Home> Company News> How A Pressure Compensating Flow Control Valve Works

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Hydraulic systems require precise control over flow rate and pressure to function efficiently, making flow control valves essential components. Pressure compensating flow control valves are particularly important because they regulate flow rate regardless of pressure changes. In this article, we will discuss the principles and benefits of pressure compensating flow control valves, their installation and maintenance, and how they compare to other types of flow control valves.

Pressure compensating flow control valves are essential in hydraulic systems because they ensure that the flow rate remains constant despite pressure changes. This is particularly important in systems where precise control is required, such as in manufacturing, construction, and material handling equipment. Understanding how these valves work and their advantages can help in selecting the right valve for a particular application.

Understanding Pressure Compensating Flow Control Valve

Hydraulic systems often require precise control over the flow rate to ensure efficient and effective operation. One important component that helps achieve this control is the pressure compensating flow control valve.

A pressure compensating flow control valve is a type of valve used in hydraulic systems to regulate the flow rate of fluids. It is designed to maintain a constant flow rate despite changes in pressure or load. The valve works by adjusting its opening to regulate the fluid flow, depending on the pressure or load on the system.

The main function of the pressure compensating flow control valve is to ensure that the hydraulic system operates at a constant flow rate. It does this by adjusting the valve opening to compensate for changes in pressure, ensuring that the flow rate remains consistent even as the load on the system changes.

The pressure compensating flow control valve is made up of several components and parts that work together to regulate the flow of fluid in the system. These components include a valve body, spool, spring, adjustment screw, and hydraulic connections.

The valve body is the outer casing that contains the other components of the valve. The spool is a movable part of the valve that regulates the flow of fluid through the valve. The spring helps to hold the spool in position and provides the necessary force for the valve to open and close. The adjustment screw allows the user to adjust the valve's opening, while the hydraulic connections allow the fluid to flow through the valve and into the hydraulic system.

Understanding the pressure compensating flow control valve and its main function is important for ensuring that hydraulic systems operate efficiently and effectively. By regulating the flow rate of fluids and compensating for changes in pressure or load, the valve helps maintain the desired performance of the hydraulic system.

Working Principles of Pressure Compensating Flow Control Valve

Pressure compensating flow control valves are designed to regulate the flow of fluid in hydraulic systems. They work by maintaining a constant flow rate regardless of pressure changes within the system. This is achieved through the use of a pressure compensator, which senses the pressure drop across the valve and adjusts the valve's opening to maintain a constant flow rate.

There are two main types of pressure compensating flow control valves: spool valves and poppet valves. Spool valves have a spool that moves back and forth inside a valve body, controlling the flow of fluid through the valve. Poppet valves use a poppet, which is a disc-shaped component that moves up and down inside the valve body to control fluid flow.

The pressure compensator in a pressure compensating flow control valve is typically a spring-loaded piston that is exposed to system pressure on one side and a reference pressure on the other. The piston moves in response to changes in pressure and acts to control the opening of the valve, allowing fluid to flow through at a constant rate.

The valve's operation is affected by both pressure and temperature. As the pressure in the system changes, the valve compensates by adjusting its opening to maintain a constant flow rate. Changes in temperature can also affect the valve's operation, as the viscosity of the fluid can change with temperature.

Overall, pressure compensating flow control valves are essential components in hydraulic systems, ensuring that fluid flows at a constant rate regardless of changes in pressure or temperature. Understanding the working principles of these valves is important for selecting the right valve for a specific application and ensuring optimal system performance.

Benefits of Using a Pressure Compensating Flow Control Valve

A pressure compensating flow control valve has several advantages over other types of flow control valves. Below are some of the benefits of using a pressure compensating flow control valve in your hydraulic system:

-

Maintains Constant Flow Rate: One of the main benefits of using a pressure compensating flow control valve is that it maintains a constant flow rate. This is important because variations in flow rate can cause problems such as overheating, which can damage the hydraulic system components.

-

Accurate Flow Control: Pressure compensating flow control valves provide accurate flow control, making them ideal for applications that require precise control over flow rates. These valves are often used in industrial settings where precise control over flow rates is necessary.

-

Improved Efficiency: Pressure compensating flow control valves help improve the efficiency of hydraulic systems. By maintaining a constant flow rate, these valves help reduce energy consumption and extend the life of hydraulic system components.

-

Lower Maintenance Costs: Using a pressure compensating flow control valve can help reduce maintenance costs. Because these valves help reduce wear and tear on hydraulic system components, the need for maintenance and repairs is reduced.

-

Wide Range of Applications: Pressure compensating flow control valves are used in a wide range of applications, including agriculture, construction, and manufacturing. They are often used in hydraulic systems that require precise control over flow rates.

-

More Reliable: Pressure compensating flow control valves are more reliable than other types of flow control valves. They are less likely to fail or malfunction, which helps reduce downtime and maintenance costs.

Overall, using a pressure compensating flow control valve in your hydraulic system can provide several benefits, including improved efficiency, accuracy, and reliability. By maintaining a constant flow rate and reducing wear and tear on hydraulic system components, these valves can help reduce energy consumption and maintenance costs while extending the life of your hydraulic system.

Installation and Maintenance of Pressure Compensating Flow Control Valve

Once you have chosen the appropriate pressure compensating flow control valve for your hydraulic system, it is important to properly install and maintain the valve to ensure optimal performance and longevity. Here are some steps to follow for installation and maintenance:

Installation

- Before installing the valve, ensure that it is compatible with your system's pressure, flow rate, and temperature requirements.

- Select the appropriate valve size and type for your application.

- Install the valve in the correct orientation and direction of flow. The valve should be installed in a position that allows for easy access and maintenance.

- Connect the valve to the hydraulic system using appropriate fittings and hoses.

- Ensure that all connections are tight and secure, and that there are no leaks in the system.

- Adjust the valve's setting according to your system's requirements.

Maintenance

- Follow the manufacturer's recommended maintenance schedule for the valve.

- Regularly inspect the valve for any signs of damage or wear, such as leaks or corrosion.

- Clean the valve regularly to prevent debris from building up and affecting performance.

- Replace any damaged or worn parts as soon as possible to avoid further damage to the valve or the hydraulic system.

- If the valve is not functioning correctly, troubleshoot the problem and address it promptly to prevent further damage.

Proper installation and maintenance of the pressure compensating flow control valve will ensure that it operates correctly and efficiently, improving the performance and lifespan of your hydraulic system.

Comparison to Other Flow Control Valves

There are several types of flow control valves, each with its own set of advantages and disadvantages. In this section, we will compare pressure compensating flow control valves to other commonly used flow control valves and highlight the differences.

Throttle Valves

Throttle valves are the most basic type of flow control valve, regulating fluid flow by constricting the flow path. They are typically used in low-pressure systems and are not very precise. Throttle valves are prone to overheating and can cause energy loss due to pressure drop.

In contrast, pressure compensating flow control valves are much more efficient and precise. They maintain a constant flow rate despite changes in system pressure and temperature, making them ideal for high-pressure systems. Additionally, pressure compensating flow control valves are less prone to overheating and do not cause significant pressure drops.

Needle Valves

Needle valves are similar to throttle valves, but they provide greater control over flow rate. They are commonly used in low-flow systems and are not recommended for high-pressure applications.

Pressure compensating flow control valves offer better precision and control over flow rate than needle valves. They also maintain a constant flow rate, making them more suitable for high-pressure systems.

Flow Divider Valves

Flow divider valves are used to divide fluid flow into two or more paths. They are commonly used in hydraulic systems where multiple actuators need to be controlled independently.

Pressure compensating flow control valves can be used as flow divider valves, providing precise control over each actuator's flow rate. However, flow divider valves are typically more efficient at dividing flow than pressure compensating flow control valves.

Proportional Valves

Proportional valves are used to regulate flow rate proportionally to an input signal. They are commonly used in closed-loop control systems and are highly precise.

Pressure compensating flow control valves can be used as proportional valves, but they are not as precise as dedicated proportional valves. However, pressure compensating flow control valves have the advantage of maintaining a constant flow rate despite changes in system pressure and temperature.

Conclusion

Pressure compensating flow control valves are an essential component in hydraulic systems, ensuring precise control of flow rate and increased efficiency. Understanding the benefits and working principles of this valve can help in selecting the right valve for a particular application.

In conclusion, pressure compensating flow control valves are a valuable addition to any hydraulic system. These valves provide constant flow rates even in the presence of pressure fluctuations, improving the overall efficiency and performance of the system. They offer several advantages over other flow control valves, including improved accuracy, consistency, and reliability. Proper installation and maintenance procedures can ensure the longevity and effectiveness of these valves. When selecting a pressure compensating flow control valve, it is essential to consider factors such as load capacity, temperature and environmental conditions, installation requirements, and power source compatibility. Consulting with a hydraulic expert or manufacturer can provide valuable insights and recommendations for selecting the appropriate valve for a particular application.

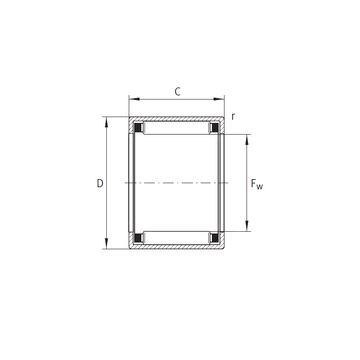

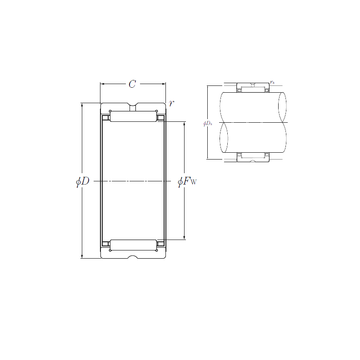

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

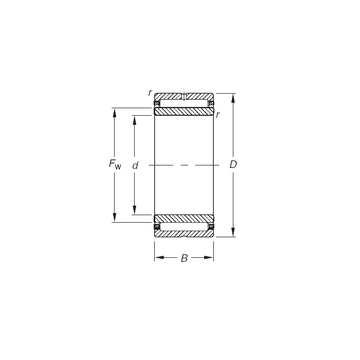

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

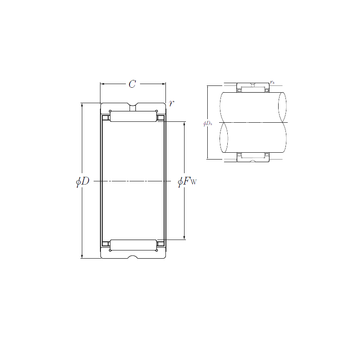

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

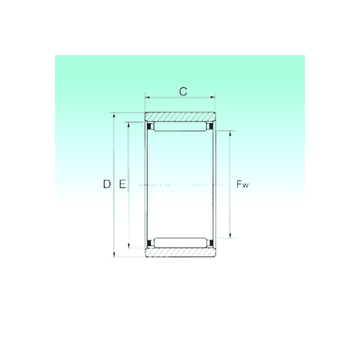

NK42/20R NTN Needle Roller Bearings