Home> Company News> Navigating Harsh Conditions: Special Environment Ball Bearings Explained

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Introduction

In today's industrial landscape, machinery and equipment often operate in demanding and diverse environments, ranging from extreme temperatures to corrosive atmospheres. Ensuring the efficient functioning of these systems in such conditions is paramount for productivity and reliability. delves into the realm of Special Environment Ball Bearings (SEBBs), highlighting their significance, design considerations, and applications in navigating harsh conditions.

Importance of Machinery Efficiency in Challenging Environments

Machinery and equipment are the backbone of various industries, from manufacturing plants to aerospace facilities. However, these systems often encounter challenging operating conditions, including high temperatures, moisture, dust, and corrosive substances. In such environments, standard bearings may not suffice, leading to premature failure and costly downtime.

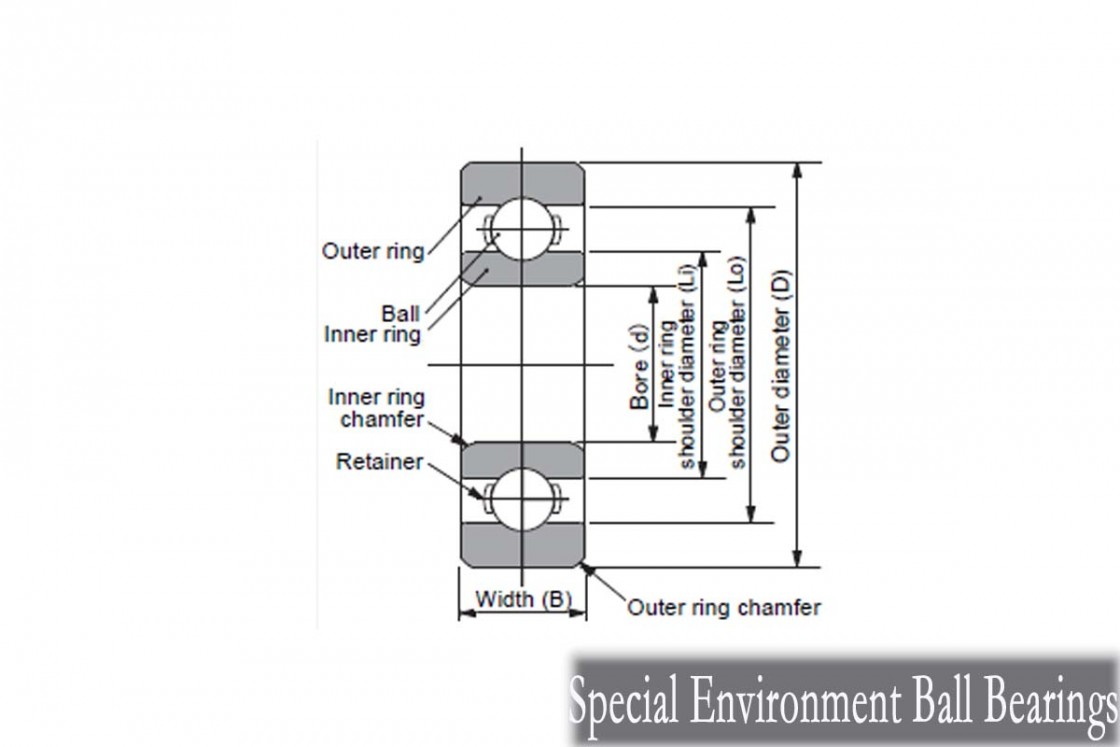

Definition and Significance of Special Environment Ball Bearings

Special Environment Ball Bearings (SEBBs) are engineered to withstand the rigors of extreme operating conditions. Unlike conventional bearings, SEBBs are equipped with advanced materials, seals, and lubricants tailored to specific environmental challenges. These bearings play a crucial role in maintaining the performance and longevity of machinery operating in harsh environments.

Understanding Special Environment Ball Bearings

Special Environment Ball Bearings (SEBBs) represent a critical component in the machinery and equipment landscape, designed to operate reliably in harsh and demanding conditions. we delve into the intricate design features, materials, and applications of SEBBs, providing valuable insights into their functionality and importance in navigating challenging environments.

|

Unique Design Features and Materials |

SEBBs are engineered with a host of unique design features and materials tailored to withstand extreme operating conditions. These bearings often incorporate advanced materials such as stainless steel, ceramic, or special alloys to enhance durability and corrosion resistance. Additionally, SEBBs feature specialized seals and lubricants that provide superior protection against moisture, dust, and other contaminants, ensuring optimal performance and extended lifespan. |

|

Comparison with Standard Ball Bearings |

A key distinguishing factor of SEBBs lies in their specific adaptations to harsh environments compared to standard ball bearings. While standard bearings are suitable for generalpurpose applications, SEBBs are optimized to excel in extreme temperatures, corrosive atmospheres, and environments with high levels of contamination. The enhanced resilience of SEBBs makes them indispensable in industries where standard bearings would quickly degrade or fail. |

|

Industries and Applications |

SEBBs find widespread application across various industries where operating conditions pose significant challenges to conventional bearings. Industries such as aerospace, automotive, marine, and manufacturing rely on SEBBs to ensure the reliability and performance of critical machinery and equipment in adverse environments. From hightemperature furnaces to corrosive chemical processing plants, SEBBs play a crucial role in enabling smooth operation and minimizing downtime. |

Conclusion

Understanding the intricacies of Special Environment Ball Bearings is essential for engineers, maintenance professionals, and industry stakeholders tasked with selecting bearings for challenging operating environments. By leveraging the unique design features and materials of SEBBs, organizations can enhance equipment reliability, minimize maintenance costs, and optimize productivity in the face of harsh conditions. Stay tuned for further exploration of SEBBs in the subsequent sections of this article.

Design Considerations for Special Environment Ball Bearings

In the realm of Special Environment Ball Bearings (SEBBs), meticulous design considerations play a pivotal role in ensuring optimal performance and longevity, especially when subjected to harsh operating conditions. delves into the intricate design aspects, including specialized seals, coatings, lubricants, and materials tailored to safeguard SEBBs from environmental challenges.

Specialized Seals and Coatings

One of the primary design considerations for SEBBs is the implementation of specialized seals and coatings to create a robust barrier against the ingress of contaminants and moisture. These seals, often made from synthetic rubber or thermoplastic materials, form a tight enclosure around the bearing components, preventing harmful substances from infiltrating the internal structure. Additionally, coatings such as platings, anodization, or chemical films provide an additional layer of protection, enhancing corrosion resistance and extending bearing lifespan in corrosive environments.

HighTemperature Lubricants and Bearing Materials

SEBBs operating in extreme temperatures demand highperformance lubricants and bearing materials capable of withstanding thermal stresses without compromising performance. Advanced synthetic lubricants, formulated to maintain viscosity and lubricity across a wide temperature range, are often employed to ensure smooth operation and minimize frictioninduced wear. Furthermore, bearing materials such as stainless steel, ceramic, or specialized alloys exhibit superior heat resistance, enabling SEBBs to function reliably in environments characterized by elevated temperatures or rapid temperature fluctuations.

Advanced Engineering Techniques

To augment the durability and reliability of SEBBs, advanced engineering techniques such as heat treatment and surface treatments are integral parts of the design process. Heat treatment processes like carburizing, nitriding, or induction hardening are utilized to enhance the hardness and fatigue resistance of bearing components, mitigating the risk of premature failure under cyclic loading conditions. Additionally, surface treatments such as shot peening, grinding, or polishing further refine the surface morphology, reducing the propensity for surfaceinitiated failures such as fatigue cracking or fretting corrosion.

Conclusion

Design considerations constitute the cornerstone of Special Environment Ball Bearings, dictating their ability to withstand the rigors of harsh operating conditions with resilience and reliability. By incorporating specialized seals, coatings, lubricants, and materials, engineers can craft SEBBs tailored to specific environmental challenges, ensuring uninterrupted operation and extended service life.

|

Brand |

Features |

Applications |

Advantages |

|

SKF |

Hightemperature tolerance |

Aerospace |

Extensive experience in aerospace applications |

|

|

Corrosionresistant coatings |

Marine |

Globally recognized brand |

|

|

Sealed for protection against contaminants |

Mining |

Innovative bearing solutions |

|

FAG |

Advanced sealing technology |

Aerospace |

Rigorous quality control standards |

|

|

Robust construction for heavyduty applications |

Marine |

Broad range of bearing sizes and types |

|

|

Excellent performance in extreme temperature ranges |

Automotive |

Trusted by automotive OEMs worldwide |

|

NTN |

Specialized lubricants for harsh environments |

Mining |

Strong research and development capabilities |

|

|

Enhanced durability against abrasive particles |

Industrial machinery |

Proven track record in demanding applications |

|

|

Customizable designs for specific industry needs |

Renewable energy |

Global distribution network |

SKF: SKF offers Special Environment Ball Bearings (SEBBs) known for their hightemperature tolerance and corrosionresistant coatings, making them ideal for aerospace, marine, and mining applications. SKF's bearings are sealed for protection against contaminants, ensuring prolonged service life and reliability. With extensive experience in aerospace applications and a globally recognized brand, SKF provides innovative bearing solutions tailored to meet diverse industry requirements.

·

·

FAG: FAG's SEBBs feature advanced sealing technology and robust construction, making them suitable for heavyduty applications in aerospace, marine, and automotive sectors. With excellent performance in extreme temperature ranges and a broad range of bearing sizes and types, FAG bearings are trusted by automotive OEMs worldwide, thanks to rigorous quality control standards.

·

·

NTN: NTN specializes in SEBBs equipped with specialized lubricants for harsh environments and enhanced durability against abrasive particles. These bearings offer customizable designs to meet specific industry needs, making them ideal for mining, industrial machinery, and renewable energy applications. With strong research and development capabilities and a global distribution network, NTN has a proven track record in demanding applications.

Applications and Performance Characteristics

In the domain of Special Environment Ball Bearings (SEBBs), understanding their applications and performance characteristics is essential for grasping their significance across diverse industries and operational environments. delves into the wideranging applications of SEBBs and elucidates their performance attributes under challenging conditions, supported by insightful case studies.

Applications Across Industries

SEBBs find extensive utility across a spectrum of industries, where traditional ball bearings struggle to endure the rigors of harsh operating conditions. In the aerospace sector, SEBBs play a pivotal role in aircraft engines, where they withstand high temperatures, extreme vibrations, and rapid accelerations with unwavering reliability. Similarly, in the marine industry, SEBBs are deployed in propulsion systems, steering mechanisms, and auxiliary equipment, enduring corrosive saltwater environments and heavy dynamic loads. Moreover, in the mining sector, SEBBs facilitate the smooth operation of heavy machinery used in excavation, conveying, and processing operations, where they endure abrasive dust, high shock loads, and continuous operation.

Performance Characteristics

The exceptional performance characteristics of SEBBs enable them to thrive in environments characterized by adverse conditions. These bearings exhibit remarkable resilience to temperature fluctuations, maintaining their structural integrity and performance across a broad thermal range. Furthermore, SEBBs showcase superior resistance to chemical exposure, with specialized seals and coatings preventing degradation from corrosive substances commonly encountered in industrial settings. Additionally, SEBBs excel in bearing heavy loads, thanks to their robust construction and optimized internal geometry, which distribute forces evenly and minimize wear under highstress conditions.

Case Studies and RealWorld Benefits

Case studies serve as compelling demonstrations of the tangible benefits derived from the utilization of SEBBs in enhancing equipment reliability and reducing maintenance costs. By replacing conventional bearings with SEBBs in critical applications, industries have witnessed significant improvements in uptime, operational efficiency, and cost savings. For instance, in the aerospace industry, the adoption of SEBBs has led to prolonged service intervals and reduced downtime, resulting in substantial operational savings and enhanced aircraft availability.

Conclusion

Special Environment Ball Bearings (SEBBs) represent a paradigm shift in bearing technology, offering unparalleled performance and reliability in the face of challenging operating conditions. From aerospace to marine and mining applications, SEBBs continue to redefine industry standards, demonstrating their prowess in sustaining optimal performance under extreme environments. As industries increasingly prioritize equipment reliability and operational efficiency, SEBBs emerge as indispensable components, driving productivity and innovation across diverse sectors.

Installation and Maintenance Best Practices for Special Environment Ball Bearings

Proper installation and maintenance are paramount to ensure the optimal performance and longevity of Special Environment Ball Bearings (SEBBs) in harsh operating conditions. provides comprehensive guidelines and recommendations for installing SEBBs and implementing proactive maintenance strategies to mitigate potential risks and enhance reliability.

Guidelines for Proper Installation

Alignment and Preload Considerations: When installing SEBBs, meticulous attention must be paid to alignment and preload settings to optimize performance and prevent premature wear. Utilize precision alignment tools and follow manufacturer specifications to achieve the desired alignment and preload values.

Sealing and Protection: In harsh environments characterized by contamination or moisture, it's essential to ensure proper sealing and protection of SEBBs. Choose seals and shields specifically designed for challenging conditions to prevent ingress of contaminants and maintain lubrication integrity.

Lubrication Practices: Proper lubrication is critical for the smooth operation of SEBBs. Use lubricants recommended by the bearing manufacturer and adhere to the specified lubrication intervals. Monitor lubricant condition regularly and replenish or replace as necessary to prevent degradation and ensure optimal performance.

Recommendations for Proactive Maintenance

|

Scheduled Inspections |

Establish regular inspection intervals to assess the condition of SEBBs and identify any signs of wear, damage, or degradation. Conduct visual inspections, as well as utilize advanced monitoring techniques such as vibration analysis and temperature monitoring, to detect potential issues early. |

|

Condition Monitoring |

Implement condition monitoring systems to continuously monitor the health of SEBBs during operation. Utilize sensors and predictive maintenance software to detect abnormalities in vibration, temperature, or other parameters, enabling timely intervention before catastrophic failures occur. |

|

Cleaning and Contamination Control |

Develop cleaning procedures and contamination control measures to prevent the buildup of debris or foreign particles that can compromise the performance of SEBBs. Regularly clean and inspect bearing housings, shafts, and surrounding components to maintain cleanliness and integrity. |

Importance of Regular Inspection and Monitoring

Regular inspection and monitoring are essential elements of proactive maintenance practices for SEBBs. By detecting early signs of wear, damage, or contamination, maintenance personnel can take timely corrective actions to prevent costly failures and downtime. Additionally, routine monitoring enables datadriven decisionmaking, facilitating the optimization of maintenance schedules and resource allocation.

In summary, adherence to proper installation procedures and proactive maintenance practices is crucial for maximizing the performance and lifespan of Special Environment Ball Bearings in harsh operating environments. By implementing the guidelines outlined above and prioritizing regular inspection and monitoring, industries can ensure the reliability and efficiency of their machinery, even in the most challenging conditions.

Innovations and Future Trends in Special Environment Ball Bearings

In the rapidly evolving landscape of industrial machinery, Special Environment Ball Bearings (SEBBs) are poised to undergo significant advancements to meet the challenges posed by harsh operating conditions. provides an overview of the ongoing research and development efforts aimed at further enhancing the performance and capabilities of SEBBs, as well as exploring emerging technologies and materials for nextgeneration SEBBs.

Ongoing Research and Development Efforts

Manufacturers and researchers are actively engaged in continuous improvement initiatives to enhance the performance and durability of SEBBs. Through rigorous testing and analysis, engineers are identifying areas for optimization in design, materials, and manufacturing processes. These efforts aim to address specific challenges encountered in extreme environments, such as temperature fluctuations, contamination, and heavy loads.

Emerging Technologies and Materials

One of the most promising avenues for innovation in SEBBs is the exploration of emerging technologies and materials. Nanotechnology, for example, offers the potential to engineer bearings with superior strength, reduced friction, and enhanced resistance to wear and corrosion. By leveraging nanomaterials in bearing design, researchers aim to create SEBBs capable of withstanding even the harshest operating conditions.

Advanced ceramics are another area of interest in the development of nextgeneration SEBBs. These materials exhibit exceptional hardness, high temperature resistance, and superior wear properties compared to traditional bearing materials. By incorporating advanced ceramics into bearing components, manufacturers seek to improve performance, reliability, and longevity, particularly in applications where conventional bearings may falter.

Implications for Addressing Global Challenges

The advancements in SEBB technology hold significant implications for addressing global challenges across various industries. By enhancing the reliability and performance of industrial machinery, SEBBs contribute to increased productivity, reduced downtime, and lower maintenance costs. Moreover, the ability of SEBBs to operate in extreme environments enables their application in critical sectors such as renewable energy, aerospace, and transportation, where reliability is paramount.

Expanding Range of Applications

As SEBB technology continues to evolve, the range of applications for these bearings is expected to expand significantly. From offshore wind turbines to deepsea exploration vessels, SEBBs play a vital role in enabling machinery to operate effectively in the harshest environments on Earth. By pushing the boundaries of innovation, SEBB manufacturers are unlocking new possibilities for industrial machinery across diverse sectors.

In summary, ongoing research and development efforts, coupled with emerging technologies and materials, are poised to revolutionize the field of Special Environment Ball Bearings. These advancements not only promise to enhance the performance and capabilities of SEBBs but also offer solutions to global challenges and open doors to new applications in extreme environments. As industries continue to navigate harsh conditions, SEBBs stand as a beacon of reliability and innovation in the realm of industrial machinery.

Conclusion

In conclusion, Special Environment Ball Bearings (SEBBs) represent a critical advancement in the field of industrial machinery, offering unparalleled performance in navigating harsh operating conditions. we have explored the various aspects of SEBBs, from their design considerations to their applications and future trends. Here, we recapitulate the key features and benefits of SEBBs and underscore their indispensable role in ensuring equipment reliability and performance in challenging environments.

Key Features and Benefits of Special Environment Ball Bearings

SEBBs are engineered with specialized materials and design features, including advanced seals, coatings, and lubricants, to withstand extreme conditions such as high temperatures, contaminants, and moisture ingress. These bearings offer enhanced durability, reliability, and longevity, making them ideal for critical machinery and equipment operating in aerospace, marine, automotive, and other industries.

Critical Role of SEBBs in Ensuring Equipment Reliability

The reliability of industrial machinery is paramount, especially in harsh environments where standard bearings may fail. SEBBs play a crucial role in maintaining equipment uptime and performance, thereby minimizing downtime, reducing maintenance costs, and maximizing productivity. Their ability to withstand extreme conditions ensures uninterrupted operation even in the most challenging environments.

Call to Action for Industries

As industries continue to operate in increasingly demanding environments, the adoption of SEBBs becomes imperative. It is essential for companies to prioritize the integration of SEBBs into their machinery and equipment and invest in ongoing innovation to meet evolving demands. By embracing SEBBs and leveraging their advanced capabilities, industries can enhance operational efficiency, mitigate risks, and stay competitive in today's dynamic market landscape.

In summary, Special Environment Ball Bearings (SEBBs) represent a cornerstone technology for navigating harsh conditions in industrial applications. By recognizing their significance, embracing their benefits, and investing in their continued advancement, industries can achieve unparalleled reliability, performance, and success in challenging operating environments.

FAQs: Common Questions About Special Environment Ball Bearings

As Special Environment Ball Bearings (SEBBs) play a crucial role in various industries, it's natural for questions to arise regarding their functionality, applications, and maintenance. Below, we address some common FAQs to provide clarity and insights into SEBBs.

What are Special Environment Ball Bearings, and how do they differ from standard ball bearings?

Special Environment Ball Bearings (SEBBs) are specially designed bearings capable of operating in challenging environments characterized by extreme temperatures, corrosive substances, high levels of contamination, or other adverse conditions. Unlike standard ball bearings, SEBBs incorporate unique features such as specialized seals, coatings, and materials to withstand harsh environments and maintain performance and reliability.

What industries commonly utilize Special Environment Ball Bearings?

SEBBs find applications across a wide range of industries, including aerospace, automotive, marine, mining, and industrial manufacturing. These bearings are essential in environments where standard bearings would fail to perform adequately due to extreme conditions or exposure to contaminants.

What are the key features of Special Environment Ball Bearings that make them suitable for harsh conditions?

SEBBs possess several key features that enable them to withstand harsh environments effectively. These include:

Specialized Seals and Shields: SEBBs are equipped with seals and shields designed to prevent ingress of contaminants and maintain lubrication integrity, even in challenging conditions.

HighTemperature Lubricants: SEBBs are lubricated with specialized hightemperature greases or oils capable of maintaining lubrication properties at elevated temperatures.

CorrosionResistant Materials: SEBBs utilize materials such as stainless steel, ceramic, or other corrosionresistant alloys to withstand exposure to corrosive substances without compromising performance.

How should Special Environment Ball Bearings be installed and maintained to ensure optimal performance?

Proper installation and maintenance are crucial for maximizing the lifespan and performance of SEBBs in harsh environments. Follow manufacturer guidelines for installation procedures, pay attention to alignment and preload settings, and implement proactive maintenance strategies such as regular inspections and lubrication replenishment to prevent premature wear or damage.

What are the potential benefits of using Special Environment Ball Bearings in extreme environments?

The benefits of using SEBBs in extreme environments include:

Enhanced Reliability: SEBBs offer superior reliability and durability compared to standard bearings, reducing the risk of unexpected failures and downtime.

Extended Lifespan: SEBBs are designed to withstand harsh conditions, resulting in longer bearing life and reduced replacement frequency.

Improved Performance: SEBBs maintain consistent performance even in challenging environments, ensuring the smooth operation of machinery and equipment.

How do Special Environment Ball Bearings contribute to overall equipment reliability and cost savings?

By utilizing SEBBs, industries can improve overall equipment reliability by minimizing the risk of bearing failures and associated downtime. Additionally, the extended lifespan of SEBBs reduces maintenance costs and replacement expenses, resulting in significant cost savings over the long term.

Conclusion

Special Environment Ball Bearings play a vital role in ensuring the reliable operation of machinery and equipment in harsh conditions. By understanding their unique features, applications, and maintenance requirements, industries can leverage the benefits of SEBBs to enhance equipment performance, reliability, and costeffectiveness.

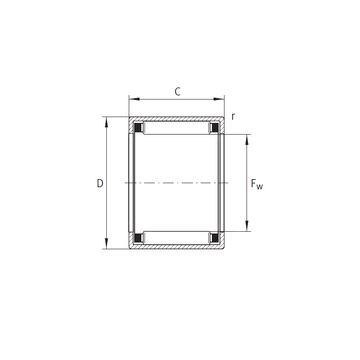

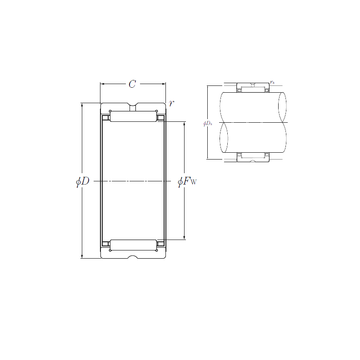

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

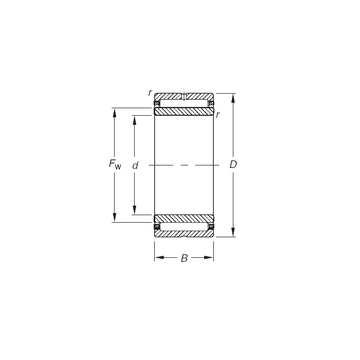

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

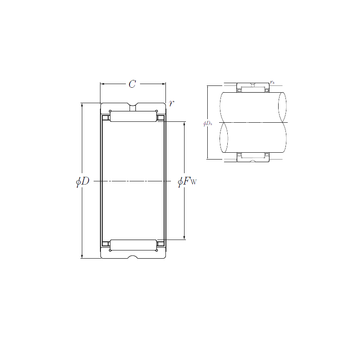

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings