Home> Company News> Excavator Hydraulic Pump Kawasaki KX60

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

In the construction industry, hydraulic systems are essential components of heavy machinery like excavators, cranes, bulldozers, and others. One of the critical components in hydraulic systems is the hydraulic pump, which powers the hydraulic system and enables it to perform the required tasks. In this article, we will focus on the Kobelco excavator hydraulic pump, a critical component of the Kobelco excavator. We will discuss the importance of hydraulic pumps in heavy machinery, the Kobelco excavator hydraulic pump's features, and its maintenance requirements.

Kobelco is one of the leading manufacturers of hydraulic systems and heavy machinery in the market. Their excavators are known for their reliability, durability, and high performance. The hydraulic pump is a crucial component of the Kobelco excavator, enabling it to perform various tasks like digging, lifting, and moving materials.

In the following sections, we will discuss the Kobelco excavator hydraulic pump in detail, including its features, benefits, and maintenance requirements.

Kawasaki KX60 Excavator Hydraulic Pump Features

The Kawasaki KX60 excavator hydraulic pump is a variable displacement pump that is designed to provide the required hydraulic flow and pressure to power different excavator attachments. The pump's variable displacement design enables it to adjust the flow and pressure of the hydraulic fluid based on the requirements of the excavator attachments being used. This ensures that the excavator can perform various tasks with precision and control, from digging and lifting to loading and hauling.

One of the key features of the Kawasaki KX60 excavator hydraulic pump is its ability to maintain a consistent flow and pressure, even under heavy loads. This is essential for ensuring that the hydraulic system operates efficiently and effectively. The pump is also equipped with a pressure relief valve, which protects the hydraulic system from damage in case of overload or system malfunction.

Another important feature of the Kawasaki KX60 excavator hydraulic pump is its built-in filtration system. The filtration system ensures that the hydraulic fluid is clean and free of contaminants, which helps to reduce wear and tear on the hydraulic system and enhance its performance and efficiency.

Overall, the Kawasaki KX60 excavator hydraulic pump is designed to provide reliable and efficient performance for various excavation tasks. Its variable displacement design, pressure relief valve, and filtration system make it a popular choice for excavator operators who demand precise control and high performance from their hydraulic systems.

Benefits of the Kawasaki KX60 Excavator Hydraulic Pump

The Kawasaki KX60 excavator hydraulic pump offers various benefits to excavator operators. One of the main advantages is its variable displacement design, which allows for precise control of the hydraulic flow and pressure. This feature enables the pump to provide the required hydraulic power to operate different excavator attachments efficiently.

The pressure relief valve is another essential feature of the Kawasaki KX60 excavator hydraulic pump. The valve protects the hydraulic system from damage in case of overload or malfunction, extending the life of the pump and other hydraulic components. The pressure relief valve ensures that the pump operates within safe pressure limits, preventing the hydraulic system from being damaged due to excess pressure.

The built-in filtration system is also an important benefit of the Kawasaki KX60 excavator hydraulic pump. The filtration system ensures that the hydraulic fluid is clean, free of contaminants, and properly lubricated. The clean hydraulic fluid reduces wear and tear on the hydraulic system, enhancing its performance and efficiency. The filtration system also prolongs the life of the hydraulic system by preventing damage from contaminated hydraulic fluid.

In summary, the Kawasaki KX60 excavator hydraulic pump's variable displacement design, pressure relief valve, and built-in filtration system offer various benefits that make it a reliable and efficient option for powering excavator attachments. The pump provides precise hydraulic power, protecting the hydraulic system from damage and ensuring that the hydraulic fluid is clean, properly lubricated, and free of contaminants.

Kawasaki KX60 Excavator Hydraulic Pump Maintenance

Regular maintenance is crucial to ensure the reliable and efficient operation of the Kawasaki KX60 excavator hydraulic pump. A well-maintained pump can last longer and perform better, reducing the risk of downtime and costly repairs. Here are some maintenance tips to keep in mind:

-

Check the hydraulic fluid regularly: The hydraulic fluid plays a crucial role in lubricating the pump and other hydraulic components. Check the fluid level regularly and change it at recommended intervals to prevent contamination and ensure proper lubrication.

-

Inspect the filtration system: The Kawasaki KX60 excavator hydraulic pump comes with a built-in filtration system to ensure the hydraulic fluid is clean and free of contaminants. Inspect the filters regularly and clean or replace them as needed to prevent clogging and maintain optimal performance.

-

Check for leaks: Hydraulic leaks can cause the pump to lose pressure and reduce its efficiency. Inspect the pump and the hydraulic lines for leaks and repair or replace any damaged components.

-

Test the pressure relief valve: The pressure relief valve is a safety feature that protects the hydraulic system from damage in case of overload or system malfunction. Test the valve regularly to ensure it is working correctly and replace it if necessary.

-

Monitor the pump's performance: Keep an eye on the pump's performance and watch for any signs of unusual noise, vibration, or reduced efficiency. These can indicate a problem with the pump or other hydraulic components.

By following these maintenance tips, you can keep the Kawasaki KX60 excavator hydraulic pump in optimal condition and ensure its reliable and efficient performance. It's essential to consult the manufacturer's recommendations and consult with a qualified technician if you encounter any issues or concerns.

Troubleshooting Kawasaki KX60 Excavator Hydraulic Pump Issues

If you're experiencing issues with the hydraulic system on your excavator, the Kawasaki KX60 excavator hydraulic pump may be the culprit. The pump plays a critical role in powering the excavator's attachments, and if it's not functioning correctly, the entire hydraulic system may be compromised.

To troubleshoot the hydraulic system, start by checking the pump for leaks, unusual noise, or other signs of malfunction. If you notice any issues with the pump, it's best to consult a qualified technician to repair or replace it.

Other potential issues with the hydraulic system may include clogged filters, low hydraulic fluid levels, or damaged hydraulic lines. These issues can cause the hydraulic system to operate at a reduced level or even fail completely, so it's essential to address them as soon as possible.

Regular maintenance is the key to preventing these types of issues from occurring. Proper maintenance includes checking the hydraulic fluid levels and changing the fluid at regular intervals, inspecting the hydraulic lines for leaks or damage, and cleaning or replacing the filters as necessary.

It's also crucial to follow the manufacturer's recommendations for maintenance and operation. Improper use or maintenance of the hydraulic system can lead to premature wear and tear on the pump and other hydraulic components, which can result in costly repairs or replacements.

If you're unsure about the cause of an issue with the hydraulic system on your excavator, it's always best to consult a qualified technician. They can diagnose the issue and recommend the appropriate course of action to get your hydraulic system back up and running at optimal performance.

Conclusion

Regular maintenance and inspection of the Kawasaki KX60 excavator hydraulic pump is crucial for ensuring its reliable and efficient operation. Neglecting maintenance can lead to premature wear and tear, decreased performance, and even complete system failure. In this section, we will discuss the best practices for maintaining the Kawasaki KX60 excavator hydraulic pump and troubleshooting common issues.

- Regular Fluid Checks

The hydraulic fluid is a critical component of the hydraulic system, as it powers and lubricates the pump and other hydraulic components. The fluid should be checked at regular intervals to ensure that it is at the correct level and that it is free of contaminants. Any contamination or degradation of the hydraulic fluid can affect the pump's performance and increase wear and tear on other hydraulic components.

- Change Fluid Regularly

Hydraulic fluid should be changed at regular intervals to ensure that it remains clean and free of contaminants. The frequency of fluid changes will depend on the manufacturer's recommendations and the operating conditions of the excavator. A hydraulic fluid analysis can be performed to determine the condition of the fluid and whether it needs to be changed.

- Inspect Filtration System

The Kawasaki KX60 excavator hydraulic pump is equipped with a built-in filtration system that prevents contaminants from entering the hydraulic system. It is essential to inspect and clean or replace the filters regularly to ensure they are functioning correctly. Neglecting the filtration system can cause the hydraulic fluid to become contaminated, which can lead to decreased pump performance and increased wear and tear on hydraulic components.

- Check for Leaks

Leaks in the hydraulic system can lead to reduced pump performance and damage to other hydraulic components. Regularly inspecting the system for leaks is essential to prevent these issues. Any leaks should be repaired immediately to prevent further damage to the system.

- Monitor Performance

The performance of the Kawasaki KX60 excavator hydraulic pump should be regularly monitored to ensure that it is functioning correctly. Monitoring the pump's flow rate, pressure, and temperature can help detect issues early and prevent further damage to the system. Any significant changes in pump performance should be investigated and resolved promptly.

- Consult with a Qualified Technician

If any issues arise with the Kawasaki KX60 excavator hydraulic pump, it is essential to consult with a qualified technician for repair or replacement. Attempting to repair the pump without the proper knowledge and tools can cause further damage to the hydraulic system and lead to safety risks.

In conclusion, regular maintenance and proper care are essential for ensuring the reliable and efficient operation of the Kawasaki KX60 excavator hydraulic pump. Adhering to the manufacturer's recommended maintenance schedule and monitoring the pump's performance can prevent issues and prolong the life of the pump and other hydraulic components.

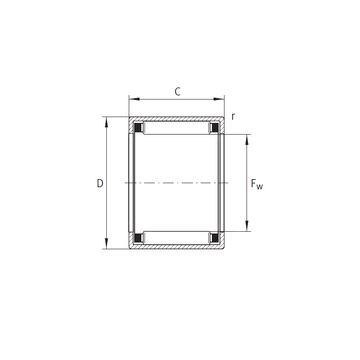

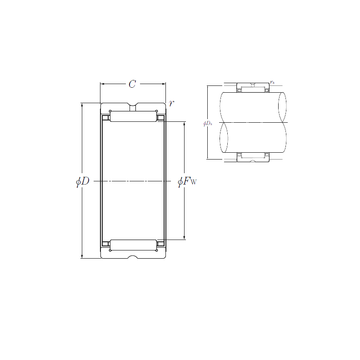

SCE5612 INA Needle Roller Bearings

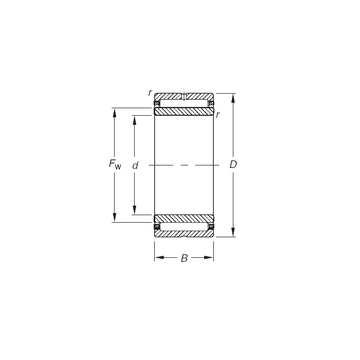

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

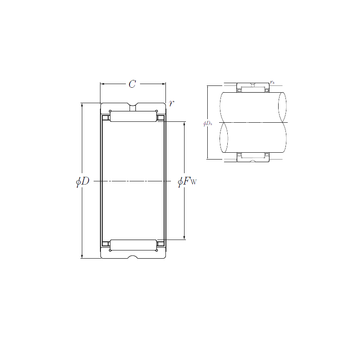

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

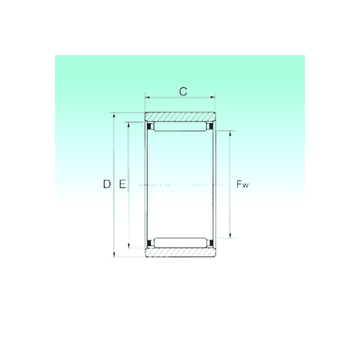

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings