Home> Company News> How To Set Up A Hydraulic Braking System

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Hydraulic braking systems are widely used in various vehicles, from cars to heavy-duty trucks, and even airplanes. These systems are essential for providing reliable and efficient braking performance, which is crucial for safe operation. In this guide, we will discuss the importance of hydraulic braking systems, their components, and how to set them up and maintain them for optimal performance.

Hydraulic braking systems work by converting the pressure applied to the brake pedal into hydraulic pressure, which is then transmitted to the brake calipers. The calipers then apply force to the brake pads, which in turn press against the rotors, causing the wheels to slow down or stop. This process relies on several components working together seamlessly to provide effective braking performance.

Understanding the components of hydraulic braking systems is crucial for proper setup and maintenance. The main components of a hydraulic braking system include the master cylinder, brake lines, brake calipers, brake pads, and brake fluid. These components work together to create the hydraulic pressure needed to stop the vehicle.

Proper hydraulic setup is crucial for reliable and efficient braking performance. The setup process involves several steps, including bleeding the brake lines, checking for leaks, and ensuring that all components are properly installed and tightened. Regular maintenance and testing of the hydraulic system are also important to ensure that the system is working correctly and prevent any potential issues.

Understanding Hydraulic Braking System

A hydraulic braking system is a type of braking system that uses hydraulic pressure to activate the brakes. The system consists of various components that work together to slow down or stop a vehicle.

When the brake pedal is pressed, it creates a force that is transferred to the master cylinder. The master cylinder then converts the force into hydraulic pressure, which is transmitted through brake lines to the brake calipers. The calipers then apply pressure to the brake pads, which press against the brake rotor or drum, creating friction and slowing down or stopping the vehicle.

There are different types of hydraulic braking systems, including disc brakes and drum brakes. Disc brakes are more commonly used in modern vehicles and use a hydraulic system to press brake pads against a brake rotor. Drum brakes, on the other hand, use a hydraulic system to press brake shoes against a brake drum.

Proper setup and maintenance of the hydraulic braking system is crucial for the safe and efficient operation of a vehicle. Understanding how the system works and the different types of hydraulic braking systems can help vehicle owners and technicians identify problems and perform necessary repairs or maintenance.

Components of Hydraulic Braking System

The hydraulic braking system consists of various components that work together to stop a vehicle. Understanding the different components and their functions is crucial for the proper functioning of the system. Let's take a closer look at each component:

-

Master Cylinder: The master cylinder is the main component of the hydraulic braking system. It converts the force exerted by the brake pedal into hydraulic pressure. The hydraulic pressure generated by the master cylinder is then transmitted through the brake lines to the brake calipers.

-

Brake Lines: The brake lines are tubes that carry brake fluid from the master cylinder to the brake calipers. They are usually made of steel or rubber and can withstand high pressure. Brake lines should be regularly inspected for cracks, corrosion, or other signs of wear and tear.

-

Brake Calipers: Brake calipers are mounted on the brake rotors and are responsible for pressing the brake pads against the rotor to slow down or stop the vehicle. They are equipped with pistons that are activated by the hydraulic pressure transmitted through the brake lines.

-

Brake Pads: Brake pads are made of friction material and are designed to press against the brake rotor when the brakes are applied. They absorb the heat generated during the braking process and wear out over time. Worn-out brake pads should be replaced immediately to ensure proper braking performance.

-

Brake Fluid: Brake fluid is the medium that transmits hydraulic pressure from the master cylinder to the brake calipers. It is a special type of fluid that is designed to withstand high temperatures and pressure. The brake fluid level should be regularly checked, and the fluid should be replaced as per the manufacturer's recommendations.

Proper maintenance of all these components is essential to ensure the optimal functioning of the hydraulic braking system. Neglecting maintenance or failing to replace worn-out components can result in decreased braking performance and even brake failure, which can lead to accidents.

Hydraulic Braking System Setup

Setting up a hydraulic braking system can seem daunting, but with the right tools and knowledge, it can be done easily and effectively. Here is a step-by-step guide to setting up a hydraulic braking system:

Step 1: Gather the necessary tools and materials.

Before you begin setting up your hydraulic braking system, make sure you have all the necessary tools and materials. These may include a wrench, pliers, tubing cutter, brake fluid, and a hydraulic brake line kit.

Step 2: Install the master cylinder.

The master cylinder is the heart of the hydraulic braking system, as it generates the hydraulic pressure that activates the brakes. To install the master cylinder, start by positioning it in the engine bay or cabin and securing it in place using mounting bolts.

Step 3: Install the brake lines.

The brake lines carry the brake fluid from the master cylinder to the brake calipers. Start by cutting the brake lines to the appropriate length using a tubing cutter. Next, attach the brake lines to the master cylinder using flare fittings, and run them along the frame of the vehicle to the brake calipers.

Step 4: Install the brake calipers and pads.

The brake calipers and pads are responsible for clamping down on the brake rotors to slow down or stop the vehicle. To install them, start by positioning the calipers in place and securing them using mounting bolts. Next, insert the brake pads into the calipers, making sure they are properly aligned with the brake rotors.

Step 5: Fill the brake lines with fluid.

After installing all the components, it's time to fill the brake lines with brake fluid. Start by filling the master cylinder with brake fluid and then use a brake bleeding kit to pump the fluid through the brake lines until all air bubbles have been removed.

Step 6: Test the hydraulic braking system.

Once the brake lines are filled with fluid, it's important to test the hydraulic braking system to ensure it's working correctly. To do this, pump the brakes several times and then test the vehicle's braking performance at different speeds.

By following these steps, you can set up a hydraulic braking system that is effective and reliable. However, it's important to note that improper installation can lead to brake failure and other safety hazards, so it's always best to consult a qualified mechanic or technician if you're unsure about any aspect of the installation process.

Testing and Adjusting the Hydraulic Braking System

Testing the hydraulic braking system is a crucial step in ensuring that the system is functioning correctly and efficiently. Proper testing should be conducted after the hydraulic system setup and also regularly during maintenance procedures.

There are several tests that can be conducted to ensure the hydraulic braking system is functioning correctly. These tests include the brake pedal feel test, the brake bleeding test, and the brake pad wear test.

The brake pedal feel test is conducted to ensure that the brake pedal has the proper amount of resistance when it is pressed. The pedal should feel firm when pressed, and the resistance should increase as the pedal is pressed further. If the pedal feels spongy or soft, this could indicate air in the brake lines or a problem with the brake master cylinder.

The brake bleeding test is used to remove any air that may have entered the brake lines during the hydraulic setup. Air in the brake lines can reduce the effectiveness of the brakes and cause the pedal to feel spongy or soft. The brake bleeding test involves bleeding the brake lines to remove any air bubbles and ensure that the brake fluid is circulating correctly.

The brake pad wear test is used to determine the condition of the brake pads. Worn brake pads can reduce the effectiveness of the braking system and increase stopping distance. To perform the brake pad wear test, the brake pads must be removed from the calipers and inspected for wear.

After conducting the necessary tests, adjustments may need to be made to the hydraulic braking system. Adjustments can include adjusting the brake pedal height, adjusting the brake calipers, or changing the brake fluid.

Adjusting the brake pedal height involves adjusting the position of the brake pedal to ensure that it is at the proper height for the driver. This adjustment can be made using the adjustment nut located on the brake booster.

Adjusting the brake calipers involves adjusting the position of the calipers to ensure that the brake pads are making proper contact with the rotor. This adjustment can be made using the adjustment bolts located on the caliper.

Changing the brake fluid is necessary when the brake fluid becomes contaminated or breaks down over time. This can occur due to moisture or heat buildup in the system. Brake fluid should be changed every 2-3 years, or as recommended by the vehicle manufacturer.

By regularly testing and adjusting the hydraulic braking system, you can ensure that your vehicle's brakes are functioning correctly and safely. Properly functioning brakes are essential for safe driving and can help prevent accidents and injuries.

Maintenance and Troubleshooting

Proper maintenance and timely troubleshooting are critical for the efficient and reliable operation of a hydraulic braking system. Neglecting maintenance can result in reduced system performance, while ignoring problems can lead to dangerous situations on the road. In this section, we will discuss the importance of regular maintenance and troubleshooting techniques for hydraulic braking systems.

Importance of Regular Maintenance

Regular maintenance is essential to keep the hydraulic braking system in optimal condition. Maintenance tasks include inspection, cleaning, lubrication, and replacement of worn-out components. A well-maintained hydraulic system will operate more efficiently, provide better stopping power, and reduce the risk of system failure.

One of the most critical maintenance tasks is to check the brake fluid level regularly. Low brake fluid levels can result in reduced braking power, which can be dangerous in emergency situations. Also, brake fluid is hygroscopic, which means that it absorbs moisture over time, leading to a reduction in its boiling point. This can cause the brake fluid to boil and produce gas bubbles when subjected to high temperatures, resulting in a loss of brake performance. Therefore, it is crucial to replace brake fluid periodically to maintain the correct level and avoid moisture buildup.

Another critical maintenance task is to inspect the brake pads and rotors for wear and damage. Worn-out brake pads can reduce the system's stopping power and cause brake noise, while damaged rotors can result in uneven braking and vibration. Regular inspection of these components can help detect any issues early and prevent further damage to the system.

Common Problems and Solutions

Despite regular maintenance, hydraulic braking systems can develop problems that affect their performance. Some of the most common problems include soft or spongy brake pedals, brake drag, and uneven braking. These problems can be caused by various issues, such as air in the brake lines, worn-out brake pads, and damaged calipers.

One of the most common problems is a soft or spongy brake pedal. This problem can be caused by air in the brake lines, which can result from improper bleeding of the system or a leak in the lines. To fix this issue, the brake lines must be bled to remove any air trapped in the system. A leak in the lines must be fixed before bleeding the system to avoid reintroducing air into the lines.

Another common problem is brake drag, which occurs when the brakes do not release completely after the pedal is released. Brake drag can be caused by various factors, such as a seized caliper piston, damaged brake line, or malfunctioning master cylinder. To fix this problem, the cause of the drag must be identified and repaired or replaced as necessary.

Uneven braking is another common problem in hydraulic braking systems. This problem can be caused by uneven wear of brake pads, damaged or warped rotors, or a malfunctioning caliper. To fix this issue, the brake pads and rotors must be inspected for wear and damage, and any worn-out or damaged components must be replaced.

Troubleshooting Tips

When troubleshooting a hydraulic braking system, it is essential to follow proper safety procedures to prevent accidents and injuries. Always wear protective gear, such as gloves and eye protection, and never work on the system when the engine is running. Here are some troubleshooting tips to help you diagnose and fix hydraulic braking system problems:

-

Start by checking the brake fluid level and condition. Low fluid levels or contaminated fluid can cause various braking issues.

-

Inspect the brake pads and rotors for wear and damage. Worn-out or damaged components can affect braking performance.

-

Check the brake lines for leaks, damage, or blockages. A blocked or damaged line can prevent the brake fluid from flowing correctly.

-

Check the calipers for leaks or damage. A damaged caliper can cause uneven braking or brake drag.

-

Bleed

Conclusion

Hydraulic braking systems are an essential component of modern vehicles, providing reliable and efficient stopping power. A hydraulic braking system operates by using fluid pressure to activate the brake calipers, which in turn apply friction to the brake rotors or drums, ultimately stopping the vehicle. Proper setup and maintenance of hydraulic braking systems are critical for optimal performance and safety.

In this guide, we have discussed the importance of hydraulic braking systems, the components involved in the system, how they work, and the setup and maintenance process. We have also covered the importance of testing and adjusting the system as per requirements and how to troubleshoot common problems.

A hydraulic braking system works by applying fluid pressure to the brake calipers, which, in turn, apply friction to the brake rotors or drums, eventually stopping the vehicle. There are different types of hydraulic braking systems, including disc brakes, drum brakes, and anti-lock braking systems (ABS). Each system has a different working mechanism, but the basic principle remains the same.

Proper hydraulic setup involves setting up the master cylinder, brake lines, brake calipers, brake pads, and brake fluid. The setup process requires a step-by-step approach, and it is essential to follow the manufacturer's instructions or consult with a qualified technician. Once the setup is complete, it is crucial to test the hydraulic system to ensure proper functionality and adjust the system as per requirements.

Regular maintenance of the hydraulic braking system is critical for optimal performance and safety. Maintenance procedures include checking the brake fluid level and quality, inspecting the brake pads and calipers, cleaning the brake rotors or drums, and bleeding the brake lines. Regular maintenance can help prevent common problems such as brake fade, brake noise, and brake drag.

In case of any problems with the hydraulic braking system, it is important to troubleshoot the issue promptly. Common problems include a soft or spongy brake pedal, brake fade, brake noise, and brake drag. Troubleshooting techniques may include checking the brake fluid level and quality, inspecting the brake pads and calipers, checking the brake lines for leaks or damage, and bleeding the brake lines.

In conclusion, a properly set up and maintained hydraulic braking system is crucial for optimal performance and safety. By understanding the importance of hydraulic braking systems, the components involved, and the setup and maintenance process, vehicle owners and technicians can ensure reliable and efficient stopping power. Regular testing, adjusting, and troubleshooting of the hydraulic braking system can help prevent common problems and ensure maximum safety and performance.

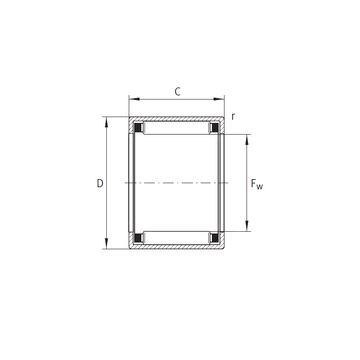

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

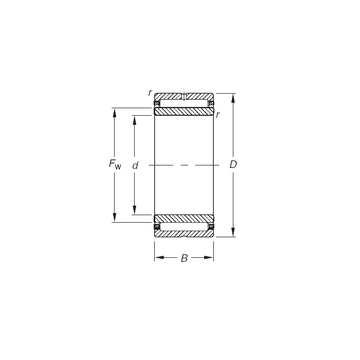

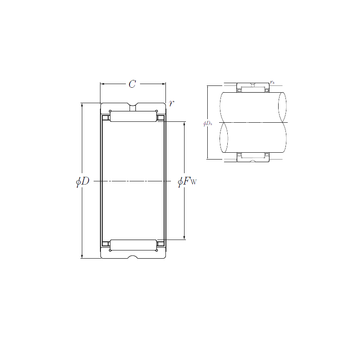

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

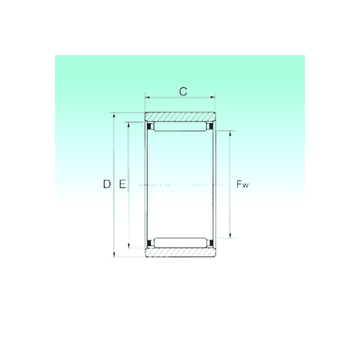

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings