Home> Company News> Unveiling the Versatility of HJ Series in Cylindrical Roller Radial Bearings

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

1 Introduction

In the realm of mechanical engineering, cylindrical roller radial bearings stand as stalwart components, facilitating smooth rotational motion in various applications. These bearings, characterized by their cylindrical shape and ability to support heavy radial loads, are integral in numerous industries, from automotive to aerospace.

Introducing the HJ Series, a remarkable subset within the domain of cylindrical roller radial bearings. The HJ Series distinguishes itself through innovative design features and unparalleled performance, offering a myriad of benefits to industries relying on precision and reliability in their machinery.

Understanding the significance of exploring the versatility of HJ Series in cylindrical roller radial bearings is paramount. Not only does it enhance operational efficiency and performance but also opens avenues for technological advancements and breakthroughs in engineering.

As we delve deeper into the intricacies of cylindrical roller radial bearings and the HJ Series, it becomes evident that these components are not just mere mechanical elements but the backbone of modern machinery, driving progress and innovation across industries.

Cylindrical Roller Radial Bearings, including the renowned HJ Series, represent a cornerstone of modern engineering, providing essential support for heavy radial loads while facilitating smooth rotational motion in a variety of applications. Across the globe, several brands have distinguished themselves in the production of these critical components, each offering unique features and capabilities tailored to specific industrial needs.

Below is a comparison of various brands offering Cylindrical Roller Radial Bearings, including details about their HJ Series:

|

Brand |

Key Features |

Applications |

Advantages |

|

SKF |

- Precision engineering - Advanced materials - Superior performance |

- Automotive - Industrial machinery - Aerospace |

- High durability - Exceptional reliability - Global recognition |

|

Timken |

- Legacy of innovation - Exceptional durability - Efficient operation |

- Automotive - Industrial machinery - Renewable energy |

- Longevity - Broad application range |

|

NSK |

- Precision manufacturing - Reliable performance - Wide application range |

- Automotive - Industrial machinery - Aerospace |

- High precision - Versatility - Global distribution |

|

Schaeffler Group |

- Technological innovation - High-quality components - Reliable operation |

- Automotive - Industrial machinery - Aerospace |

- Technological leadership - Comprehensive product portfolio |

|

NTN Corporation |

- Engineering excellence - Superior materials - Global presence |

- Automotive - Industrial machinery - Renewable energy |

- Engineering expertise - Global support - Wide market acceptance |

In summary, each brand offers unique advantages and capabilities in its Cylindrical Roller Radial Bearings, including their respective HJ Series. Depending on specific application requirements and preferences, industries can choose the brand that best aligns with their needs for performance, reliability, and efficiency.

2 Understanding Cylindrical Roller Radial Bearings

Overview of Cylindrical Roller Bearings

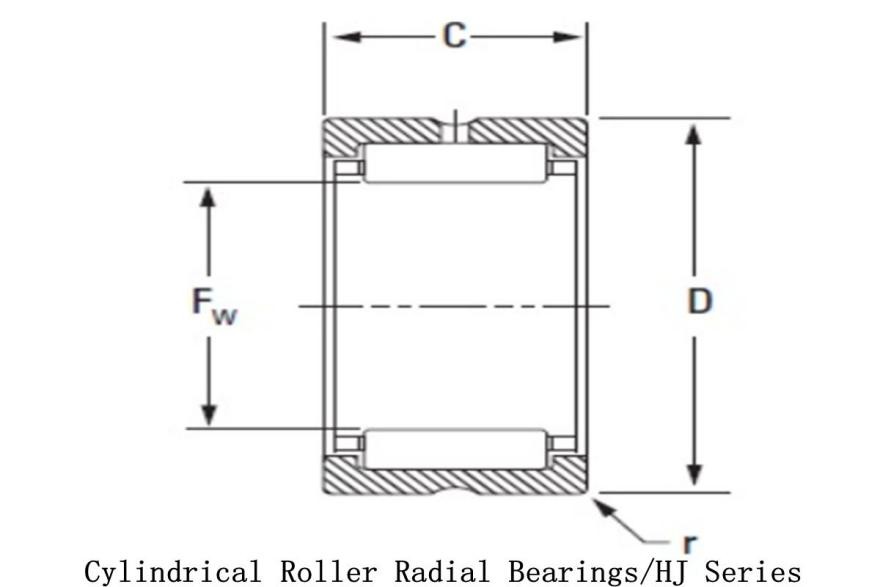

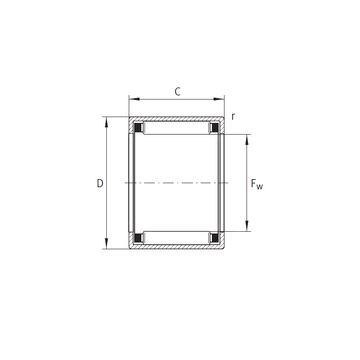

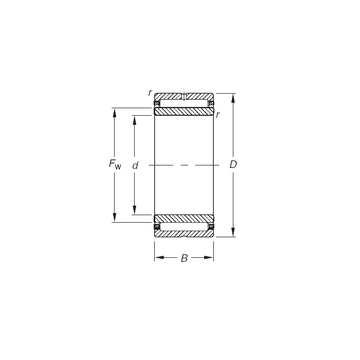

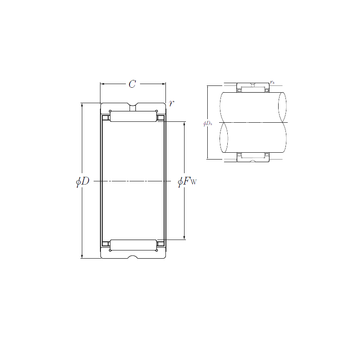

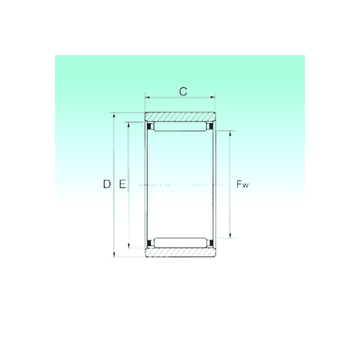

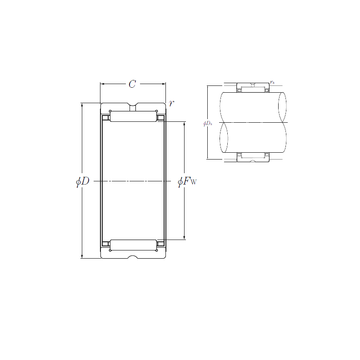

Cylindrical roller radial bearings are crucial components in mechanical systems, providing support for heavy radial loads while allowing for smooth rotational motion. These bearings consist of cylindrical rollers held in place by inner and outer rings, with the roller axis parallel to the axis of the bearing. This design enables them to handle high radial loads efficiently, making them ideal for various applications across industries.

Design Features and Construction

The design of cylindrical roller bearings is characterized by their cylindrical shape, which allows for efficient distribution of load stress along the length of the rollers. They typically feature two rings – an inner ring, which is mounted onto the shaft, and an outer ring, which houses the rollers. The rollers themselves are guided by flanges on the inner ring or ribs on the outer ring, ensuring precise alignment and smooth operation.

In terms of construction, cylindrical roller bearings can be categorized into several types, including single row, double row, and full complement bearings. Each type has its own unique features and benefits, catering to specific application requirements. Additionally, advancements in material technology have led to the development of bearings with enhanced durability, corrosion resistance, and temperature tolerance.

Applications and Industries Utilizing Cylindrical Roller Radial Bearings

Cylindrical roller radial bearings find widespread use across a diverse range of industries and applications. In the automotive sector, they are employed in wheel hubs, transmissions, and engine components, where they provide reliable support and smooth operation. In industrial machinery, these bearings are utilized in equipment such as pumps, compressors, and conveyors, where they contribute to efficient power transmission and motion control.

Moreover, cylindrical roller bearings play a crucial role in the aerospace, construction, and renewable energy sectors, among others. Their versatility and ability to withstand heavy loads make them indispensable in critical machinery and equipment, ensuring optimal performance and reliability.

As industries continue to evolve and innovate, the demand for high-quality cylindrical roller radial bearings remains constant. Manufacturers are constantly striving to develop bearings with improved performance characteristics and enhanced durability, further driving the advancement of this essential component in modern engineering.

This comprehensive understanding of cylindrical roller radial bearings lays the foundation for exploring the versatility and significance of the HJ Series, a specialized subset that promises to revolutionize various applications in the field of mechanical engineering.

3 Exploring the HJ Series

Introduction to HJ Series Bearings

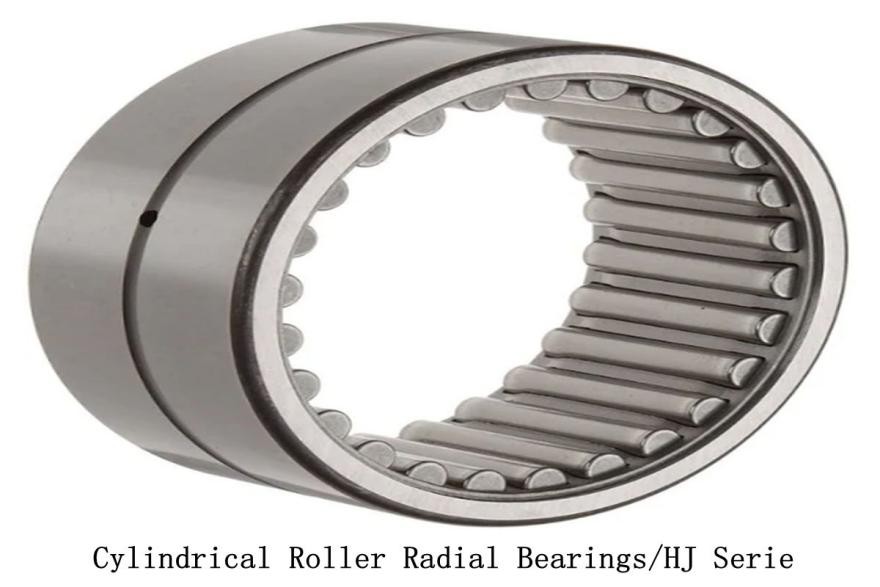

The HJ Series represents a pinnacle of innovation and engineering excellence within the realm of cylindrical roller radial bearings. Developed with meticulous attention to detail and precision, these bearings offer unparalleled performance and reliability across a wide range of applications.

Unique Features and Advantages

|

Feature |

Description |

|

Precision Engineering |

Cylindrical Roller Radial Bearings/HJ Series are meticulously engineered to exacting tolerances, ensuring precise alignment and smooth operation. |

|

Advanced Materials |

Utilization of advanced materials such as high-quality steel and innovative alloys enhances durability, reliability, and load-bearing capacity. |

|

Superior Performance |

HJ Series bearings deliver superior performance, with the ability to withstand heavy radial loads and operate at high speeds without compromising efficiency. |

|

Versatility |

These bearings exhibit versatility, making them suitable for a wide range of applications across various industries, including automotive, industrial machinery, aerospace, and medical equipment. |

|

Exceptional Durability |

With robust construction and advanced sealing mechanisms, HJ Series bearings offer exceptional durability, capable of withstanding harsh operating conditions and prolonged use. |

|

Precision Machining |

Precision machining techniques ensure tight tolerances and smooth surface finishes, minimizing friction, reducing noise, and optimizing performance. |

|

Optimal Lubrication |

The HJ Series incorporates optimized lubrication systems, ensuring proper lubrication distribution and extending bearing life while reducing maintenance requirements. |

|

Industry Expertise |

Manufacturers of HJ Series bearings boast decades of industry expertise, leveraging their knowledge to continually improve design, materials, and performance. |

|

Global Recognition |

Recognized globally for their quality, reliability, and performance, HJ Series bearings have earned the trust of industries worldwide, establishing themselves as a preferred choice. |

Comparative Analysis with Other Bearing Series

When compared to conventional bearing series, such as ball bearings or tapered roller bearings, the HJ Series stands out for its ability to handle higher radial loads with greater precision and reliability. The cylindrical roller design provides a larger contact area between the rollers and the raceways, distributing load stress more evenly and reducing the risk of premature wear and failure.

Moreover, the HJ Series offers superior axial load-carrying capacity compared to other types of bearings, making it particularly well-suited for applications involving combined radial and axial loads. This versatility extends the range of potential applications for HJ Series bearings, allowing them to excel in diverse industrial settings.

In conclusion, the HJ Series represents a paradigm shift in the field of cylindrical roller radial bearings, offering unmatched performance, durability, and versatility. With its innovative design features and superior engineering, the HJ Series sets a new standard for excellence in bearing technology, empowering industries worldwide to achieve greater efficiency and reliability in their machinery.

4 Versatility of HJ Series in Various Applications

|

Automotive Industry Applications

|

The automotive industry relies heavily on precision engineering and reliable components to ensure the smooth operation of vehicles. In this regard, the HJ Series of cylindrical roller radial bearings plays a pivotal role. These bearings are utilized in various automotive applications, including wheel hubs, transmissions, and engine components. Their ability to withstand heavy radial loads and operate at high speeds makes them indispensable in ensuring the performance and safety of vehicles on the road. In the automotive sector, where reliability and efficiency are paramount, the HJ Series stands out for its exceptional durability, precision, and longevity. Whether it's providing support for rotating components or facilitating smooth motion in steering systems, these bearings deliver unparalleled performance, contributing to the overall efficiency and performance of automobiles.

|

|

Industrial Machinery Applications

|

In the realm of industrial machinery, where heavy-duty equipment operates under demanding conditions, the HJ Series of bearings proves to be a reliable and versatile solution. These bearings find application in a wide range of industrial machinery, including pumps, compressors, conveyors, and gearboxes, among others. The HJ Series is prized for its ability to handle heavy radial loads with ease while maintaining precise alignment and low friction operation. This makes it ideal for critical components in industrial machinery, where performance and reliability are non-negotiable. Whether it's supporting rotating shafts or transmitting power efficiently, these bearings excel in diverse industrial applications, contributing to increased productivity and reduced downtime.

|

|

Aerospace Applications

|

In the aerospace industry, where precision, reliability, and safety are paramount, the HJ Series of bearings plays a crucial role in ensuring the smooth operation of aircraft and spacecraft. These bearings are utilized in a wide range of aerospace applications, including landing gear systems, flight control surfaces, and engine components. The aerospace sector demands components that can withstand extreme temperatures, high speeds, and heavy loads, all while maintaining precise performance. The HJ Series meets these requirements with its advanced design features and superior engineering, making it the bearing of choice for aerospace engineers worldwide. Whether it's supporting rotating components in aircraft engines or providing stability in flight control systems, these bearings deliver unmatched performance and reliability in aerospace applications.

|

|

Medical Equipment Applications

|

In the field of medical equipment manufacturing, where precision, reliability, and patient safety are paramount, the HJ Series of bearings finds extensive use in various applications. From diagnostic equipment to surgical instruments, these bearings play a critical role in ensuring the smooth and precise operation of medical devices. The HJ Series is prized for its ability to provide smooth and quiet operation, essential in medical equipment where patient comfort is a priority. Whether it's supporting rotating components in imaging machines or facilitating precise motion in surgical robots, these bearings offer unmatched performance and reliability, contributing to the advancement of medical technology and improving patient care.

|

In conclusion, the versatility of the HJ Series of cylindrical roller radial bearings is evident across a wide range of applications, including automotive, industrial machinery, aerospace, and medical equipment. With their exceptional performance, durability, and reliability, these bearings continue to drive innovation and efficiency in various industries, demonstrating their indispensable role in modern engineering and technology.

5 Future Prospects and Innovations

Potential Advancements in HJ Series Technology

The future of cylindrical roller radial bearings, particularly the HJ Series, holds promise for exciting advancements and innovations. As technology continues to evolve, manufacturers are constantly exploring new avenues to enhance the performance, durability, and efficiency of these critical components.

One potential area of advancement lies in the materials used in manufacturing HJ Series bearings. With ongoing research into advanced alloys and composites, there is the potential to develop bearings that offer even greater strength, durability, and resistance to wear and fatigue. This could result in longer service life and reduced maintenance requirements, ultimately leading to cost savings and improved reliability for end-users.

Furthermore, advancements in manufacturing processes, such as precision machining and surface treatment techniques, are opening up new possibilities for enhancing the performance of HJ Series bearings. By achieving tighter tolerances and smoother surface finishes, manufacturers can minimize friction, reduce noise, and improve overall efficiency, resulting in smoother operation and increased productivity in various applications.

Emerging Trends in Cylindrical Roller Radial Bearings

In addition to advancements in technology, there are several emerging trends shaping the future of cylindrical roller radial bearings. One such trend is the increasing demand for bearings that are environmentally friendly and sustainable. With growing concerns about environmental impact and energy consumption, manufacturers are exploring eco-friendly materials and lubricants that minimize pollution and reduce resource consumption.

Another emerging trend is the integration of smart technologies and sensors into bearing design. By incorporating sensors to monitor factors such as temperature, vibration, and lubrication levels, manufacturers can enable predictive maintenance strategies, allowing for timely intervention and preventing costly downtime. This trend towards predictive maintenance is expected to gain momentum in the coming years, as industries seek to maximize equipment uptime and minimize operational costs.

Opportunities for Further Research and Development

Looking ahead, there are numerous opportunities for further research and development in the field of cylindrical roller radial bearings, particularly within the HJ Series. One area ripe for exploration is the development of bearings optimized for specific applications and operating conditions. By tailoring bearing design and materials to meet the unique requirements of different industries and environments, manufacturers can unlock new opportunities for performance enhancement and customization.

Additionally, research into novel bearing configurations and geometries could lead to breakthroughs in load capacity, friction reduction, and energy efficiency. By pushing the boundaries of traditional bearing design, researchers can uncover new solutions to existing challenges and pave the way for more efficient and reliable machinery in the future.

In conclusion, the future of cylindrical roller radial bearings, particularly the HJ Series, is filled with potential for advancement and innovation. By embracing emerging technologies, trends, and opportunities for further research and development, manufacturers can continue to push the boundaries of what is possible, ensuring that HJ Series bearings remain at the forefront of modern engineering for years to come.

6 Conclusion

In conclusion, the exploration of the HJ Series within the realm of cylindrical roller radial bearings reveals a realm of innovation and promise. Through the lens of this examination, several key findings emerge, shedding light on the significance and potential of these bearings in various industries.

The HJ Series, characterized by its advanced design and exceptional performance, offers a multitude of benefits across a wide range of applications. From automotive to aerospace, industrial machinery to medical equipment, these bearings play a crucial role in ensuring smooth operation, reliability, and efficiency.

The implications of utilizing HJ Series bearings in cylindrical roller radial applications are profound. By harnessing the advanced features and capabilities of these bearings, industries can enhance operational efficiency, minimize downtime, and optimize performance. Whether it's supporting heavy radial loads or facilitating precise motion, the versatility of HJ Series bearings opens up new possibilities for innovation and advancement in engineering.

Looking ahead, the future outlook for HJ Series bearings is promising. As technology continues to evolve and industries strive for greater efficiency and reliability, the demand for these bearings is expected to grow. Manufacturers are poised to continue innovating, pushing the boundaries of design and performance to meet the evolving needs of customers worldwide.

In essence, the HJ Series represents a cornerstone of modern engineering, embodying the principles of precision, reliability, and versatility. As industries continue to evolve and innovate, the role of HJ Series bearings will only become more prominent, driving progress and innovation across a diverse range of applications.

In summary, the versatility and future outlook of HJ Series bearings are bright, offering a glimpse into the endless possibilities of engineering excellence and technological advancement. By embracing these bearings, industries can unlock new levels of performance, efficiency, and reliability, paving the way for a future defined by innovation and progress.

7 FAQs: Common Questions About Cylindrical Roller Radial Bearings/HJ Series

Q1: What are Cylindrical Roller Radial Bearings?

A: Cylindrical roller radial bearings are mechanical components designed to facilitate smooth rotational motion while supporting heavy radial loads. They consist of cylindrical rollers held in place by inner and outer rings, with the roller axis parallel to the axis of the bearing. These bearings are widely used in various industries, including automotive, industrial machinery, aerospace, and medical equipment, due to their ability to handle high radial loads efficiently.

Q2: How do HJ Series bearings contribute to efficiency and reliability?

A: HJ Series bearings contribute to efficiency and reliability through their advanced design features and superior performance characteristics. These bearings are engineered to withstand heavy radial loads while maintaining precise alignment and low friction operation. This results in smoother operation, reduced energy consumption, and extended service life for machinery and equipment. Additionally, the advanced sealing mechanisms of HJ Series bearings provide robust protection against contaminants, ensuring reliable performance even in harsh operating environments.

Q3: Are HJ Series bearings compatible with other bearing components?

A: Yes, HJ Series bearings are designed to be compatible with a wide range of bearing components, including shafts, housings, seals, and lubricants. This compatibility allows for easy integration of HJ Series bearings into existing machinery and equipment, minimizing downtime and simplifying maintenance procedures. However, it is essential to ensure proper installation and alignment of bearing components to maximize performance and longevity.

Q4: How can I ensure the longevity of HJ Series bearings?

A: Ensuring the longevity of HJ Series bearings requires proper installation, lubrication, and maintenance practices. It is crucial to follow the manufacturer's recommendations for installation procedures, including proper alignment and torque specifications. Additionally, regular lubrication of bearings with the appropriate lubricant and monitoring of operating conditions can help prevent premature wear and extend bearing life. Routine inspections and maintenance checks are also essential to identify any issues early and address them promptly to avoid costly downtime.

Q5: What are the benefits of using HJ Series bearings in my application?

A: The benefits of using HJ Series bearings in your application include enhanced performance, reliability, and efficiency. These bearings are designed to withstand heavy radial loads while maintaining precise alignment and low friction operation, resulting in smoother operation, reduced energy consumption, and extended service life for machinery and equipment. Additionally, the advanced sealing mechanisms of HJ Series bearings provide robust protection against contaminants, ensuring reliable performance even in harsh operating environments. Overall, HJ Series bearings offer unmatched versatility and performance, making them ideal for a wide range of applications across various industries.

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings