failure. Check the fluid levels and top off as needed.

-

Contaminated fluid: Dirty or contaminated hydraulic fluid can cause component failure or reduce the efficiency of the system. Check the fluid quality and replace if necessary.

-

Leaks: Hydraulic leaks can cause a loss of pressure or fluid, which can lead to component failure. Check for leaks in hoses, connections, and other components, and replace any damaged parts.

-

Overheating: Overheating can cause damage to hydraulic components, leading to failure or reduced performance. Check for signs of overheating, such as discolored fluid or hot components, and address the issue immediately.

-

Slow operation: If the system is operating slowly or not at all, it could be due to low fluid levels, clogged filters, or other issues. Perform a system inspection to identify the root cause and take appropriate action.

By following these best practices for maintenance and troubleshooting, Rexroth hydraulic systems can provide reliable and efficient performance for years to come.

Conclusion

Rexroth hydraulic systems have proven to be a reliable and efficient solution for various industrial applications. The benefits and features of Rexroth hydraulic systems make them a popular choice for businesses and industries worldwide.

In conclusion, Rexroth hydraulic systems are a top choice for those in need of a durable, reliable, and energy-efficient hydraulic system. With a history of innovation and superior quality, Rexroth continues to be a leading manufacturer of hydraulic systems in the industry. From aerospace to renewable energy, Rexroth hydraulic systems are compatible with various applications and offer numerous advantages over other hydraulic systems. It is important to consider the key components of a Rexroth hydraulic system and to follow proper maintenance and troubleshooting procedures to ensure optimal performance and longevity. For those considering a hydraulic system for their business or application, Rexroth hydraulic systems are a proven solution that can improve efficiency, reduce downtime, and increase profitability.

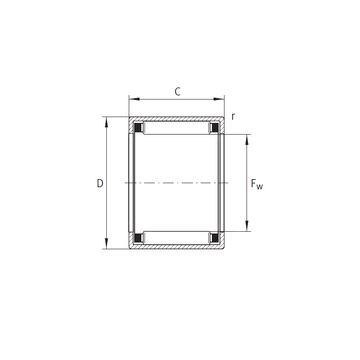

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

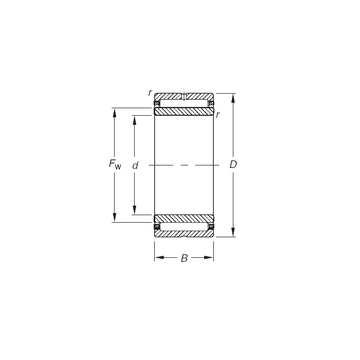

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

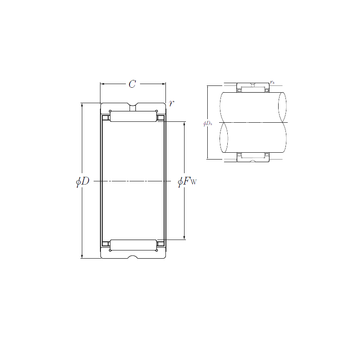

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

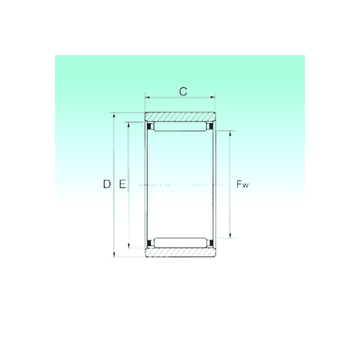

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings