Home> Company News> Types of Bearing Showdown: SKF Group vs. Schaeffler Group vs. Timken Company vs. NSK Ltd. vs. NTN Corporation vs. JTEKT Corporation

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Types of Bearing Showdown: SKF Group vs. Schaeffler Group vs. Timken Company vs. NSK Ltd. vs. NTN Corporation vs. JTEKT Corporation

NOVEMBER 02, 2022Introduction

Welcome to the comprehensive comparison of bearings from leading manufacturers including SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation. we will delve into the significance of bearing selection in various industries and applications, highlighting the key features and offerings of each manufacturer.

Importance of Bearing Selection:

Bearing selection plays a crucial role in the performance and reliability of machinery across diverse industries. From automotive and aerospace to manufacturing and construction, bearings are integral components that facilitate smooth rotational movement, reduce friction, and support heavy loads. The choice of bearings can directly impact factors such as equipment lifespan, energy efficiency, and overall productivity.

Overview of Leading Manufacturers:

SKF Group: As a global leader in bearing technology, SKF Group is renowned for its innovation, reliability, and commitment to quality. With a diverse product portfolio encompassing ball bearings, roller bearings, and specialized solutions, SKF serves industries ranging from automotive and aerospace to wind energy and rail transportation. Their expertise in bearing design, lubrication, and condition monitoring sets them apart as a preferred choice for customers worldwide.

Schaeffler Group: With brands like INA and FAG, Schaeffler Group is a powerhouse in the bearing industry, known for precision engineering and advanced technology. Their comprehensive range of products includes radial and axial bearings, linear motion systems, and automotive components. Schaeffler's focus on research and development drives continuous innovation, making them a trusted partner for demanding applications in automotive, industrial, and aerospace sectors.

Timken Company: A stalwart in the bearing industry for over a century, Timken Company is synonymous with quality, durability, and performance. Specializing in tapered roller bearings, Timken offers a wide array of products catering to automotive, industrial, and aerospace markets. Their engineering expertise, coupled with a legacy of innovation, positions Timken as a preferred supplier for critical applications where reliability is paramount.

NSK Ltd.: NSK Ltd. is a leading manufacturer of bearings, steering systems, and precision components, serving diverse industries such as automotive, industrial machinery, and medical equipment. With a focus on research and development, NSK continually introduces cutting-edge technologies to enhance bearing performance and efficiency. Their product lineup includes ball bearings, roller bearings, and super precision bearings, designed to meet the evolving needs of customers worldwide.

NTN Corporation: NTN Corporation is a global supplier of bearings, constant velocity joints, and precision equipment, catering to industries like automotive, industrial machinery, and construction. Known for their engineering expertise and stringent quality standards, NTN offers a comprehensive range of products designed for reliability and longevity. From miniature bearings to large-size bearings, NTN's solutions address a wide spectrum of applications, ensuring optimal performance and durability.

JTEKT Corporation: JTEKT Corporation, formed from the merger of Koyo Seiko Co. and Toyoda Machine Works, is a leading manufacturer of bearings, automotive steering systems, and machine tools. With a focus on technological innovation and customer satisfaction, JTEKT delivers high-quality bearings and components for automotive, industrial, and railway applications. Their commitment to excellence and continuous improvement reinforces their position as a trusted partner in the global bearing market.

we will conduct a detailed comparison of bearings from these leading manufacturers, evaluating factors such as product range, performance characteristics, industry expertise, and customer support. Stay tuned for insights into the types of bearing offered by each company and how they stack up against one another in various applications.

Material Specifications and Structural Features

we will delve into the material specifications and structural features of bearings manufactured by SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation. Understanding the materials and design characteristics of each brand's bearings is essential for evaluating their performance and suitability for different applications.

|

Manufacturer |

Description |

|

SKF Group |

SKF bearings are renowned for their high-quality materials and precision engineering. The company utilizes premium-grade steel and advanced manufacturing processes to produce bearings with exceptional strength, durability, and corrosion resistance. SKF offers a wide range of bearing types, including ball bearings, roller bearings, and plain bearings, each designed to meet specific application requirements. |

|

Schaeffler Group |

The Schaeffler Group prioritizes innovation and technology in its bearing manufacturing processes. Their bearings are made from high-grade steel alloys and undergo rigorous quality control measures to ensure consistent performance and reliability. Schaeffler specializes in a variety of bearing types, from ball bearings and roller bearings to needle bearings and plain bearings. Their bearings incorporate advanced features such as precision machining, optimized internal geometries, and innovative sealing solutions to enhance performance and longevity. |

|

Timken Company |

Timken bearings are synonymous with durability and reliability, thanks to their robust construction and high-quality materials. The company utilizes specialized steel alloys and advanced heat treatment processes to produce bearings capable of withstanding heavy loads and harsh operating conditions. Timken specializes in tapered roller bearings, cylindrical roller bearings, and spherical roller bearings, offering a comprehensive range of products for various industries. Their bearings feature precision-engineered designs and advanced sealing technologies for superior performance and longevity. |

|

NSK Ltd. |

NSK bearings are known for their precision craftsmanship and innovative design features. The company employs high-quality materials such as vacuum-degassed steel and advanced surface treatment technologies to enhance bearing performance and durability. NSK offers a diverse range of bearing types, including ball bearings, roller bearings, and super precision bearings, designed for applications requiring high speed, accuracy, and reliability. Their bearings incorporate advanced cage designs, raceway profiles, and lubrication systems to optimize performance and minimize friction. |

|

NTN Corporation |

NTN bearings are synonymous with quality and performance, featuring advanced materials and precision engineering. The company utilizes premium-grade steel and proprietary heat treatment processes to ensure the durability and longevity of its bearings. NTN specializes in a wide range of bearing types, including ball bearings, roller bearings, and needle bearings, catering to various industries and applications. Their bearings boast innovative design features such as optimized internal geometries, specialized surface coatings, and advanced sealing solutions for enhanced performance and reliability. |

|

JTEKT Corporation |

JTEKT bearings are known for their rugged construction and exceptional performance in demanding applications. The company utilizes high-quality materials and advanced manufacturing techniques to produce bearings capable of withstanding heavy loads, high speeds, and extreme operating conditions. JTEKT specializes in ball bearings, roller bearings, and automotive bearings, offering a comprehensive range of products for diverse industries. Their bearings feature innovative design elements such as optimized contact geometries, specialized cage materials, and advanced lubrication systems for superior performance and durability. |

This table summarizes the key characteristics and strengths of bearings from each manufacturer.

In summary, each manufacturer employs distinct material specifications and structural features in their bearings, tailored to meet the specific needs of different industries and applications. By understanding these characteristics, customers can make informed decisions when selecting bearings for their equipment, ensuring optimal performance, reliability, and longevity.

Size Range and Compatibility

we will explore the size range and compatibility of bearings offered by SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation. Understanding the size options and compatibility of bearings is crucial for selecting the right components to meet the diverse needs of various applications.

SKF Group:

SKF offers a comprehensive range of bearings in various sizes to cater to different industries and applications. Their product lineup includes ball bearings, roller bearings, and plain bearings, available in standard sizes as well as custom configurations to suit specific requirements. SKF bearings are designed to be compatible with a wide range of machinery, from automotive and industrial equipment to aerospace and wind turbines. With their extensive size range, SKF provides customers with options to optimize performance and efficiency in their applications.

Schaeffler Group:

The Schaeffler Group offers a diverse selection of bearings in a wide range of sizes to accommodate different applications and operating conditions. Their portfolio includes ball bearings, roller bearings, needle bearings, and more, available in standard sizes as well as customized solutions tailored to specific customer needs. Schaeffler's bearings are engineered to deliver superior performance and reliability across various industries, including automotive, aerospace, and industrial machinery. Their comprehensive size range ensures compatibility with diverse equipment and operating environments.

Timken Company:

Timken provides a broad range of bearings in various sizes to meet the demands of different industries and applications. Their offerings include tapered roller bearings, cylindrical roller bearings, spherical roller bearings, and more, available in standard sizes and configurations. Timken bearings are designed for compatibility with a wide range of machinery, from automotive and heavy equipment to industrial machinery and railway systems. With their extensive size range, Timken enables customers to achieve optimal performance and durability in their equipment.

NSK Ltd.:

NSK offers an extensive selection of bearings in diverse sizes to accommodate the needs of different industries and applications. Their product range includes ball bearings, roller bearings, super precision bearings, and more, available in standard sizes and customized configurations. NSK bearings are engineered to deliver high performance and reliability in demanding environments, such as automotive, industrial machinery, and medical equipment. With their broad size range, NSK provides customers with versatile solutions to meet their specific requirements.

NTN Corporation:

NTN provides a wide array of bearings in various sizes to address the needs of different industries and applications. Their product portfolio encompasses ball bearings, roller bearings, needle bearings, and more, available in standard sizes and specialized configurations. NTN bearings are designed for compatibility with a diverse range of equipment, including automotive, industrial machinery, and agricultural implements. With their extensive size range, NTN offers customers flexibility and versatility in selecting bearings for their applications.

JTEKT Corporation:

JTEKT offers a comprehensive lineup of bearings in a broad range of sizes to meet the diverse needs of different industries and applications. Their product range includes ball bearings, roller bearings, automotive bearings, and more, available in standard sizes and customized designs. JTEKT's bearings are engineered for compatibility with various machinery and equipment, providing reliable performance and durability in demanding operating conditions. With their extensive size range, JTEKT ensures that customers can find the right bearings to optimize their applications.

In summary, each manufacturer offers a wide range of bearings in different sizes to suit various industries and applications. Whether standard sizes or custom configurations are required, customers can rely on SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation to provide compatible and high-quality bearings to meet their specific needs.

Installation Guidance

Proper installation of bearings is crucial for ensuring optimal performance, longevity, and reliability of equipment. , we will provide detailed instructions and recommendations for the installation of bearings from SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation. We'll discuss proper mounting techniques, alignment procedures, preload settings, and any unique considerations or tools provided by each brand.

SKF Group:

SKF provides comprehensive installation guidance to ensure the proper mounting of their bearings. Before installation, it's essential to inspect the bearing and surrounding components for any damage or contamination. SKF recommends using clean tools and equipment during the installation process to prevent debris from entering the bearing. Proper alignment is crucial for minimizing stress and maximizing bearing life. SKF offers a range of tools and accessories, such as induction heaters and alignment gauges, to facilitate accurate installation.

Schaeffler Group:

The Schaeffler Group offers detailed installation instructions to ensure the proper handling and mounting of their bearings. Before installation, it's important to clean and inspect the bearing and shaft surfaces for any defects or irregularities. Schaeffler emphasizes the importance of proper alignment and preload adjustment to optimize bearing performance. They provide specialized tools and equipment, such as mounting sleeves and hydraulic nuts, to simplify the installation process and ensure precise alignment.

Timken Company:

Timken provides thorough installation guidance to assist customers in properly mounting their bearings. Before installation, it's essential to clean and lubricate the bearing and shaft surfaces to reduce friction and prevent damage. Timken recommends using precision instruments, such as dial indicators and torque wrenches, to achieve proper alignment and preload settings. They offer a range of mounting accessories and tools, including mounting cups and impact fitting tools, to facilitate the installation process and ensure optimal performance.

NSK Ltd.:

NSK offers detailed installation instructions to guide customers through the proper mounting of their bearings. Before installation, it's important to inspect the bearing and mating surfaces for any signs of damage or contamination. NSK emphasizes the importance of proper handling and storage to prevent premature wear or failure. They provide specialized tools and equipment, such as bearing heaters and fitting tool kits, to assist with accurate alignment and preload adjustment during installation.

NTN Corporation:

NTN provides comprehensive installation guidance to ensure the proper handling and mounting of their bearings. Before installation, it's crucial to clean and inspect the bearing and shaft surfaces for any defects or contamination. NTN recommends using proper fitting tools and equipment, such as bearing pullers and mounting plates, to facilitate the installation process and prevent damage to the bearing or shaft. Proper alignment and preload adjustment are essential for maximizing bearing life and performance.

JTEKT Corporation:

JTEKT offers detailed installation instructions to assist customers in properly mounting their bearings. Before installation, it's important to verify the compatibility of the bearing with the application and operating conditions. JTEKT provides recommendations for proper handling, storage, and mounting procedures to prevent damage or premature failure. They offer specialized tools and equipment, such as hydraulic presses and alignment jigs, to facilitate accurate installation and ensure optimal performance.

In summary, proper installation of bearings is essential for maximizing performance and reliability. Each manufacturer provides detailed guidance and recommendations for the installation of their bearings, along with specialized tools and equipment to facilitate the process. By following these instructions and using the recommended tools, customers can ensure the proper mounting, alignment, and preload settings of bearings from SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation.

Lubrication Practices

Lubrication plays a crucial role in the performance and longevity of bearings. , we will analyze the lubrication recommendations provided by SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation. We'll compare lubrication intervals, types of lubricants recommended, methods of application, and discuss the impact of proper lubrication on bearing performance and longevity.

|

Manufacturer |

Lubrication Recommendations |

|

SKF Group |

SKF Group emphasizes the importance of proper lubrication for maximizing bearing performance and reliability. They provide detailed lubrication recommendations tailored to each bearing type and application. SKF recommends regular lubrication intervals based on operating conditions and load factors. They offer a range of high-quality lubricants, including grease and oil, suitable for various operating temperatures and environments. SKF also provides guidance on proper lubrication methods, such as manual greasing, automatic lubrication systems, and centralized lubrication systems, to ensure adequate lubrication coverage and protection against contamination. |

|

Schaeffler Group |

The Schaeffler Group provides comprehensive lubrication recommendations to ensure optimal bearing performance and longevity. They offer detailed guidance on lubrication intervals, specifying the frequency of relubrication based on operating conditions and application requirements. Schaeffler recommends the use of high-performance lubricants, such as greases and oils, compatible with their bearing materials and operating temperatures. They also provide recommendations for lubrication methods, including manual greasing, automatic lubrication systems, and centralized lubrication systems, to ensure proper lubricant distribution and protection against wear and corrosion. |

|

Timken Company |

Timken Company emphasizes the critical role of proper lubrication in maximizing bearing life and reliability. They provide detailed lubrication guidelines tailored to each bearing type and application, specifying the recommended lubrication intervals and types of lubricants to be used. Timken offers a range of high-quality greases and oils designed to withstand various operating conditions and temperature ranges. They also provide recommendations for lubrication methods, such as manual greasing, automatic lubrication systems, and re-lubrication intervals, to ensure consistent lubrication coverage and protection against contaminants. |

|

NSK Ltd. |

NSK Ltd. offers comprehensive lubrication recommendations to ensure optimal bearing performance and durability. They provide detailed guidelines on lubrication intervals, specifying the frequency of relubrication based on operating conditions and application requirements. NSK recommends the use of high-quality lubricants, such as greases and oils, suitable for their bearing materials and operating environments. They also provide guidance on proper lubrication methods, including manual greasing, automatic lubrication systems, and centralized lubrication systems, to ensure effective lubrication distribution and protection against wear and friction. |

|

NTN Corporation |

NTN Corporation provides detailed lubrication guidance to ensure the proper functioning and longevity of their bearings. They offer recommendations for lubrication intervals based on operating conditions, load factors, and environmental factors. NTN recommends the use of high-quality lubricants, such as greases and oils, specifically formulated for their bearing materials and operating temperatures. They also provide instructions for proper lubrication methods, including manual greasing, automatic lubrication systems, and centralized lubrication systems, to ensure optimal lubrication coverage and protection against contamination. |

|

JTEKT Corporation |

JTEKT Corporation prioritizes proper lubrication practices to enhance bearing performance and reliability. They provide detailed lubrication recommendations tailored to each bearing type and application, specifying the appropriate lubrication intervals and types of lubricants to be used. JTEKT offers a range of high-performance lubricants, including greases and oils, suitable for various operating conditions and temperature ranges. They also provide guidance on proper lubrication methods, such as manual greasing, automatic lubrication systems, and centralized lubrication systems, to ensure consistent lubrication coverage and protection against wear and tear. |

This table summarizes the lubrication recommendations provided by each manufacturer for their bearings.

In summary, proper lubrication is essential for maximizing bearing performance, reliability, and longevity. SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation offer comprehensive lubrication recommendations tailored to their respective bearing types and applications. By following these recommendations and using high-quality lubricants, customers can ensure optimal bearing operation and minimize the risk of premature failure.

Maintenance and Replacement

Proper maintenance is essential for maximizing the lifespan and performance of bearings. , we will provide guidance on routine maintenance practices, monitoring bearing condition, and implementing timely replacements. We'll also compare warranty policies, customer support, and availability of replacement parts offered by SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation.

Routine Maintenance Practices:

Regular maintenance is crucial for ensuring the optimal performance and longevity of bearings. SKF Group recommends periodic inspections of bearings to check for signs of wear, contamination, or lubrication issues. They provide guidelines for proper cleaning, relubrication, and alignment to prevent premature failure. Schaeffler Group emphasizes the importance of regular relubrication and proper storage conditions to maintain bearing integrity. Timken Company offers detailed instructions for periodic inspections and lubrication intervals to extend bearing life. NSK Ltd. provides recommendations for routine maintenance tasks such as bearing relubrication and monitoring operating temperatures. NTN Corporation offers guidance on proper handling and storage practices to prevent damage during maintenance procedures. JTEKT Corporation emphasizes the importance of regular inspections and lubrication to ensure optimal bearing performance.

Monitoring Bearing Condition:

Monitoring bearing condition is essential for detecting signs of wear or damage early on. SKF Group recommends using condition monitoring techniques such as vibration analysis and temperature monitoring to assess bearing health. Schaeffler Group offers advanced monitoring solutions, including online monitoring systems, to detect abnormal operating conditions and predict potential failures. Timken Company provides guidelines for visual inspections and measurement techniques to assess bearing condition. NSK Ltd. offers diagnostic tools and software for analyzing bearing vibration and noise levels. NTN Corporation emphasizes the importance of regular inspections and trend analysis to identify potential issues before they escalate. JTEKT Corporation provides guidance on implementing predictive maintenance strategies to anticipate bearing failures and minimize downtime.

Timely Replacements:

Timely replacement of bearings is crucial for preventing catastrophic failures and minimizing downtime. SKF Group offers recommendations for determining the appropriate replacement intervals based on operating conditions and load factors. Schaeffler Group provides guidelines for assessing bearing condition and determining the optimal replacement timing. Timken Company offers a range of replacement parts and assemblies to facilitate quick and efficient replacements. NSK Ltd. provides technical support and assistance in identifying suitable replacement bearings for specific applications. NTN Corporation offers warranty coverage for defective bearings and assistance in the replacement process. JTEKT Corporation emphasizes the importance of using genuine replacement parts to ensure compatibility and performance.

Comparison of Warranty Policies and Customer Support:

When it comes to warranty policies and customer support, SKF Group offers comprehensive warranty coverage and technical support to assist customers with bearing-related issues. Schaeffler Group provides warranty coverage for their bearings and offers responsive customer support for inquiries and technical assistance. Timken Company stands behind their products with reliable warranty coverage and dedicated customer service. NSK Ltd. offers warranty protection and responsive customer support to address customer concerns promptly. NTN Corporation provides warranty coverage for their bearings and offers customer support to assist with warranty claims and technical inquiries. JTEKT Corporation offers warranty protection and responsive customer support to ensure customer satisfaction.

In summary, proper maintenance practices, monitoring of bearing condition, and timely replacements are essential for maximizing bearing performance and longevity. SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation offer guidance and support to help customers maintain their bearings effectively and address any issues that may arise.

Conclusion

In this comprehensive comparison of bearings from SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation, we have explored various aspects of bearing performance, specifications, maintenance practices, and customer support. Here, we summarize the key findings and offer recommendations for selecting the most suitable bearings for specific application requirements.

Key Findings:

SKF Group: Known for their high-quality bearings and comprehensive technical support, SKF Group offers a wide range of bearings suitable for diverse applications. Their emphasis on innovation and reliability makes them a preferred choice for many industries.

Schaeffler Group: With a strong focus on research and development, Schaeffler Group delivers innovative bearing solutions tailored to meet the evolving needs of customers. Their commitment to quality and performance is reflected in their extensive product range.

Timken Company: Renowned for their precision-engineered bearings and robust designs, Timken Company provides bearings that excel in demanding industrial environments. Their reliability and durability make them a trusted partner in various industries.

NSK Ltd.: NSK Ltd. is known for their technological expertise and advanced bearing solutions. They offer a comprehensive range of bearings designed to deliver superior performance and reliability across diverse applications.

NTN Corporation: NTN Corporation is a leading provider of bearings known for their precision engineering and cutting-edge technologies. Their commitment to quality and customer satisfaction makes them a preferred choice for many industrial applications.

JTEKT Corporation: JTEKT Corporation offers a diverse portfolio of bearings characterized by their durability and performance. Their focus on continuous improvement and customer-centric approach ensures the delivery of high-quality bearings tailored to meet specific customer needs.

Recommendations:

Based on the comparison, selecting the most suitable bearings depends on specific application requirements, operating conditions, and performance criteria. It is essential for users to carefully evaluate factors such as load capacity, speed, temperature, lubrication requirements, and environmental conditions when choosing bearings from SKF Group, Schaeffler Group, Timken Company, NSK Ltd., NTN Corporation, and JTEKT Corporation.

We recommend readers to conduct further research, consult with industry experts, and consider factors such as technical specifications, warranty policies, and customer support before making bearing purchasing decisions. By choosing the right bearings, users can optimize equipment performance, minimize downtime, and enhance overall productivity.

In conclusion, the comparison of bearings from leading manufacturers provides valuable insights into the diverse options available in the market. Each manufacturer offers unique strengths and capabilities, and selecting the most suitable bearings requires careful consideration of various factors to meet specific application needs effectively.

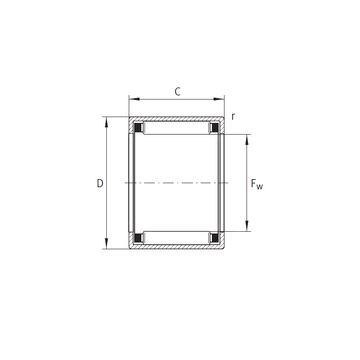

SCE5612 INA Needle Roller Bearings

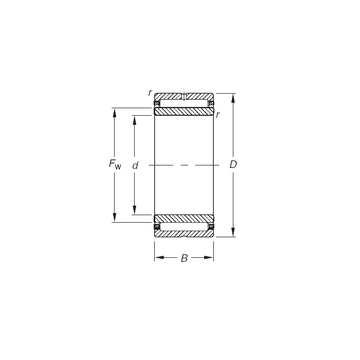

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

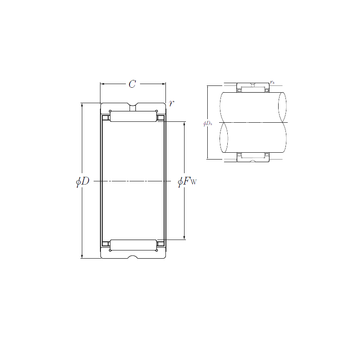

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

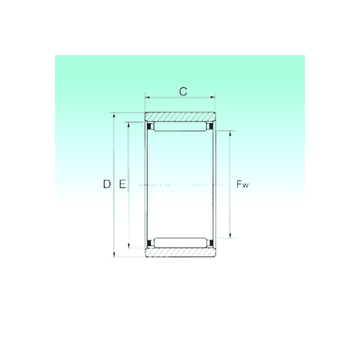

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings